Select Quick Start - Press ENTER.

Dimension Units? – Scroll to select units required, press ENTER.

Pipe OD – Enter data, press ENTER.

Pipe Wall Thickness – Enter data, press ENTER.

Pipe Lining Thickness – Enter data, press ENTER. ENTER Zero if there is no lining on the application. Select Wall Material – Select using scroll keys, press ENTER.

Select Lining Material – This will only be displayed if a lining thickness has been entered. Select using the scroll keys, press ENTER.

Select Fluid Type – Select using scroll keys, press ENTER.

The instrument selects the mode of operation using the data entered and will display the following.

Attach sensor set in XXXX mode Approx. max. flow:

XXX m/s

Press ENTER to continue Or SCROLL to change mode

Fluid Temp? Press Enter to Input the application temperature in the units required °C or °F then press ENTER.

Now retract the sensor blocks back into the guide rail by turning the locking nuts clockwise.

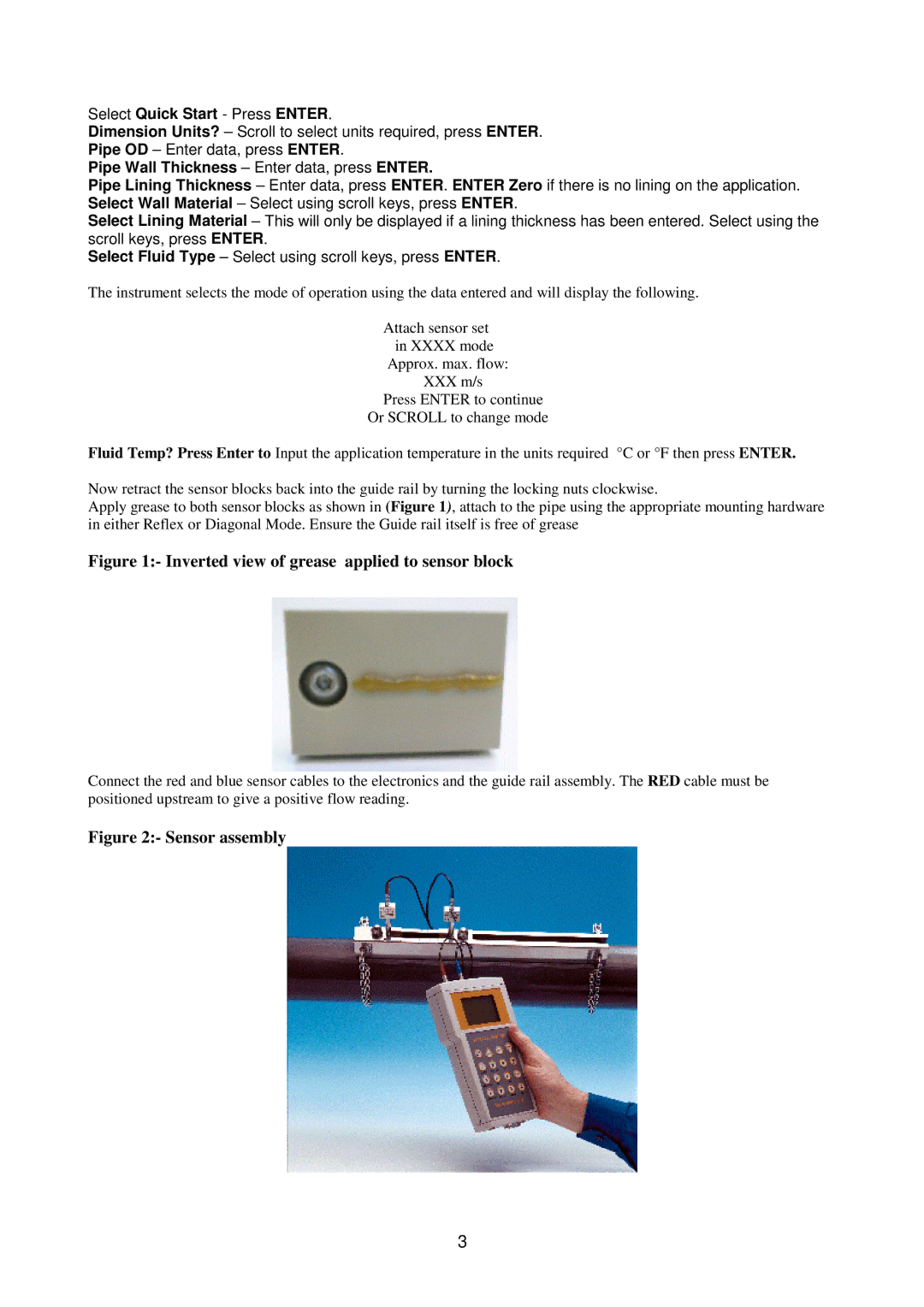

Apply grease to both sensor blocks as shown in (Figure 1), attach to the pipe using the appropriate mounting hardware in either Reflex or Diagonal Mode. Ensure the Guide rail itself is free of grease

Figure 1:- Inverted view of grease applied to sensor block

Connect the red and blue sensor cables to the electronics and the guide rail assembly. The RED cable must be positioned upstream to give a positive flow reading.

Figure 2:- Sensor assembly

3