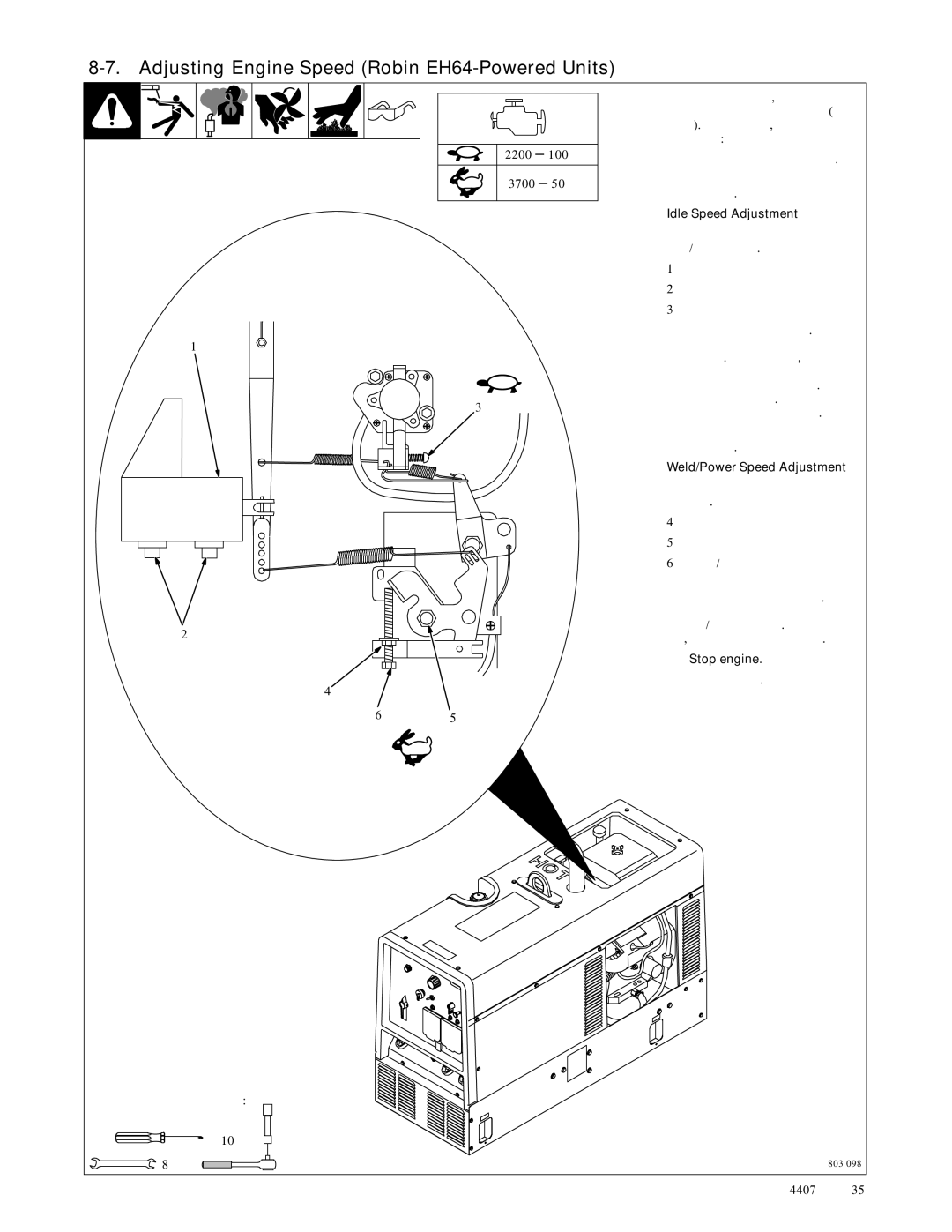

8-7. Adjusting Engine Speed (Robin EH64-Powered Units)

2200 ± 100 rpm

3700 ± 50 rpm

1

3

2

4

65

Tools Needed:

10 mm

![]() 8 mm

8 mm

After tuning engine, check engine speeds with a tachometer (see table). If necessary, adjust speeds as follows:

Start engine and run until warm.

Remove wrapper to access speed adjustments.

Idle Speed Adjustment

Move Engine Control switch to Run/Idle position.

1Throttle Solenoid

2Mounting Screws

3Idle Speed Screw

Loosen mounting screws. Adjust solenoid position so engine runs at idle speed. If necessary, back out idle speed screw so solenoid can be moved to correct position. Tight- en mounting screws. Be sure sole- noid linkage works smoothly.

Turn idle speed screw for fine adjustments.

Weld/Power Speed Adjustment

Move Engine Control switch to Run position.

4Jam Nut

5Lock Nut

6Weld/Power Speed Adjustment Screw

Loosen jam nut and lock nut. Turn adjustment screw until engine runs at weld/power speed. Tighten jam nut, and then tighten lock nut.

YStop engine. Reinstall wrapper.

803 098