TRANSDUCER POSITIONING

As the transducers for the Portaflow 216 are clamped to the outside surface of the pipe, the meter has no way of determining exactly what is happening to the liquid. The assumption therefore has to be made that the liquid is flowing uniformly along the pipe either under fully turbulent conditions or under laminar flow conditions. Further it is assumed that the flow velocity profile is uniform for 360° around the pipe axis.

Figure 8:- A uniform profile as compared to a distorted profile.

“A”“B”

The difference between (a) and (b) is that the Mean Velocity of the flow across the pipe is different and because the Portaflow 216 expects a uniform flow as in (a), the distorted flow as in (b) will give measurement errors which cannot be predicted or be compensated.

Flow profile distortions result from upstream disturbances such as bends, tees, valves, pumps and other similar obstructions. To ensure a uniform profile the transducers must be mounted far enough away from any cause of distortion such that it no longer has an effect.

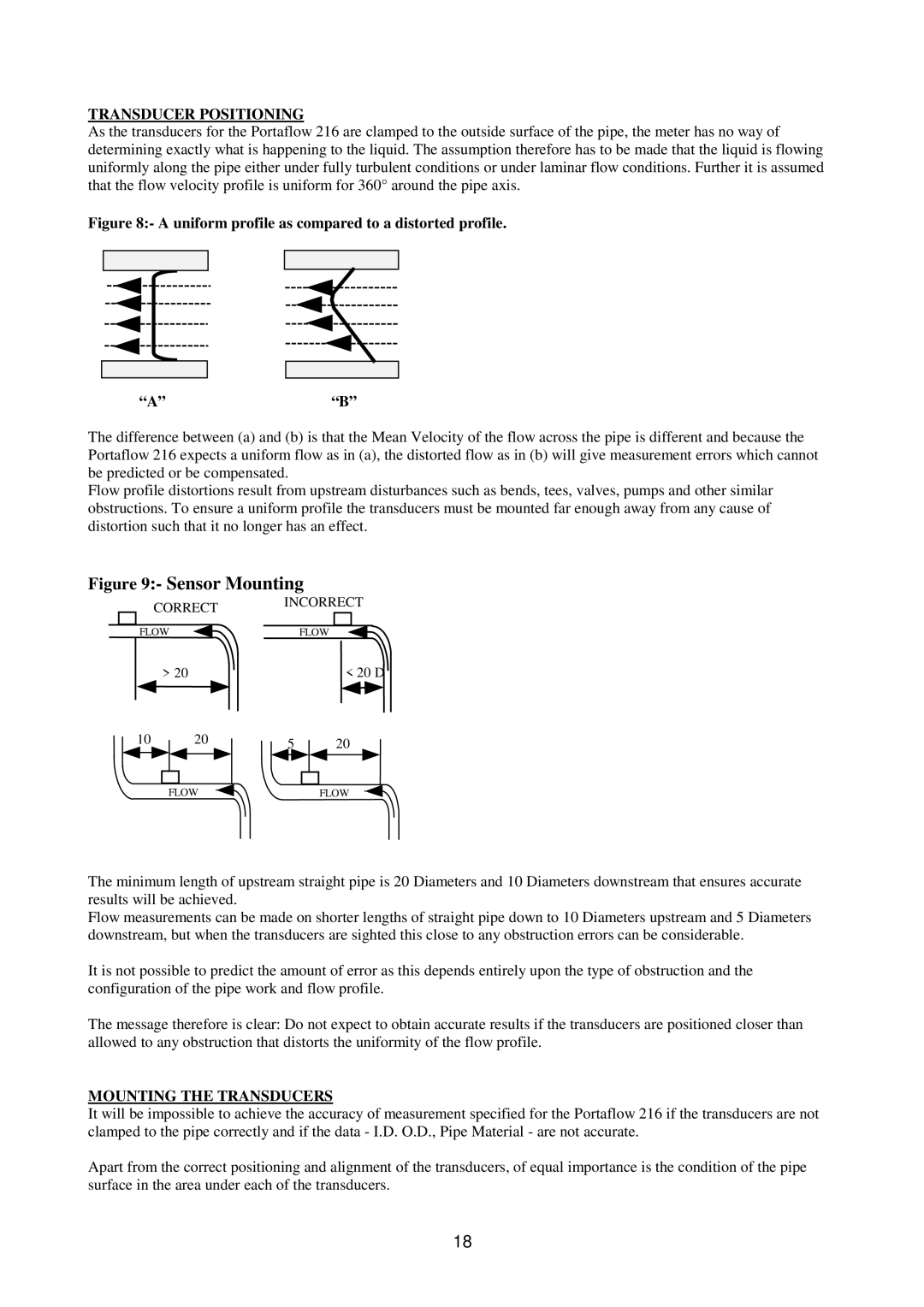

Figure 9:- Sensor Mounting

CORRECT INCORRECT

FLOWFLOW

> 20 | < 20 D |

10

20

5 20

FLOWFLOW

The minimum length of upstream straight pipe is 20 Diameters and 10 Diameters downstream that ensures accurate results will be achieved.

Flow measurements can be made on shorter lengths of straight pipe down to 10 Diameters upstream and 5 Diameters downstream, but when the transducers are sighted this close to any obstruction errors can be considerable.

It is not possible to predict the amount of error as this depends entirely upon the type of obstruction and the configuration of the pipe work and flow profile.

The message therefore is clear: Do not expect to obtain accurate results if the transducers are positioned closer than allowed to any obstruction that distorts the uniformity of the flow profile.

MOUNTING THE TRANSDUCERS

It will be impossible to achieve the accuracy of measurement specified for the Portaflow 216 if the transducers are not clamped to the pipe correctly and if the data - I.D. O.D., Pipe Material - are not accurate.

Apart from the correct positioning and alignment of the transducers, of equal importance is the condition of the pipe surface in the area under each of the transducers.

18