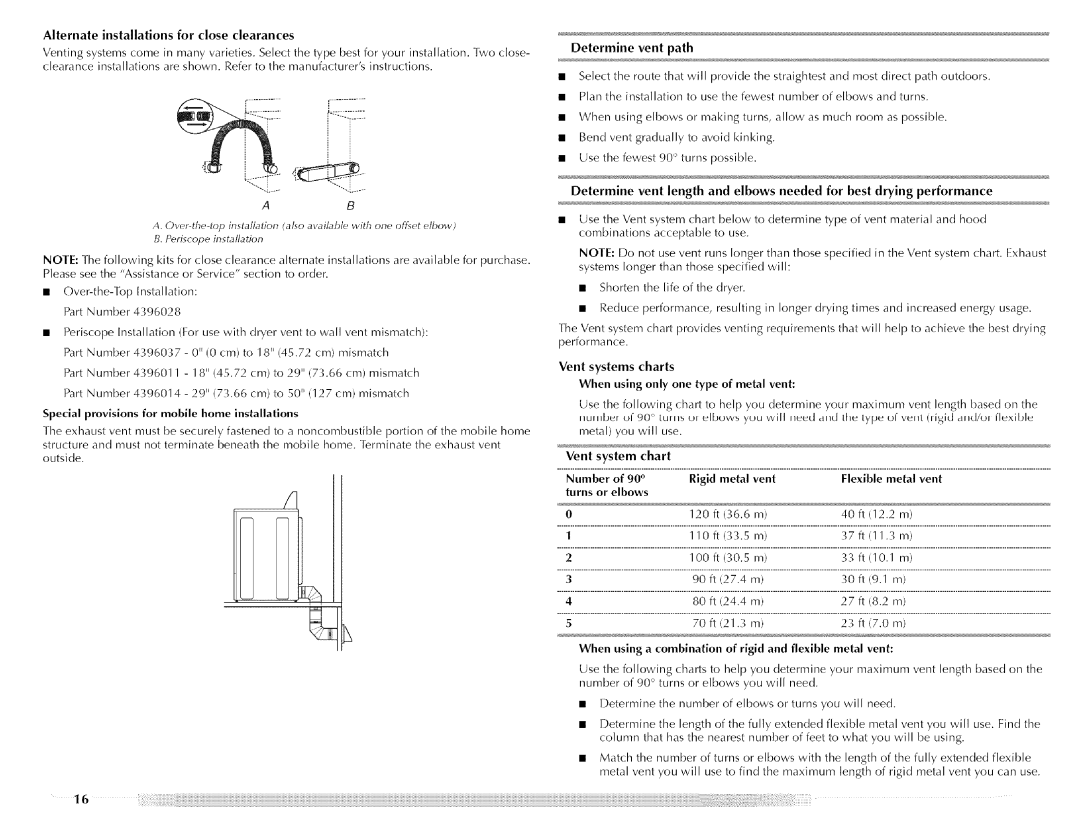

Alternate installations for close clearances

Venting systems come ill many varieties. Select the type best for your installation. Two close- clearance installations are shown. Refer to the manufacturer's instructions.

AB

A.

B. P_'riscope installation

NOTE: The following kits for close clearance alternate installations are available for purchase. Please see the "Assistance or Service" section to order.

•

Part Number 4_96028

•Periscope Installation (For use with dryer vent to wall vent mismatch/: Part Number 4396037 - 0" (0 cm) to 18" (45.72 cm) mismatch

Part Number 4396011 - 18" (45.72 cm) to 29" (73.66 cm) mismatch Part Number 4396014 - 29" (73.66 cm) to 50" (127 cm) mismatch

Special provisions for mobile home installations

lhe exhaust vent must be securely fastened to a noncombustible portion of the mobile home structure and must not terminate beneath the mobile home. erminate the exhaust vent outside.

S

Determine vent path

•Select the route that will provide the straightest and most direct path outdoors,

•Plan the installation to use the fewest number of elbows and turns.

•When using elbows or making turns, allow as much room as possible.

•Bend vent gradually to avoid kinking.

•Use the fewest 90 ° turns possible.

Determine vent length and elbows needed for best drying performance

•Use the Vent system chart below to determine type of vent material and hood

combinations acceptable to use.

NOTE: Do not use vent runs longer than those specified in the Vent system chart. Exhaust systems longer than those specified will:

•Shorten the life of the dryer.

•Reduce performance, resuhing in longer drying times and increased energy usage.

[he Vent system chart provides venting requirements that will help to achieve the best drying performance.

Vent systems charts

When using only one type of metal vent:

Use the following chart to help you determine your maximum vent length based on the number _1"90 _'turu_ ur elb_w_ yuu will need and ttl_ type ul veuL (ri:4id arld/ur flexibl_, metal) you will use.

Vent | system | chart |

|

|

|

|

|

|

|

.............................................................................................................................................................................................................................. |

| ||||||||

Number of | 90 ° | Rigid metal | vent | Flexible metal vent | |||||

turns | or elbows |

|

|

|

|

|

|

| |

0 |

|

| 120 | ft (36.6 | m) | 40 | ft | (12.2 | m) |

.....i |

| ii0iiZ- Tmi |

|

|

| ||||

.............................................................................................................................................................................................................................. |

| ||||||||

2 |

|

| 100 | ft Iq0.5 | m) | 3% ft | (10.1 | m) | |

.............................................................................................................................................................................................................................. |

| ||||||||

3 |

|

| 90 | ft (27.4 | m) | 30 | ft | (9.1 | m/ |

.............................................................................................................................................................................................................................. |

| ||||||||

4 |

|

| 80 | ft (24.4 | m) | 27 | ft | (8.2 | m) |

.............................................................................................................................................................................................................................. |

| ||||||||

5 |

|

| 70 | ft (21.3 | m) | 23 | ft | (7.0 | m) |

When using a combination of rigid and flexible metal vent:

Use the following charts to help you determine your maximum vent length based on the number of 90 ° turns or elbows you will need.

•Determine the number of elbows or turns you will need.

•Determine the length of the fully extended flexible metal vent you will use. Find the column that has the nearest number of feet to what you will be using.

•Match the number of turns or elbows with the length of the fully extended flexible metal vent you will use to find the maximum length of rigid metal vent you can use,

16