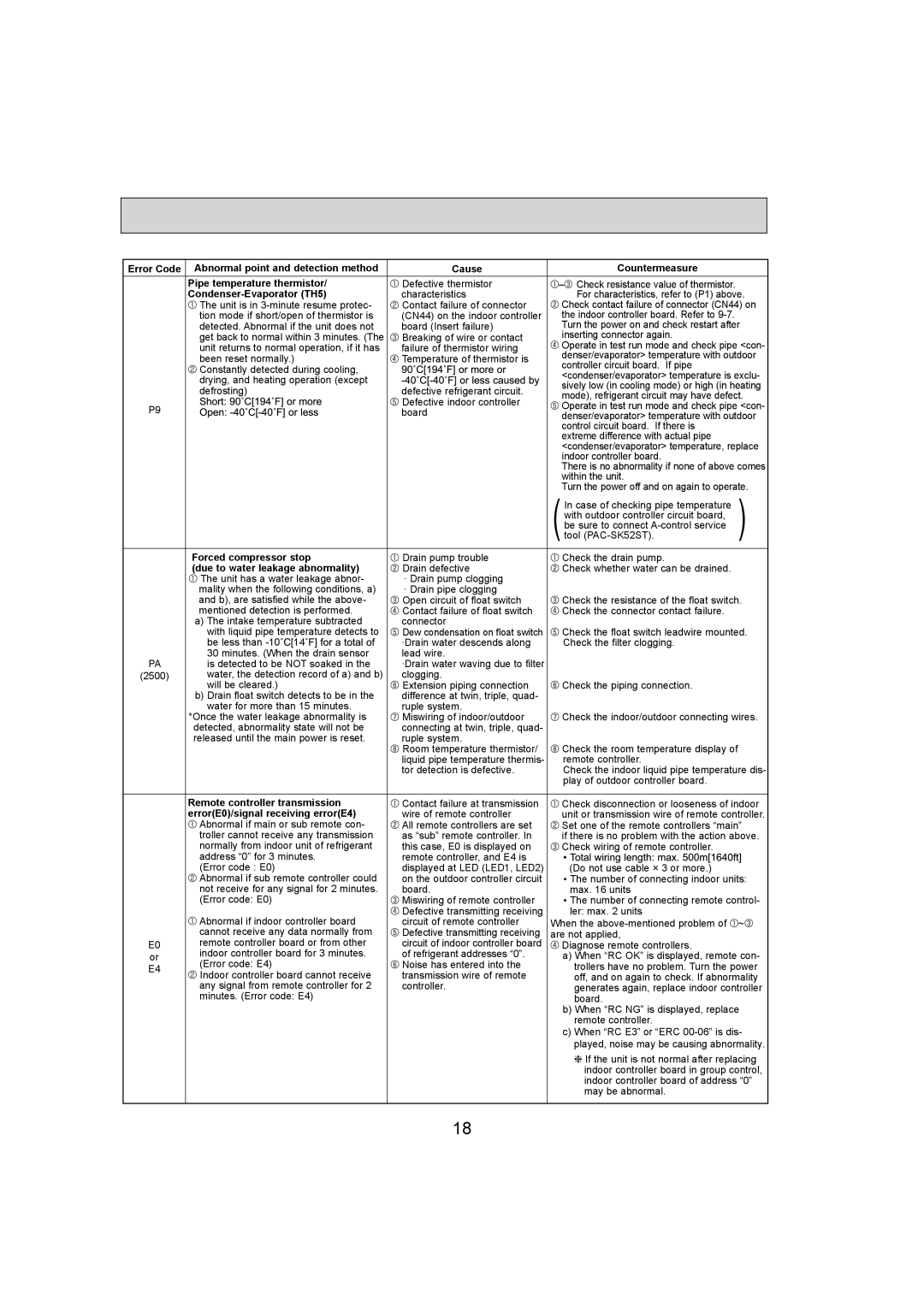

Error Code | Abnormal point and detection method | Cause | Countermeasure | |

| Pipe temperature thermistor/ | Defective thermistor | – Check resistance value of thermistor. | |

| Condenser-Evaporator (TH5) | characteristics | For characteristics, refer to (P1) above. |

| The unit is in 3-minute resume protec- | Contact failure of connector | Check contact failure of connector (CN44) on |

| tion mode if short/open of thermistor is | (CN44) on the indoor controller | the indoor controller board. Refer to 9-7. | |

| detected. Abnormal if the unit does not | board (Insert failure) | Turn the power on and check restart after |

| get back to normal within 3 minutes. (The | Breaking of wire or contact | inserting connector again. | |

| unit returns to normal operation, if it has | failure of thermistor wiring | Operate in test run mode and check pipe <con- |

