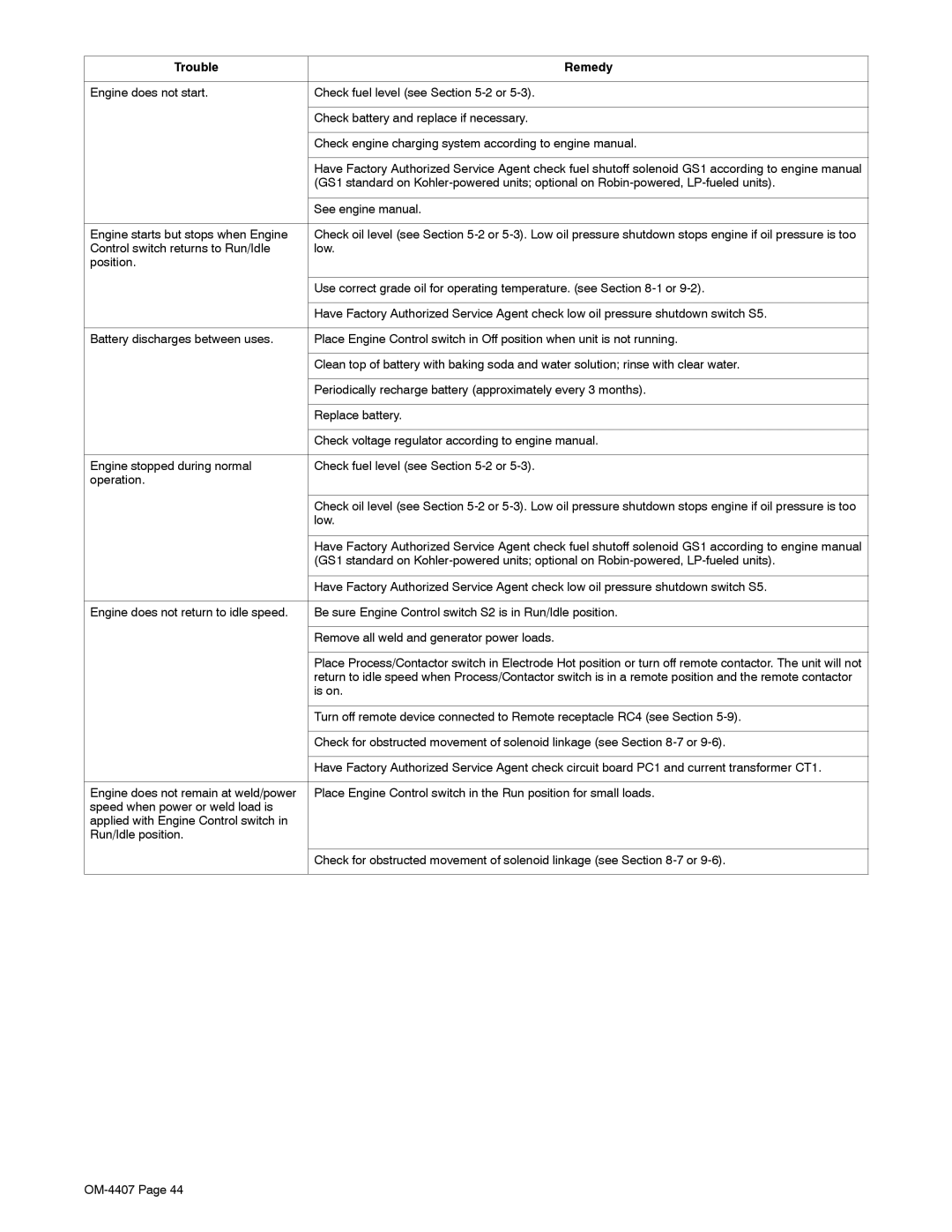

Trouble | Remedy |

|

|

Engine does not start. | Check fuel level (see Section |

|

|

| Check battery and replace if necessary. |

|

|

| Check engine charging system according to engine manual. |

|

|

| Have Factory Authorized Service Agent check fuel shutoff solenoid GS1 according to engine manual |

| (GS1 standard on |

|

|

| See engine manual. |

|

|

Engine starts but stops when Engine | Check oil level (see Section |

Control switch returns to Run/Idle | low. |

position. |

|

|

|

| Use correct grade oil for operating temperature. (see Section |

|

|

| Have Factory Authorized Service Agent check low oil pressure shutdown switch S5. |

|

|

Battery discharges between uses. | Place Engine Control switch in Off position when unit is not running. |

|

|

| Clean top of battery with baking soda and water solution; rinse with clear water. |

|

|

| Periodically recharge battery (approximately every 3 months). |

|

|

| Replace battery. |

|

|

| Check voltage regulator according to engine manual. |

|

|

Engine stopped during normal | Check fuel level (see Section |

operation. |

|

|

|

| Check oil level (see Section |

| low. |

|

|

| Have Factory Authorized Service Agent check fuel shutoff solenoid GS1 according to engine manual |

| (GS1 standard on |

|

|

| Have Factory Authorized Service Agent check low oil pressure shutdown switch S5. |

|

|

Engine does not return to idle speed. | Be sure Engine Control switch S2 is in Run/Idle position. |

|

|

| Remove all weld and generator power loads. |

|

|

| Place Process/Contactor switch in Electrode Hot position or turn off remote contactor. The unit will not |

| return to idle speed when Process/Contactor switch is in a remote position and the remote contactor |

| is on. |

|

|

| Turn off remote device connected to Remote receptacle RC4 (see Section |

|

|

| Check for obstructed movement of solenoid linkage (see Section |

|

|

| Have Factory Authorized Service Agent check circuit board PC1 and current transformer CT1. |

|

|

Engine does not remain at weld/power | Place Engine Control switch in the Run position for small loads. |

speed when power or weld load is |

|

applied with Engine Control switch in |

|

Run/Idle position. |

|

|

|

| Check for obstructed movement of solenoid linkage (see Section |

|

|

Page 48

Image 48