. A complete Parts List is available at www.MillerWelds.com

SECTION 6 − OPERATING THE WELDING GENERATOR

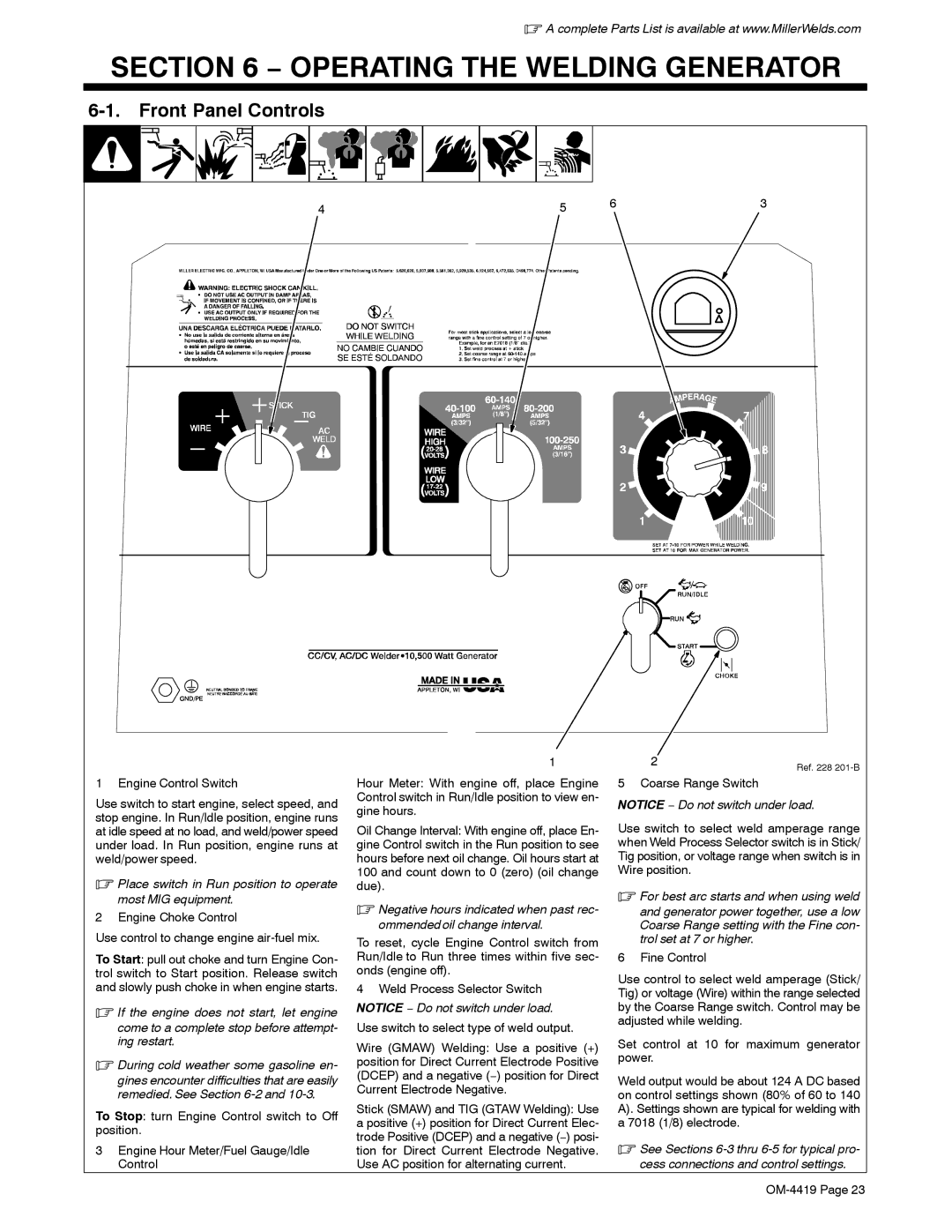

6-1. Front Panel Controls

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 6 | 3 | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

4 |

|

|

| 5 | |||||||||||||||||||||||||||

|

|

|

|

|

|

|

| ||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 |

| 2 | Ref. 228 | |

|

|

|

|

| ||

1 | Engine Control Switch | Hour Meter: With engine off, place Engine | 5 | Coarse Range Switch |

| |

Use switch to start engine, select speed, and | Control switch in Run/Idle position to view en- | NOTICE − Do not switch under load. | ||||

gine hours. | ||||||

stop engine. In Run/Idle position, engine runs |

|

|

| |||

Oil Change Interval: With engine off, place En- | Use switch to select weld amperage range | |||||

at idle speed at no load, and weld/power speed | ||||||

under load. In Run position, engine runs at | gine Control switch in the Run position to see | when Weld Process Selector switch is in Stick/ | ||||

weld/power speed. | hours before next oil change. Oil hours start at | Tig position, or voltage range when switch is in | ||||

. Place switch in Run position to operate | 100 and count down to 0 (zero) (oil change | Wire position. |

| |||

due). | . For best arc starts and when using weld | |||||

| most MIG equipment. | . Negative hours indicated when past rec- | ||||

2 | Engine Choke Control |

| and generator power together, use a low | |||

ommended oil change interval. |

| Coarse Range setting with the Fine con- | ||||

Use control to change engine |

| |||||

To reset, cycle Engine Control switch from |

| trol set at 7 or higher. |

| |||

To Start: pull out choke and turn Engine Con- | Run/Idle to Run three times within five sec- | 6 | Fine Control |

| ||

trol switch to Start position. Release switch | onds (engine off). | Use control to select weld amperage (Stick/ | ||||

and slowly push choke in when engine starts. | 4 Weld Process Selector Switch | |||||

Tig) or voltage (Wire) within the range selected | ||||||

. If the engine does not start, let engine | NOTICE − Do not switch under load. | by the Coarse Range switch. Control may be | ||||

| come to a complete stop before attempt- | Use switch to select type of weld output. | adjusted while welding. |

| ||

|

|

|

| |||

| ing restart. | Wire (GMAW) Welding: Use a positive (+) | Set control at 10 for maximum generator | |||

. During cold weather some gasoline en- | position for Direct Current Electrode Positive | power. |

| |||

| gines encounter difficulties that are easily | (DCEP) and a negative (−) position for Direct | Weld output would be about 124 A DC based | |||

| Current Electrode Negative. | |||||

| remedied. See Section | on control settings shown (80% of 60 to 140 | ||||

|

| |||||

To Stop: turn Engine Control switch to Off | Stick (SMAW) and TIG (GTAW Welding): Use | A). Settings shown are typical for welding with | ||||

a positive (+) position for Direct Current Elec- | a 7018 (1/8) electrode. |

| ||||

position. |

| |||||

trode Positive (DCEP) and a negative (−) posi- |

|

|

| |||

|

| . See Sections | ||||

3 | Engine Hour Meter/Fuel Gauge/Idle | tion for Direct Current Electrode Negative. | ||||

| Control | Use AC position for alternating current. |

| cess connections and control settings. | ||