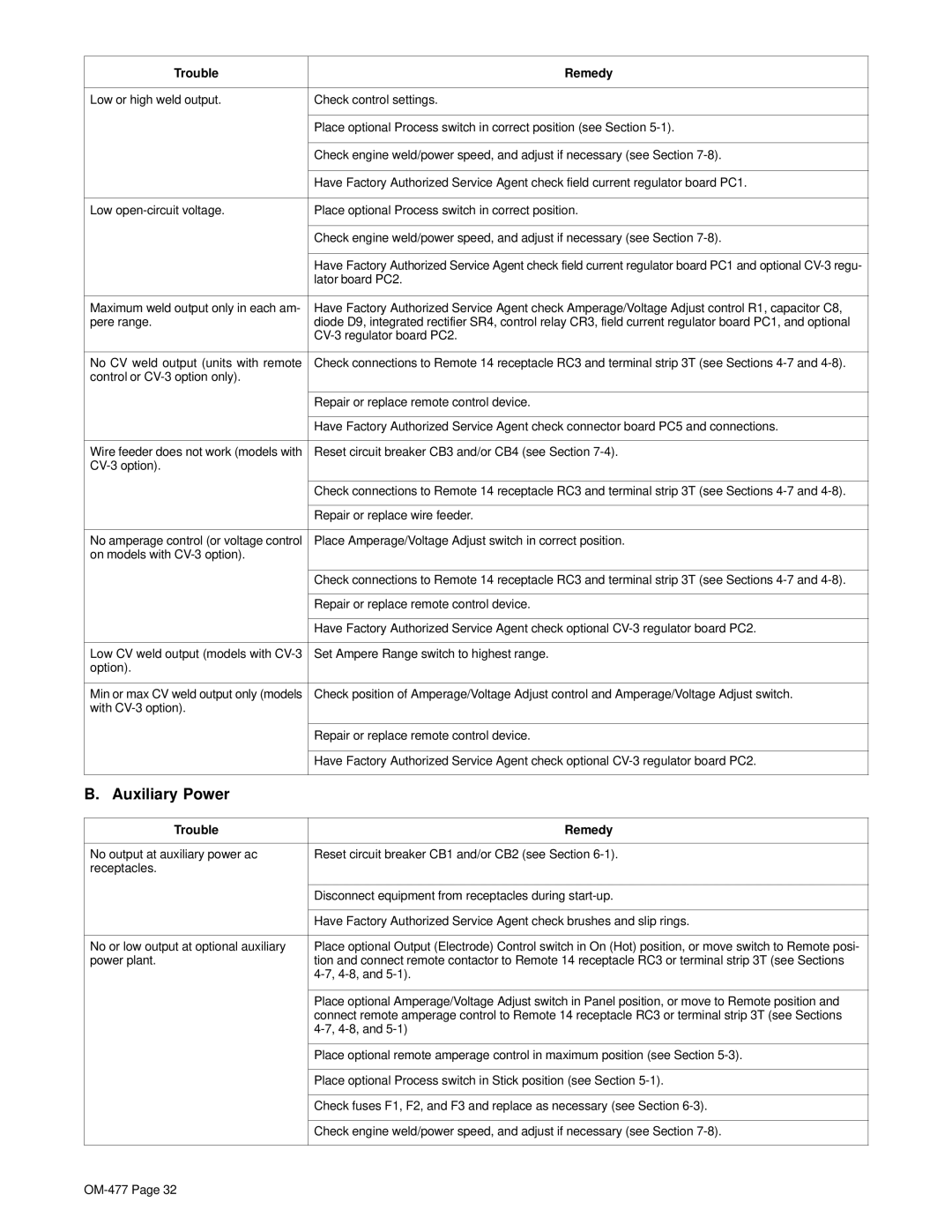

Trouble | Remedy |

|

|

Low or high weld output. | Check control settings. |

|

|

| Place optional Process switch in correct position (see Section |

|

|

| Check engine weld/power speed, and adjust if necessary (see Section |

|

|

| Have Factory Authorized Service Agent check field current regulator board PC1. |

|

|

Low | Place optional Process switch in correct position. |

|

|

| Check engine weld/power speed, and adjust if necessary (see Section |

|

|

| Have Factory Authorized Service Agent check field current regulator board PC1 and optional |

| lator board PC2. |

|

|

Maximum weld output only in each am- | Have Factory Authorized Service Agent check Amperage/Voltage Adjust control R1, capacitor C8, |

pere range. | diode D9, integrated rectifier SR4, control relay CR3, field current regulator board PC1, and optional |

| |

|

|

No CV weld output (units with remote | Check connections to Remote 14 receptacle RC3 and terminal strip 3T (see Sections |

control or |

|

|

|

| Repair or replace remote control device. |

|

|

| Have Factory Authorized Service Agent check connector board PC5 and connections. |

|

|

Wire feeder does not work (models with | Reset circuit breaker CB3 and/or CB4 (see Section |

| |

|

|

| Check connections to Remote 14 receptacle RC3 and terminal strip 3T (see Sections |

|

|

| Repair or replace wire feeder. |

|

|

No amperage control (or voltage control | Place Amperage/Voltage Adjust switch in correct position. |

on models with |

|

|

|

| Check connections to Remote 14 receptacle RC3 and terminal strip 3T (see Sections |

|

|

| Repair or replace remote control device. |

|

|

| Have Factory Authorized Service Agent check optional |

|

|

Low CV weld output (models with | Set Ampere Range switch to highest range. |

option). |

|

|

|

Min or max CV weld output only (models | Check position of Amperage/Voltage Adjust control and Amperage/Voltage Adjust switch. |

with |

|

|

|

| Repair or replace remote control device. |

|

|

| Have Factory Authorized Service Agent check optional |

|

|

B. Auxiliary Power |

|

Trouble | Remedy |

|

|

No output at auxiliary power ac | Reset circuit breaker CB1 and/or CB2 (see Section |

receptacles. |

|

|

|

| Disconnect equipment from receptacles during |

|

|

| Have Factory Authorized Service Agent check brushes and slip rings. |

|

|

No or low output at optional auxiliary | Place optional Output (Electrode) Control switch in On (Hot) position, or move switch to Remote posi- |

power plant. | tion and connect remote contactor to Remote 14 receptacle RC3 or terminal strip 3T (see Sections |

|

|

|

|

| Place optional Amperage/Voltage Adjust switch in Panel position, or move to Remote position and |

| connect remote amperage control to Remote 14 receptacle RC3 or terminal strip 3T (see Sections |

| |

|

|

| Place optional remote amperage control in maximum position (see Section |

|

|

| Place optional Process switch in Stick position (see Section |

|

|

| Check fuses F1, F2, and F3 and replace as necessary (see Section |

|

|

| Check engine weld/power speed, and adjust if necessary (see Section |

|

|