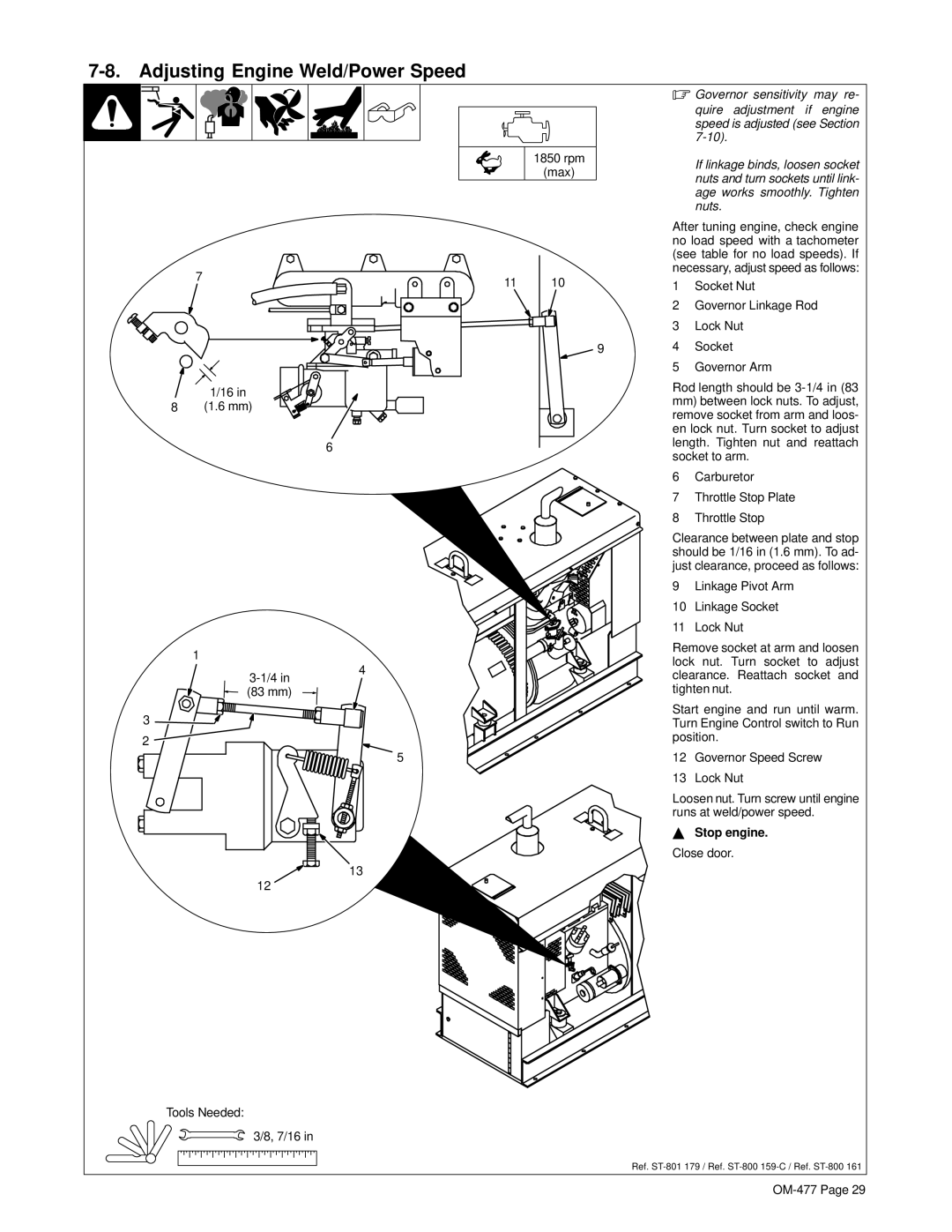

7-8. Adjusting Engine Weld/Power Speed

1850 rpm

(max)

.Governor sensitivity may re- quire adjustment if engine speed is adjusted (see Section

If linkage binds, loosen socket nuts and turn sockets until link- age works smoothly. Tighten nuts.

After tuning engine, check engine no load speed with a tachometer (see table for no load speeds). If necessary, adjust speed as follows:

7

1/16 in

8 (1.6 mm)

6

11 10

![]() 9

9

1Socket Nut

2Governor Linkage Rod

3Lock Nut

4Socket

5Governor Arm

Rod length should be

mm)between lock nuts. To adjust, remove socket from arm and loos- en lock nut. Turn socket to adjust length. Tighten nut and reattach socket to arm.

6Carburetor

7Throttle Stop Plate

8Throttle Stop

Clearance between plate and stop should be 1/16 in (1.6 mm). To ad- just clearance, proceed as follows:

9Linkage Pivot Arm

10Linkage Socket

11Lock Nut

1

4

Remove socket at arm and loosen lock nut. Turn socket to adjust clearance. Reattach socket and

(83 mm)

3 ![]()

![]()

2

5

13

12

Tools Needed:

3/8, 7/16 in

tighten nut.

Start engine and run until warm. Turn Engine Control switch to Run position.

12Governor Speed Screw

13Lock Nut

Loosen nut. Turn screw until engine runs at weld/power speed.

YStop engine.

Close door.

Ref.