If the Portaflow 216 is to be used on laminar flow applications it will be necessary to calculate the Reynolds No for each application. To calculate the Reynolds No it is necessary to know the Kinematic viscosity in Centistokes; the flow velocity and the pipe inside diameter. Please follow the table below

To calculate Re use the following formula: -

Re = | dv | (7730) | or | Re = | d 1 | v1 | (1000) | ||

υ | 1 | υ | 1 | ||||||

|

|

|

|

| |||||

Where

d= inside pipe diameter in inches

d 1 = inside pipe diameter in millimetres

v= velocity in feet/second

v1 = velocity in metres/second

υ1 = Kinematic viscosity in centistokes

MAXIMUM FLOW

The maximum flow is dependent on the velocity and pipe size.

APPLICATION TEMPERATURE

On any application whose operating temperature is either above or below ambient temperature ensure that the transducers reach and are maintained at the application temperature before undertaking a measurement.

When applying the transducers to low temperature applications do not allow the pipe surface to ice up between the transducer and the pipe wall. The ice will force the block away from the pipe wall and consequently you will lose the signal.

DIAGONAL MODE SETUP

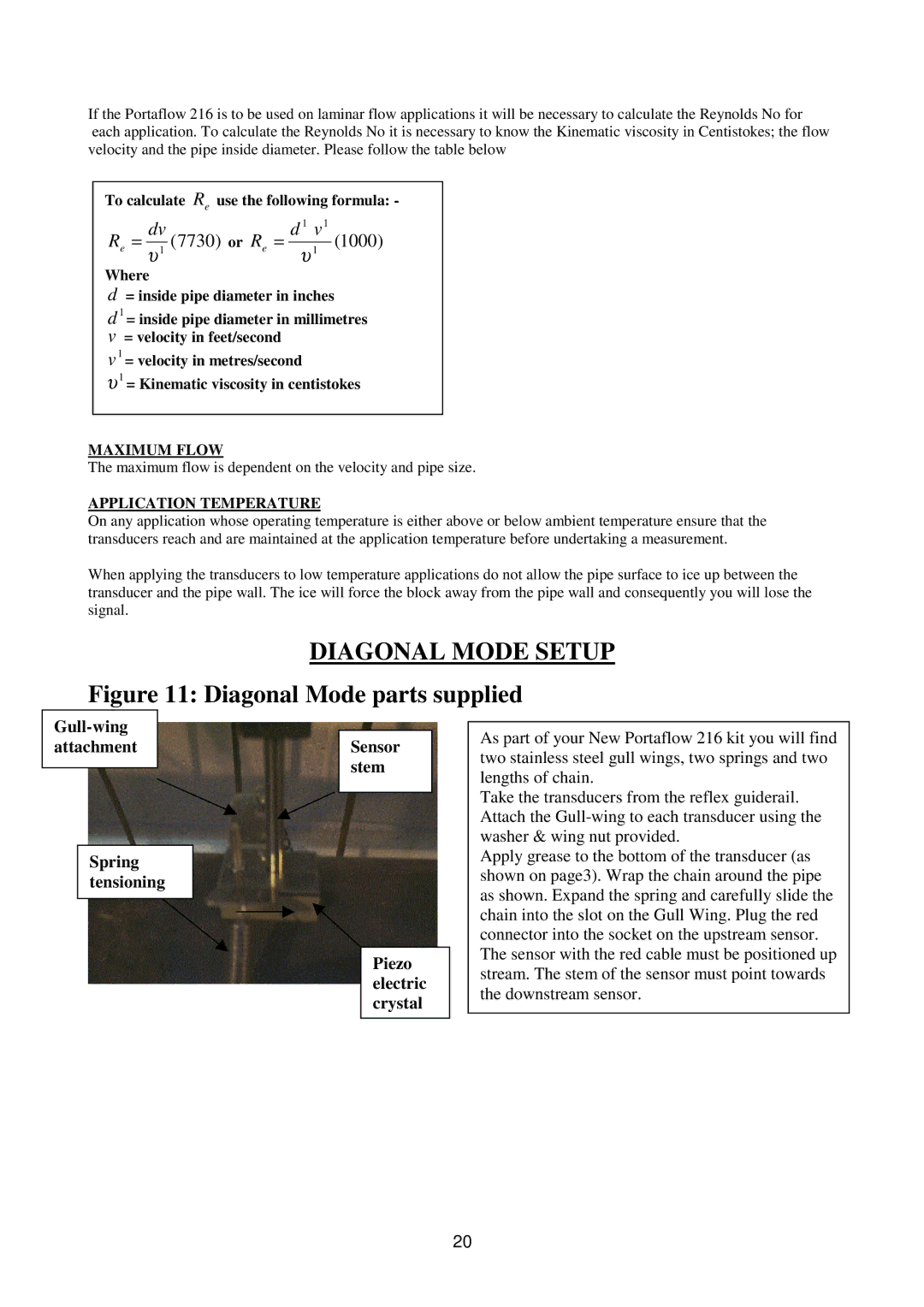

Figure 11: Diagonal Mode parts supplied

Spring tensioning

Sensor stem

Piezo electric crystal

As part of your New Portaflow 216 kit you will find two stainless steel gull wings, two springs and two lengths of chain.

Take the transducers from the reflex guiderail. Attach the

Apply grease to the bottom of the transducer (as shown on page3). Wrap the chain around the pipe as shown. Expand the spring and carefully slide the chain into the slot on the Gull Wing. Plug the red connector into the socket on the upstream sensor. The sensor with the red cable must be positioned up stream. The stem of the sensor must point towards the downstream sensor.

20