SR1800C B-D specifications

The Nilfisk-ALTO SR1800C B-D is a powerful, efficient, and versatile ride-on scrubber drier designed for cleaning large areas in industrial, commercial, and retail environments. Combining advanced technology and user-friendly features, this machine streamlines the cleaning process while ensuring high-quality results.One of the standout features of the SR1800C B-D is its impressive cleaning capacity. With a working width of 800 mm, it can cover expansive areas in a shorter amount of time. The dual scrubbing brush system enhances cleaning efficiency, allowing for thorough dirt and grime removal in various surfaces, including tile, concrete, and linoleum. The machine’s robust build quality ensures durability and longevity even in the most demanding environments.

Another notable aspect of the SR1800C B-D is its innovative Ecoflex system. This technology allows users to adjust the detergent dosage and water flow according to the specific cleaning task at hand. By using just the right amount of resources, the Ecoflex system promotes sustainable cleaning practices, reduces water usage, and minimizes environmental impact without compromising cleaning performance.

The machine is equipped with a highly efficient vacuum system that enhances drying performance. This feature not only helps to expedite the cleaning process but also reduces slip hazards, making it a safer option for both staff and customers in high-traffic areas. The adjustable suction power ensures that various floor types can be cleaned effectively.

User comfort is also a priority in the design of the SR1800C B-D. Its ergonomic controls and adjustable seat make it easy to operate for extended periods, reducing operator fatigue. The clear visual display provides essential information, such as battery level and service alerts, ensuring that users can maintain the machine effectively.

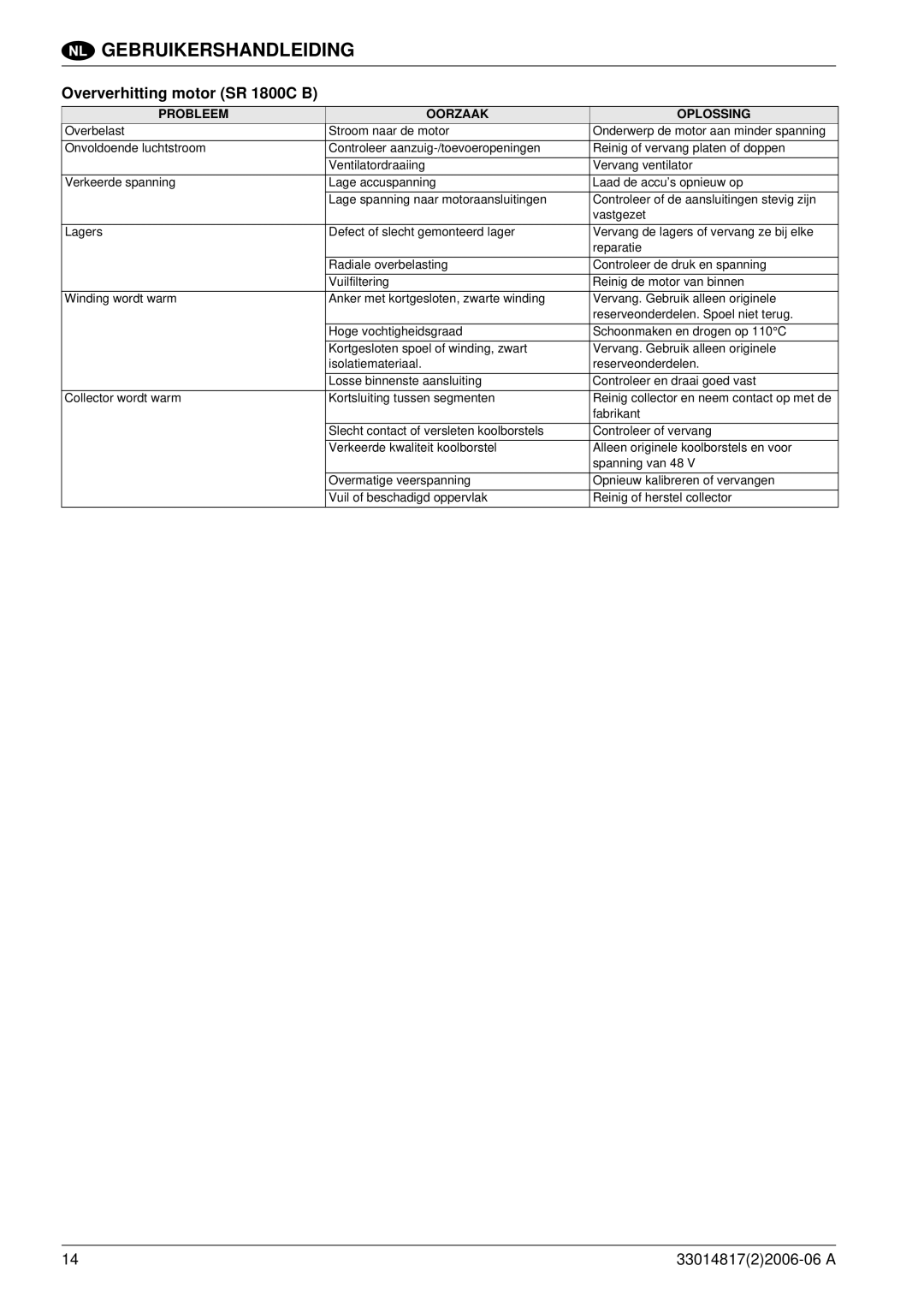

In terms of maintenance, the Nilfisk-ALTO SR1800C B-D is designed for easy access to components, simplifying routine tasks such as brush changes and tank cleaning. This thoughtful design significantly reduces downtime, allowing for consistent and uninterrupted cleaning operations.

In conclusion, the Nilfisk-ALTO SR1800C B-D offers an exceptional combination of efficiency, versatility, and user-friendly features. With its advanced cleaning technologies and focus on sustainability, this scrubber drier is an ideal choice for organizations looking to maintain cleanliness and safety in their facilities while optimizing operational costs.