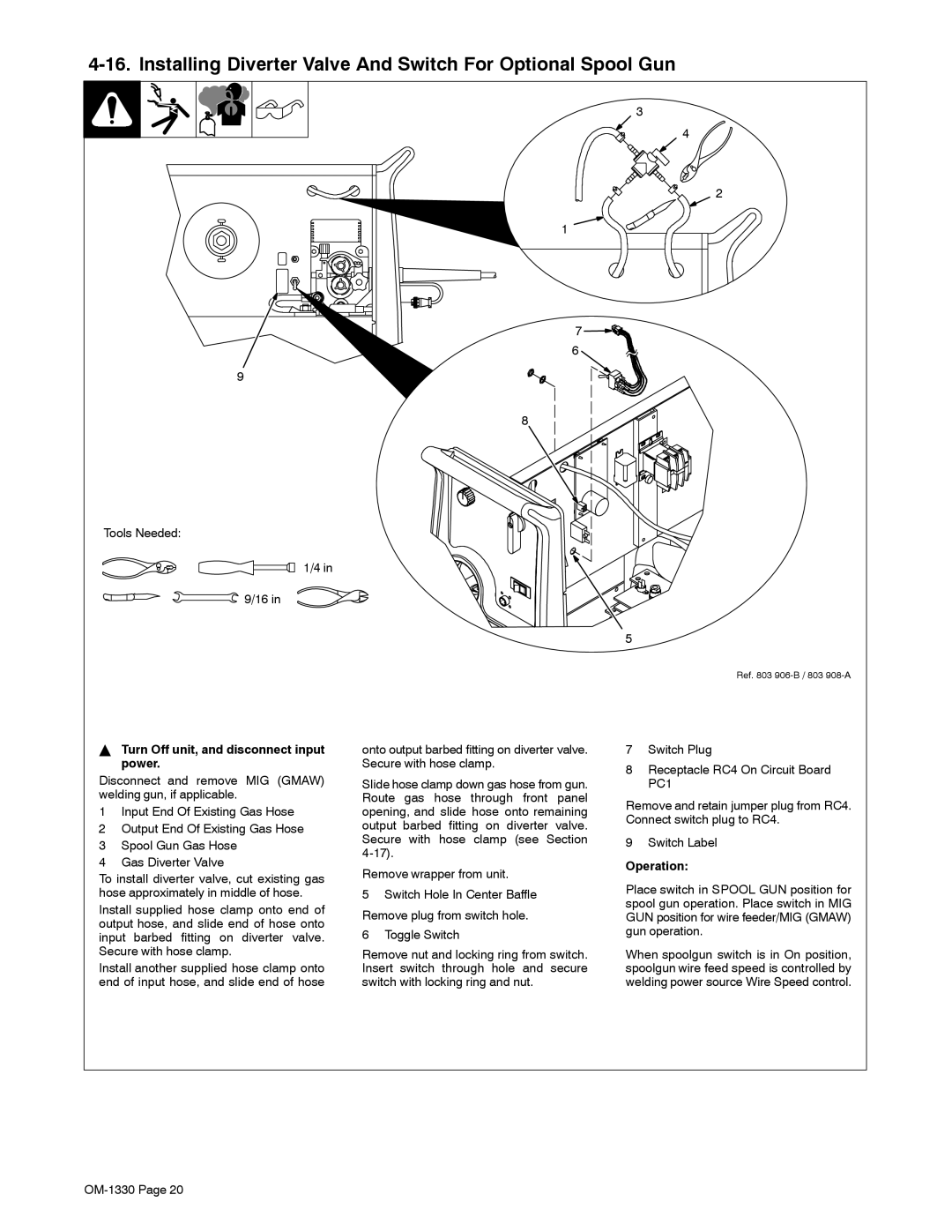

4-16. Installing Diverter Valve And Switch For Optional Spool Gun

3

4

2

1

7 ![]()

6

9

8

Tools Needed:

1/4 in

9/16 in

5

Ref. 803

YTurn Off unit, and disconnect input power.

Disconnect and remove MIG (GMAW) welding gun, if applicable.

1Input End Of Existing Gas Hose

2Output End Of Existing Gas Hose

3Spool Gun Gas Hose

4Gas Diverter Valve

To install diverter valve, cut existing gas hose approximately in middle of hose.

Install supplied hose clamp onto end of output hose, and slide end of hose onto input barbed fitting on diverter valve. Secure with hose clamp.

Install another supplied hose clamp onto end of input hose, and slide end of hose

onto output barbed fitting on diverter valve. Secure with hose clamp.

Slide hose clamp down gas hose from gun. Route gas hose through front panel opening, and slide hose onto remaining output barbed fitting on diverter valve. Secure with hose clamp (see Section

Remove wrapper from unit.

5Switch Hole In Center Baffle Remove plug from switch hole.

6Toggle Switch

Remove nut and locking ring from switch. Insert switch through hole and secure switch with locking ring and nut.

7Switch Plug

8Receptacle RC4 On Circuit Board PC1

Remove and retain jumper plug from RC4. Connect switch plug to RC4.

9Switch Label

Operation:

Place switch in SPOOL GUN position for spool gun operation. Place switch in MIG GUN position for wire feeder/MIG (GMAW) gun operation.

When spoolgun switch is in On position, spoolgun wire feed speed is controlled by welding power source Wire Speed control.