.This unit has a max OCV control circuit

that resets Amperage/Voltage Control R1 to maximum when the arc breaks. When an arc is struck, weld output con- trol returns to the R1 front panel or com- bination front panel/remote control setting. The Amperage/Voltage control adjusts amperage only when constant current (CC) welding and does not ad- just

1 Ampere Range Switch

YDo not switch under load.

Use switch to select one of five ampere ranges. Use the lower four ranges for CC welding. Use the highest range for CV/DC welding.

For most welding applications, use lowest amperage range possible to help prevent arc outages.

2 Amperage/Voltage Control

With CC/CV switch in CC position, use con- trol to adjust amperage within range selected by Ampere Ranges switch. With switch in CV position, use control to adjust voltage.

Weld output would be 223 A DC with amperage controls set as shown (50% of 125 to 320 A).

3Manual Stop Control

4Engine Start Button

5Ether Starting Aid Switch (Optional)

Push switch up and release while cranking engine to release ether.

YDo not use Ether if engine is running.

To Start: Press button and use Ether switch (if necessary). Release button when engine starts.

Do not crank engine while engine is turning.

To Stop: Pull control out and hold. Release control when engine stops.

6DC Ammeter (Optional)

7DC Voltmeter (Optional)

8Oil Pressure Warning Light

Light goes off if oil pressure is too low.

YIf light goes off, stop engine and check oil level.

9 Battery Charging Warning Light

Light goes on when battery is not charging.

YIf light goes on, stop engine and check engine belt.

10Engine Hour Meter

11Polarity Switch (Optional)

12Constant Current/Constant Voltage (CC/CV) Switch

Use switch to select type of weld output. Use

CCfor Stick (SMAW) welding. Use CV for wire feed processes (MIG, FCAW). If using CV, place Ampere Range switch in maxi- mum position.

13 Output/Contactor Switch

YWeld output terminals are energized when Output/Contactor switch is On and engine is running

Use switch to control remote contactor con- nected to Remote 14 receptacle RC3 or ter- minal strip 2T.

For weld output, place switch in the On posi- tion.

For remote output control, place switch in Remote position.

14 Amperage/Voltage Control Switch

Use switch to select front panel or remote amperage and voltage adjustment.

For front panel control, place switch in Panel position. For remote control, place switch in Remote position and connect remote control to Remote 14 receptacle RC3 or terminal strip 2T.

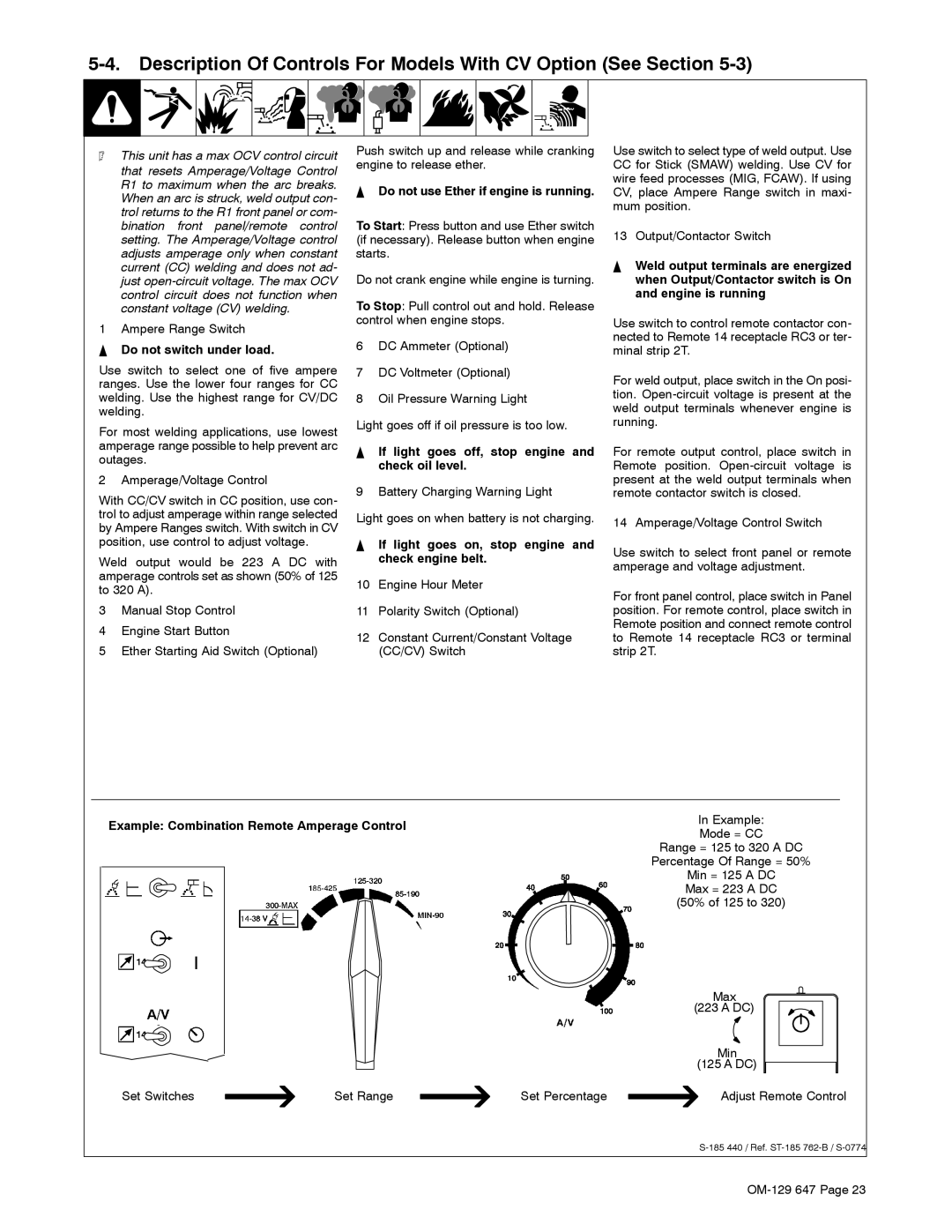

Example: Combination Remote Amperage Control | In Example: | |

Mode = CC | ||

| ||

| Range = 125 to 320 A DC | |

| Percentage Of Range = 50% | |

| Min = 125 A DC | |

| Max = 223 A DC | |

| (50% of 125 to 320) |

Max

(223 A DC)

Min

(125 A DC)

Set Switches | Set Range | Set Percentage | Adjust Remote Control |