. A complete Parts List is available at www.MillerWelds.com

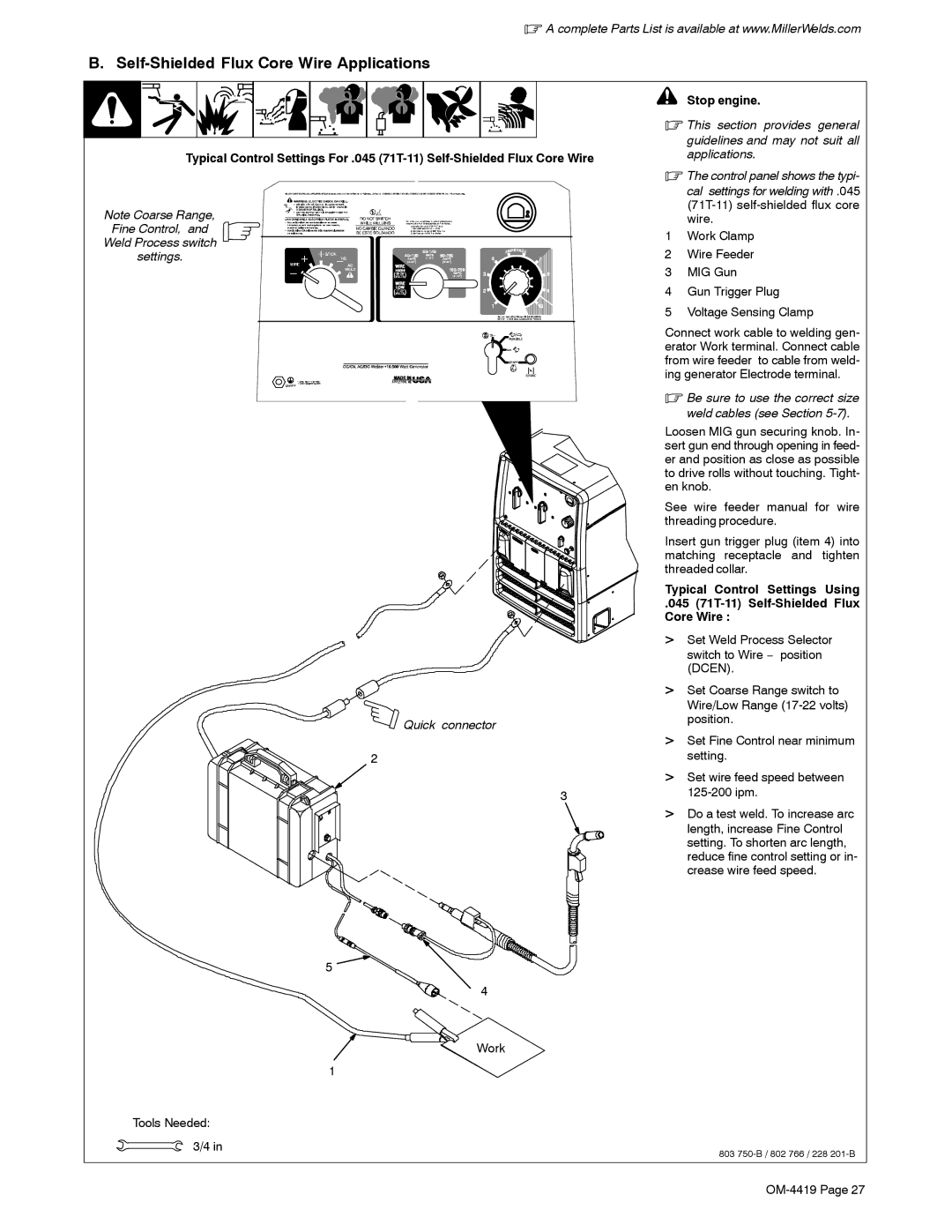

B. Self-Shielded Flux Core Wire Applications

Typical Control Settings For .045

Note Coarse Range,

Fine Control, and

Weld Process switch

settings.

! Stop engine.

.This section provides general

guidelines and may not suit all applications.

.The control panel shows the typi-

cal settings for welding with .045

1Work Clamp

2Wire Feeder

3MIG Gun

4Gun Trigger Plug

5Voltage Sensing Clamp

Connect work cable to welding gen- erator Work terminal. Connect cable from wire feeder to cable from weld- ing generator Electrode terminal.

.Be sure to use the correct size weld cables (see Section 5-7).

Loosen MIG gun securing knob. In- sert gun end through opening in feed- er and position as close as possible to drive rolls without touching. Tight- en knob.

See wire feeder manual for wire threading procedure.

Insert gun trigger plug (item 4) into matching receptacle and tighten threaded collar.

Typical Control Settings Using

.045

Core Wire :

> Set Weld Process Selector

| switch to Wire − position |

| (DCEN). |

| > Set Coarse Range switch to |

| Wire/Low Range |

Quick connector | position. |

| |

| > Set Fine Control near minimum |

2 | setting. |

| > Set wire feed speed between |

3 | |

| > Do a test weld. To increase arc |

| length, increase Fine Control |

| setting. To shorten arc length, |

| reduce fine control setting or in- |

| crease wire feed speed. |

| 5 |

| 4 |

| Work |

| 1 |

Tools Needed: |

|

3/4 in | 803 |

|