SECTION 15 − MIG WELDING (GMAW) GUIDELINES

| Gun |

Workpiece | |

Work Clamp | Voltage |

Sensing Clamp

| ! Weld current can damage | ||||

| electronic parts in vehicles. | ||||

| Disconnect | both | battery | ||

| cables before welding on a | ||||

Constant | vehicle. Place work clamp as | ||||

close to the weld as possible. | |||||

Current (CC) | Voltage sensing wire feeders are | ||||

Or Constant | |||||

used with constant current (CC) or | |||||

Voltage (CV) | |||||

constant | voltage | (CV) | power | ||

Power Source | |||||

sources (14 pin receptacle not re- | |||||

| |||||

| quired). |

|

|

| |

| If using a CC or CV welding power | ||||

| source without a weld output con- | ||||

| tactor, use optional secondary con- | ||||

| tactor. |

|

|

| |

| For GMAW, use optional gas valve. | ||||

Voltage |

|

Sensing Wire |

|

Feeder | Electrode Lead |

| |

| Work Lead |

802 488

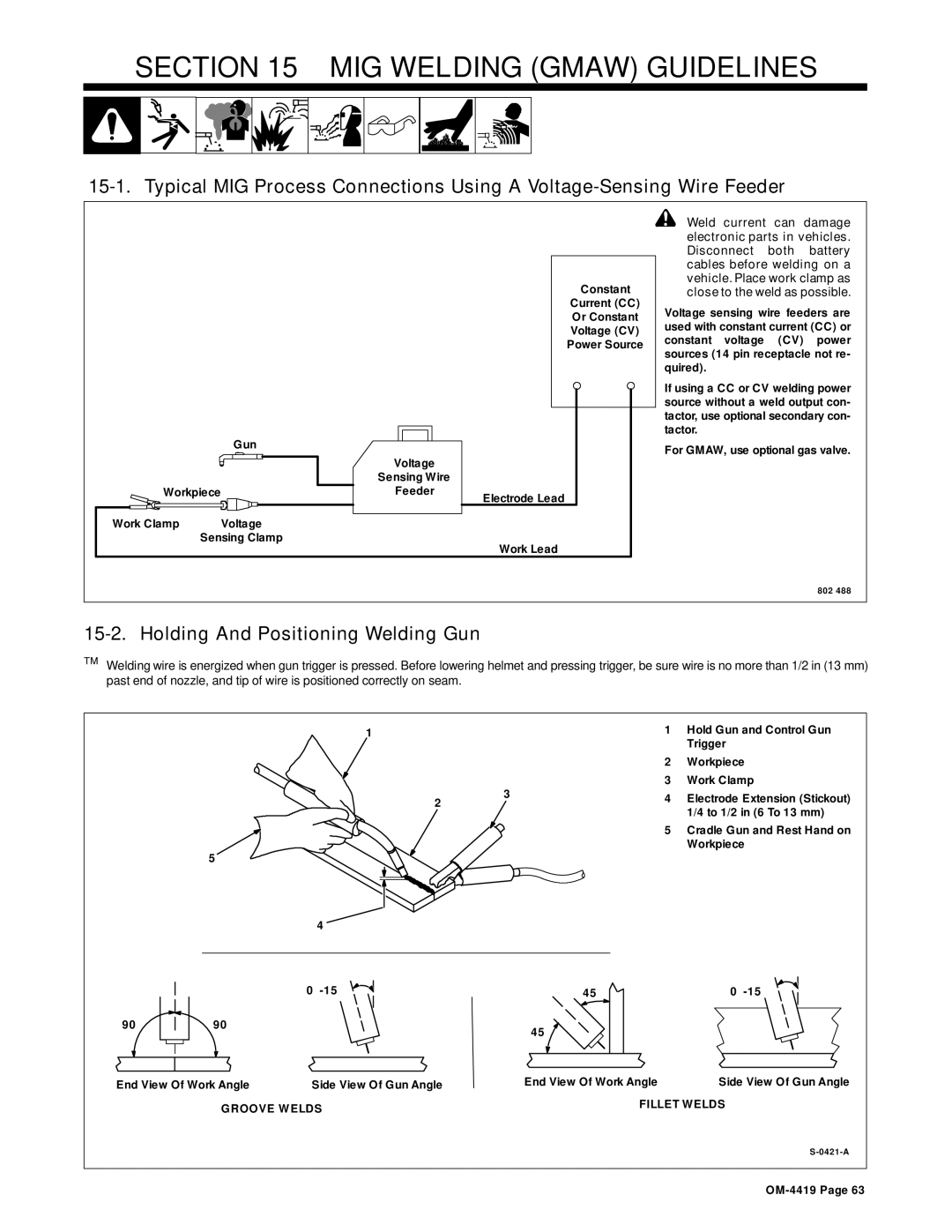

15-2. Holding And Positioning Welding Gun

.Welding wire is energized when gun trigger is pressed. Before lowering helmet and pressing trigger, be sure wire is no more than 1/2 in (13 mm) past end of nozzle, and tip of wire is positioned correctly on seam.

|

| 1 |

| 1 | Hold Gun and Control Gun |

|

|

|

|

| Trigger |

|

|

|

| 2 | Workpiece |

|

|

| 3 | 3 | Work Clamp |

|

| 2 | 4 | Electrode Extension (Stickout) | |

|

|

| |||

|

|

|

| 1/4 to 1/2 in (6 To 13 mm) | |

|

|

|

|

| |

|

|

|

| 5 Cradle Gun and Rest Hand on | |

| 5 |

|

|

| Workpiece |

|

|

|

|

| |

|

| 4 |

|

|

|

|

|

| ° | ° ° | |

|

|

|

| 45 | 0 |

90° | 90° |

|

| 45° |

|

|

|

|

|

| |

End View Of Work Angle | Side View Of Gun Angle |

| End View Of Work Angle | Side View Of Gun Angle | |

| GROOVE WELDS |

| FILLET WELDS | ||

|

|

|

| ||

|

|

|

|

| |