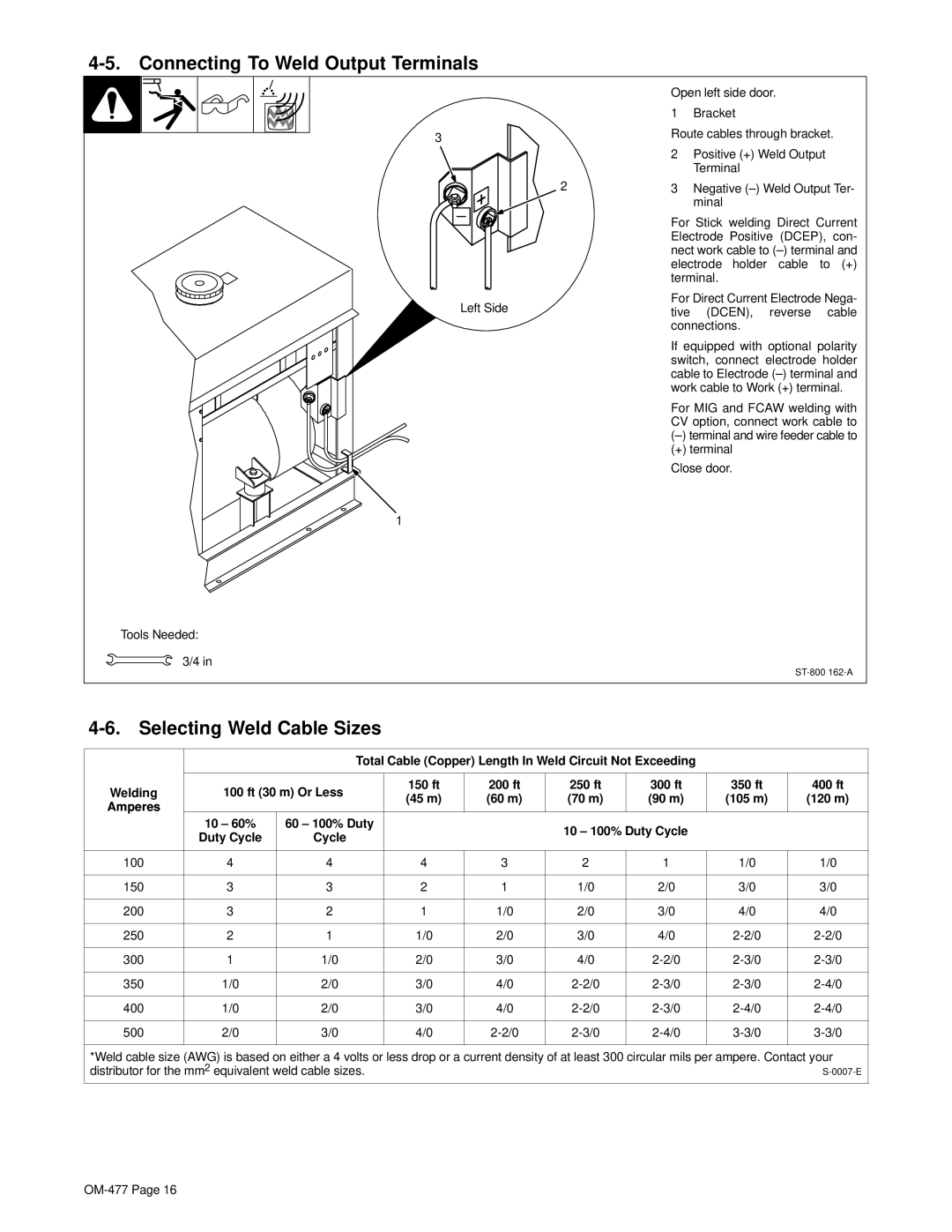

4-5. Connecting To Weld Output Terminals

| Open left side door. | |

| 1 | Bracket |

3 | Route cables through bracket. | |

|

| |

| 2 | Positive (+) Weld Output |

|

| Terminal |

2 | 3 | Negative |

|

| minal |

| For Stick welding Direct Current | |

| Electrode Positive (DCEP), con- | |

| nect work cable to | |

| electrode holder cable to (+) | |

| terminal. | |

For Direct Current Electrode Nega-

Left Sidetive (DCEN), reverse cable connections.

If equipped with optional polarity switch, connect electrode holder cable to Electrode

For MIG and FCAW welding with

CV option, connect work cable to

(+) terminal

Close door.

1

Tools Needed:

3/4 in

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| Total Cable (Copper) Length In Weld Circuit Not Exceeding |

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

Welding | 100 ft (30 m) Or Less | 150 ft | 200 ft | 250 ft | 300 ft | 350 ft | 400 ft |

| |

(45 m) | (60 m) | (70 m) | (90 m) | (105 m) | (120 m) |

| |||

Amperes |

|

|

| ||||||

|

|

|

|

|

|

|

|

| |

| 10 – 60% | 60 – 100% Duty |

|

| 10 – 100% Duty Cycle |

|

|

| |

| Duty Cycle | Cycle |

|

|

|

|

| ||

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

100 | 4 | 4 | 4 | 3 | 2 | 1 | 1/0 | 1/0 |

|

|

|

|

|

|

|

|

|

|

|

150 | 3 | 3 | 2 | 1 | 1/0 | 2/0 | 3/0 | 3/0 |

|

|

|

|

|

|

|

|

|

|

|

200 | 3 | 2 | 1 | 1/0 | 2/0 | 3/0 | 4/0 | 4/0 |

|

|

|

|

|

|

|

|

|

|

|

250 | 2 | 1 | 1/0 | 2/0 | 3/0 | 4/0 |

| ||

|

|

|

|

|

|

|

|

|

|

300 | 1 | 1/0 | 2/0 | 3/0 | 4/0 |

| |||

|

|

|

|

|

|

|

|

|

|

350 | 1/0 | 2/0 | 3/0 | 4/0 |

| ||||

|

|

|

|

|

|

|

|

|

|

400 | 1/0 | 2/0 | 3/0 | 4/0 |

| ||||

|

|

|

|

|

|

|

|

|

|

500 | 2/0 | 3/0 | 4/0 |

| |||||

|

|

|

|

|

|

|

|

|

|

*Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. Contact your

distributor for the mm2 equivalent weld cable sizes. |