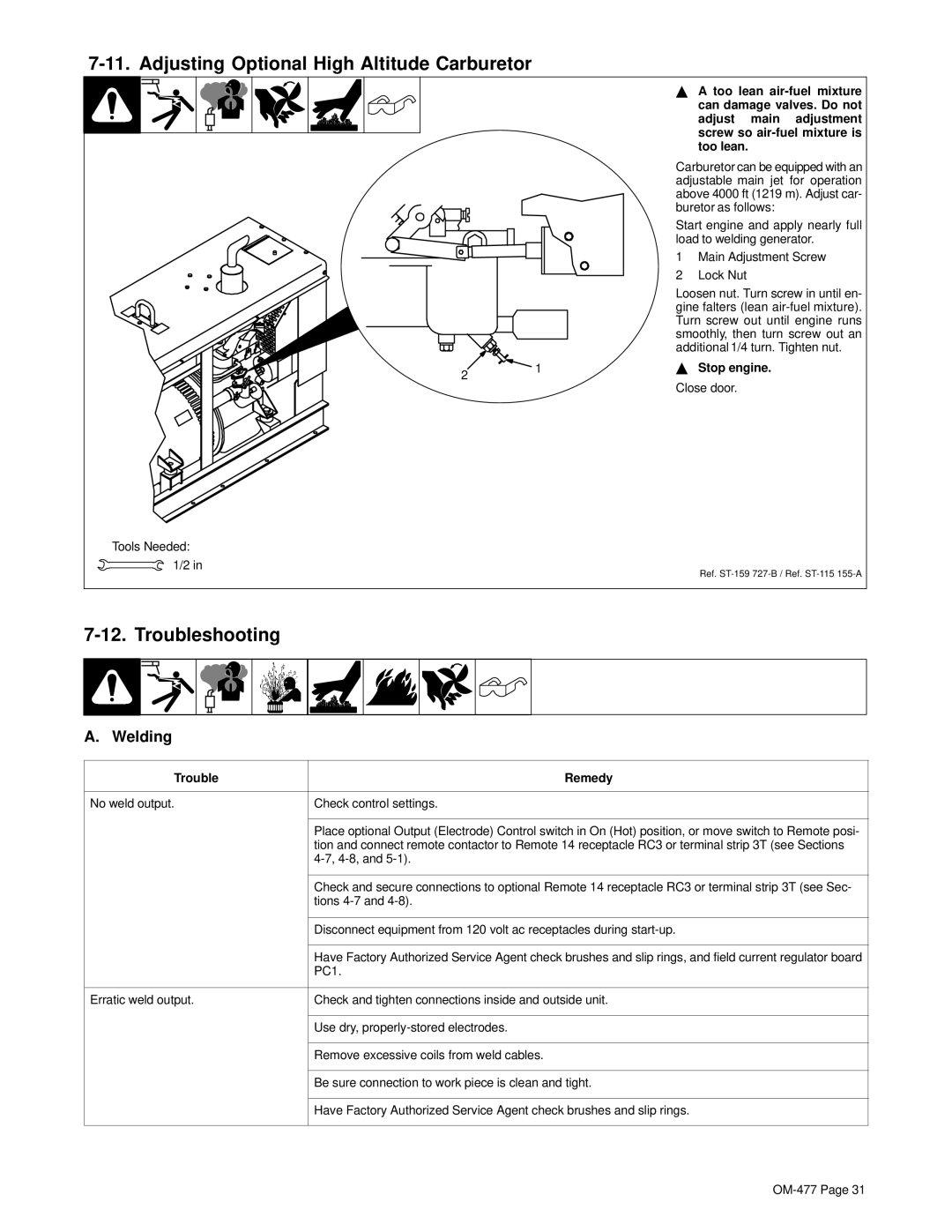

7-11. Adjusting Optional High Altitude Carburetor

Y A too lean

Carburetor can be equipped with an adjustable main jet for operation above 4000 ft (1219 m). Adjust car- buretor as follows:

Start engine and apply nearly full load to welding generator.

1 Main Adjustment Screw

2 Lock Nut

Loosen nut. Turn screw in until en- gine falters (lean

2 | 1 | Y Stop engine. |

|

|

Close door.

Tools Needed:

1/2 in

Ref.

7-12. Troubleshooting

A. Welding

Trouble | Remedy |

|

|

No weld output. | Check control settings. |

|

|

| Place optional Output (Electrode) Control switch in On (Hot) position, or move switch to Remote posi- |

| tion and connect remote contactor to Remote 14 receptacle RC3 or terminal strip 3T (see Sections |

|

|

|

|

| Check and secure connections to optional Remote 14 receptacle RC3 or terminal strip 3T (see Sec- |

| tions |

|

|

| Disconnect equipment from 120 volt ac receptacles during |

|

|

| Have Factory Authorized Service Agent check brushes and slip rings, and field current regulator board |

| PC1. |

|

|

Erratic weld output. | Check and tighten connections inside and outside unit. |

|

|

| Use dry, |

|

|

| Remove excessive coils from weld cables. |

|

|

| Be sure connection to work piece is clean and tight. |

|

|

| Have Factory Authorized Service Agent check brushes and slip rings. |

|

|