| been reset normally.) | Temperature of thermistor is | denser/evaporator> temperature with outdoor |

| controller circuit board. If pipe | |

| Constantly detected during cooling, | | |

| | <condenser/evaporator> temperature is exclu- |

| drying, and heating operation (except | |

| | sively low (in cooling mode) or high (in heating |

| defrosting) | defective refrigerant circuit. |

| mode), refrigerant circuit may have defect. |

| | Defective indoor controller |

P9 | | Operate in test run mode and check pipe <con- |

| board |

| denser/evaporator> temperature with outdoor |

| | | control circuit board. If there is | |

| | | extreme difference with actual pipe | |

| | | <condenser/evaporator> temperature, replace |

| | | indoor controller board. | |

| | | There is no abnormality if none of above comes |

| | | within the unit. | |

| | | Turn the power off and on again to operate. |

| | | In case of checking pipe temperature | ) |

| | | with outdoor controller circuit board, |

| | | be sure to connect A-control service |

| | | (tool (PAC-SK52ST). |

| Forced compressor stop | Drain pump trouble | Check the drain pump. | |

| (due to water leakage abnormality) | Drain defective | Check whether water can be drained. | |

| The unit has a water leakage abnor- | · Drain pump clogging | | |

| mality when the following conditions, a) | · Drain pipe clogging | | |

| and b), are satisfied while the above- | Open circuit of float switch | Check the resistance of the float switch. |

| mentioned detection is performed. | Contact failure of float switch | Check the connector contact failure. | |

| a) The intake temperature subtracted | connector | | |

| with liquid pipe temperature detects to | Dew condensation on float switch | Check the float switch leadwire mounted. |

| be less than -10 [14 | ·Drain water descends along | Check the filter clogging. | |

| 30 minutes. (When the drain sensor | lead wire. | | |

PA | is detected to be NOT soaked in the | ·Drain water waving due to filter | | |

(2500) | water, the detection record of a) and b) | clogging. | Check the piping connection. | |

| will be cleared.) | Extension piping connection | |

| b) Drain float switch detects to be in the | difference at twin, triple, quad- | | |

| water for more than 15 minutes. | ruple system. | | |

| *Once the water leakage abnormality is | Miswiring of indoor/outdoor | Check the indoor/outdoor connecting wires. |

| detected, abnormality state will not be | connecting at twin, triple, quad- | | |

| released until the main power is reset. | ruple system. | Check the room temperature display of | |

| | Room temperature thermistor/ | |

| | liquid pipe temperature thermis- | remote controller. | |

| | tor detection is defective. | Check the indoor liquid pipe temperature dis- |

| | | play of outdoor controller board. | |

| | | |

| Remote controller transmission | Contact failure at transmission | Check disconnection or looseness of indoor |

| error(E0)/signal receiving error(E4) | wire of remote controller | unit or transmission wire of remote controller. |

| Abnormal if main or sub remote con- | All remote controllers are set | Set one of the remote controllers “main” |

| troller cannot receive any transmission | as “sub” remote controller. In | if there is no problem with the action above. |

| normally from indoor unit of refrigerant | this case, E0 is displayed on | Check wiring of remote controller. | |

| address “0” for 3 minutes. | remote controller, and E4 is | | |

| (Error code : E0) | displayed at LED (LED1, LED2) | (Do not use cable 3 or more.) | |

| Abnormal if sub remote controller could | on the outdoor controller circuit | • The number of connecting indoor units: |

| not receive for any signal for 2 minutes. | board. | max. 16 units | |

| (Error code: E0) | Miswiring of remote controller | • The number of connecting remote control- |

| Abnormal if indoor controller board | Defective transmitting receiving | ler: max. 2 units | |

| circuit of remote controller | When the above-mentioned problem of | ~ |

| cannot receive any data normally from | Defective transmitting receiving | are not applied, | |

E0 | remote controller board or from other | circuit of indoor controller board | Diagnose remote controllers. | |

or | indoor controller board for 3 minutes. | of refrigerant addresses “0”. | a) When “RC OK” is displayed, remote con- |

E4 | (Error code: E4) | Noise has entered into the | trollers have no problem. Turn the power |

| Indoor controller board cannot receive | transmission wire of remote | off, and on again to check. If abnormality |

| any signal from remote controller for 2 | controller. | generates again, replace indoor controller |

| minutes. (Error code: E4) | | board. | |

| | | b) When “RC NG” is displayed, replace |

| | | remote controller. | |

| | | c) When “RC E3” or “ERC 00-06” is dis- |

| | | played, noise may be causing abnormality. |

| | | If the unit is not normal after replacing |

| | | indoor controller board in group control, |

| | | indoor controller board of address “0” |

| | | may be abnormal. | |

| | | | |