SECTION 13 − GENERATOR POWER GUIDELINES

.The views in this section are intended to be representative of all

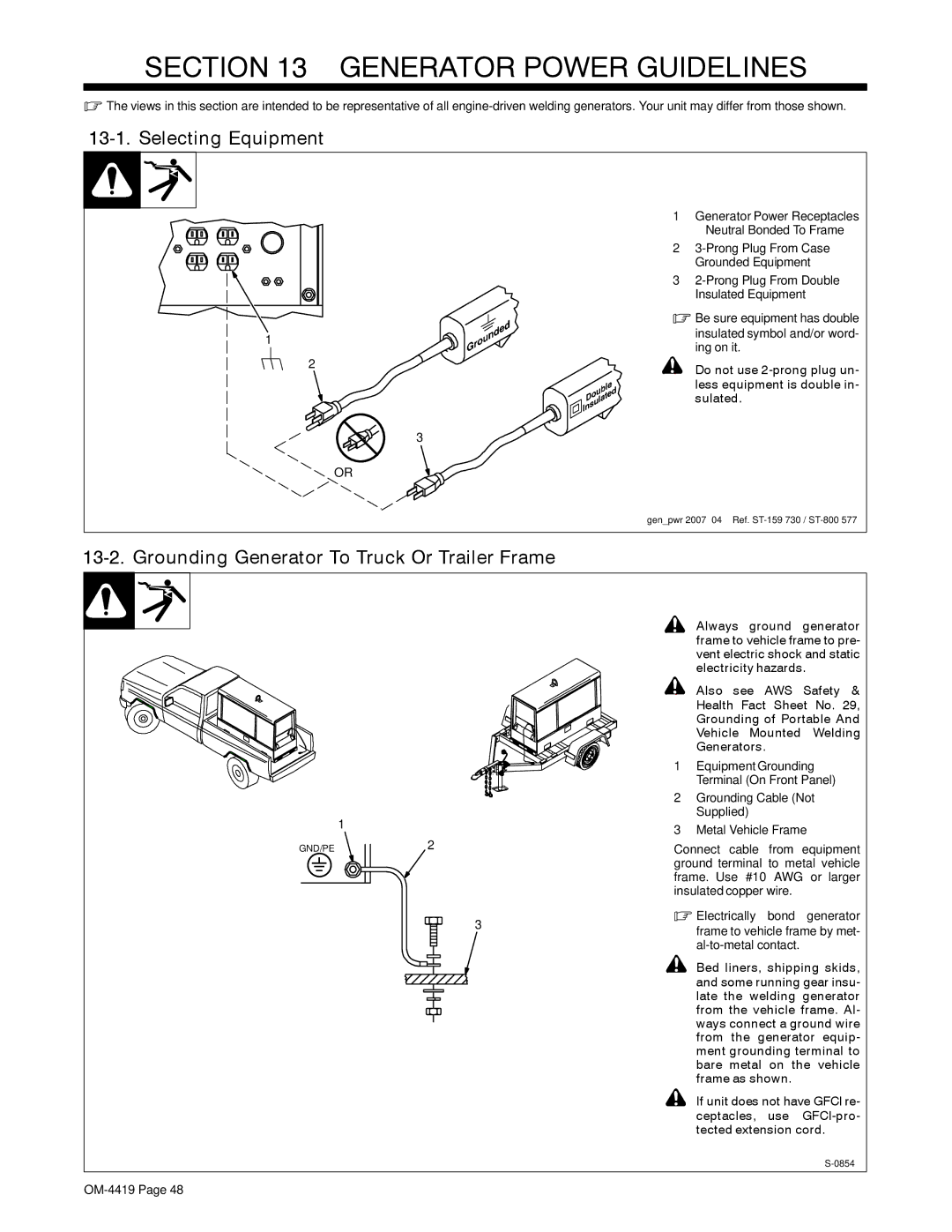

13-1. Selecting Equipment

1

2

3

OR

1Generator Power Receptacles − Neutral Bonded To Frame

2

3

.Be sure equipment has double

insulated symbol and/or word- ing on it.

![]() ! Do not use

! Do not use

gen_pwr 2007−04 − Ref.

13-2. Grounding Generator To Truck Or Trailer Frame

! Always ground generator frame to vehicle frame to pre- vent electric shock and static electricity hazards.

! Also see AWS Safety & Health Fact Sheet No. 29, Grounding of Portable And Vehicle Mounted Welding Generators.

|

|

| 1 | Equipment Grounding | ||

|

|

|

| Terminal (On Front Panel) | ||

|

|

| 2 | Grounding Cable (Not | ||

| 1 |

|

| Supplied) |

|

|

|

| 3 | Metal Vehicle Frame | |||

|

|

| ||||

GND/PE | 2 |

| Connect cable | from | equipment | |

|

|

| ground terminal to metal vehicle | |||

|

|

| frame. Use #10 AWG or larger | |||

|

|

| insulated copper wire. |

| ||

|

| 3 | . Electrically | bond | generator | |

|

|

| frame to vehicle frame by met- | |||

|

|

|

| |||

al-to-metal contact.

! Bed liners, shipping skids, and some running gear insu- late the welding generator from the vehicle frame. Al- ways connect a ground wire from the generator equip- ment grounding terminal to bare metal on the vehicle frame as shown.

! If unit does not have GFCI re- ceptacles, use