. A complete Parts List is available at www.MillerWelds.com

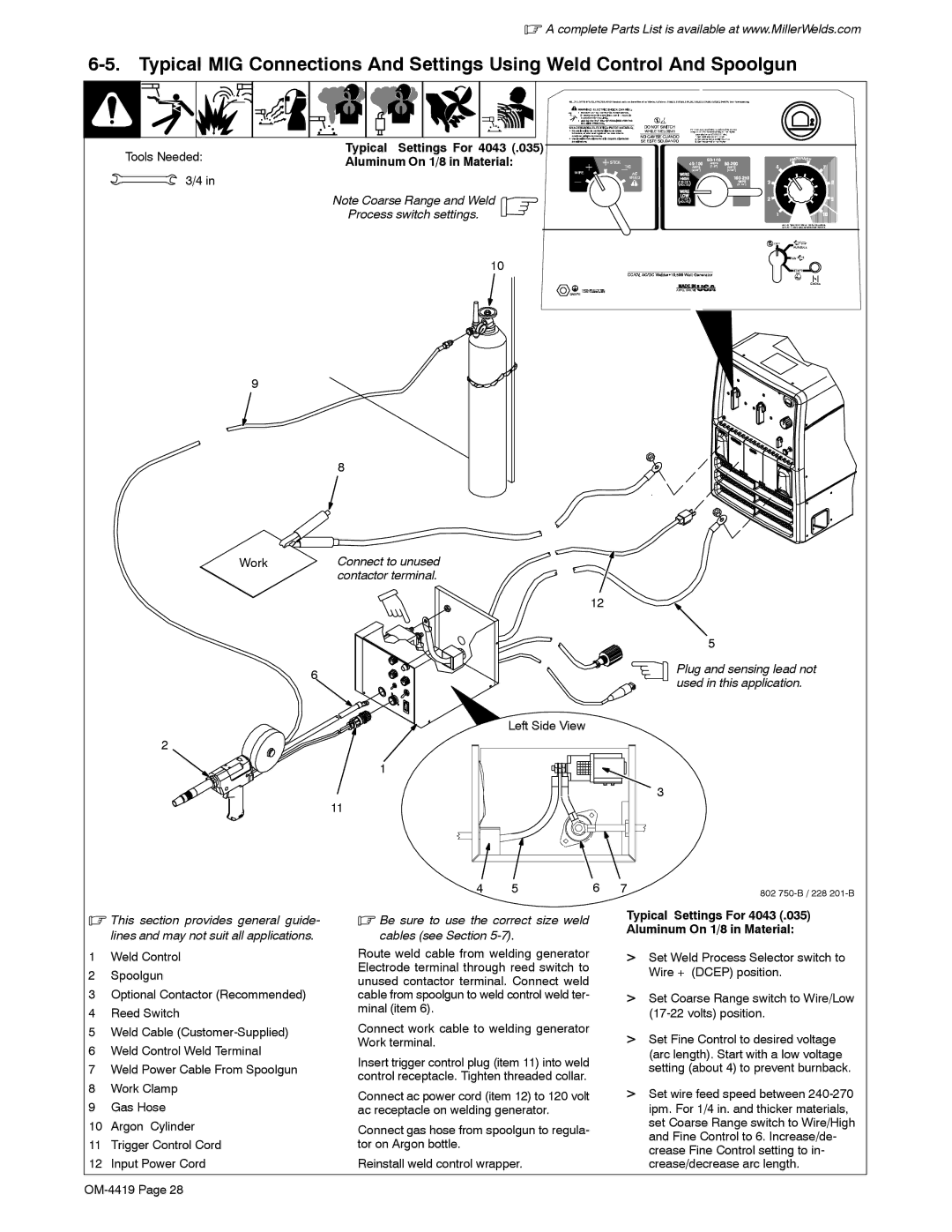

Tools Needed: | Typical Settings For 4043 (.035) | |

Aluminum On 1/8 in Material: | ||

| ||

3/4 in |

| |

| Note Coarse Range and Weld | |

| Process switch settings. | |

| 10 |

9

8

Work | Connect to unused |

| contactor terminal. |

12

6

5

Plug and sensing lead not used in this application.

Left Side View

2

1

3

11

|

| 4 | 5 | 6 | 7 | 802 |

|

|

|

|

|

| |

. This section provides general guide- | . Be sure to use the correct size weld |

| Typical Settings For 4043 (.035) | |||

| lines and may not suit all applications. | cables (see Section |

| Aluminum On 1/8 in Material: | ||

|

|

|

| |||

1 | Weld Control | Route weld cable from welding generator |

| > Set Weld Process Selector switch to | ||

2 | Spoolgun | Electrode terminal through reed switch to |

|

| Wire + (DCEP) position. | |

unused contactor terminal. Connect weld |

|

| ||||

|

|

|

|

| ||

3 | Optional Contactor (Recommended) | cable from spoolgun to weld control weld ter- |

| > Set Coarse Range switch to Wire/Low | ||

4 | Reed Switch | minal (item 6). |

|

|

| |

|

|

|

| |||

5 | Weld Cable | Connect work cable to welding generator |

| > Set Fine Control to desired voltage | ||

6 | Weld Control Weld Terminal | Work terminal. |

|

| ||

Insert trigger control plug (item 11) into weld |

|

| (arc length). Start with a low voltage | |||

7 | Weld Power Cable From Spoolgun |

|

| setting (about 4) to prevent burnback. | ||

control receptacle. Tighten threaded collar. |

|

| ||||

8 | Work Clamp |

|

|

| ||

Connect ac power cord (item 12) to 120 volt |

| > Set wire feed speed between | ||||

9 | Gas Hose |

| ||||

ac receptacle on welding generator. |

|

| ipm. For 1/4 in. and thicker materials, | |||

10 | Argon Cylinder | Connect gas hose from spoolgun to regula- |

|

| set Coarse Range switch to Wire/High | |

11 | Trigger Control Cord | tor on Argon bottle. |

|

|

| and Fine Control to 6. Increase/de- |

|

|

| crease Fine Control setting to in- | |||

|

|

|

|

|

| |

12 | Input Power Cord | Reinstall weld control wrapper. |

|

| crease/decrease arc length. | |