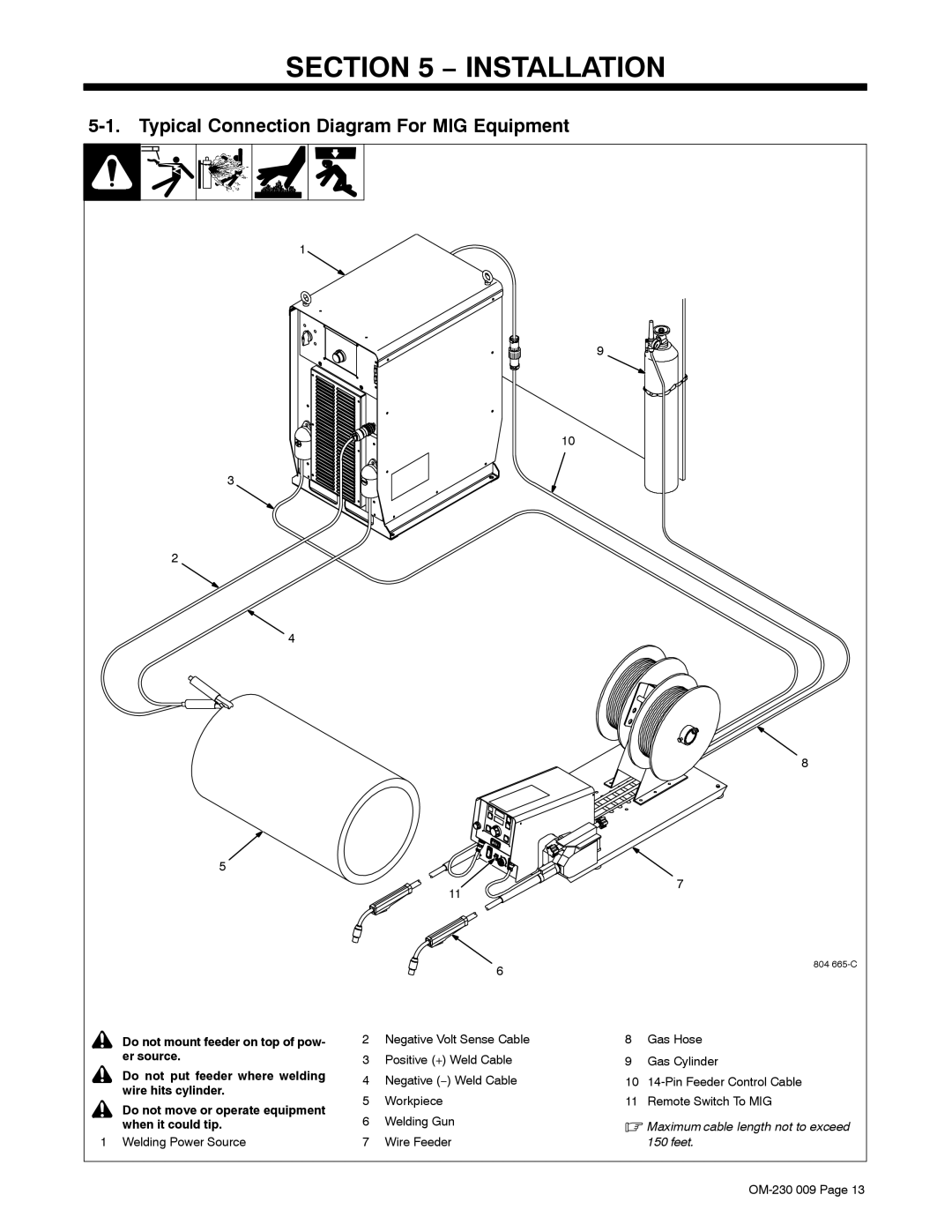

SECTION 5 − INSTALLATION

5-1. Typical Connection Diagram For MIG Equipment

1

9

10

3

2

4

5

11

6

8

7

804

!Do not mount feeder on top of pow- er source.

!Do not put feeder where welding wire hits cylinder.

!Do not move or operate equipment when it could tip.

1 Welding Power Source

2Negative Volt Sense Cable

3Positive (+) Weld Cable

4Negative (−) Weld Cable

5Workpiece

6Welding Gun

7Wire Feeder

8Gas Hose

9Gas Cylinder

10

11Remote Switch To MIG

.Maximum cable length not to exceed 150 feet.