LUBRICATE PRESSURE REGULATOR O-RINGS:

To maintain consistent adequate pressure delivery to the cleaning tool, the

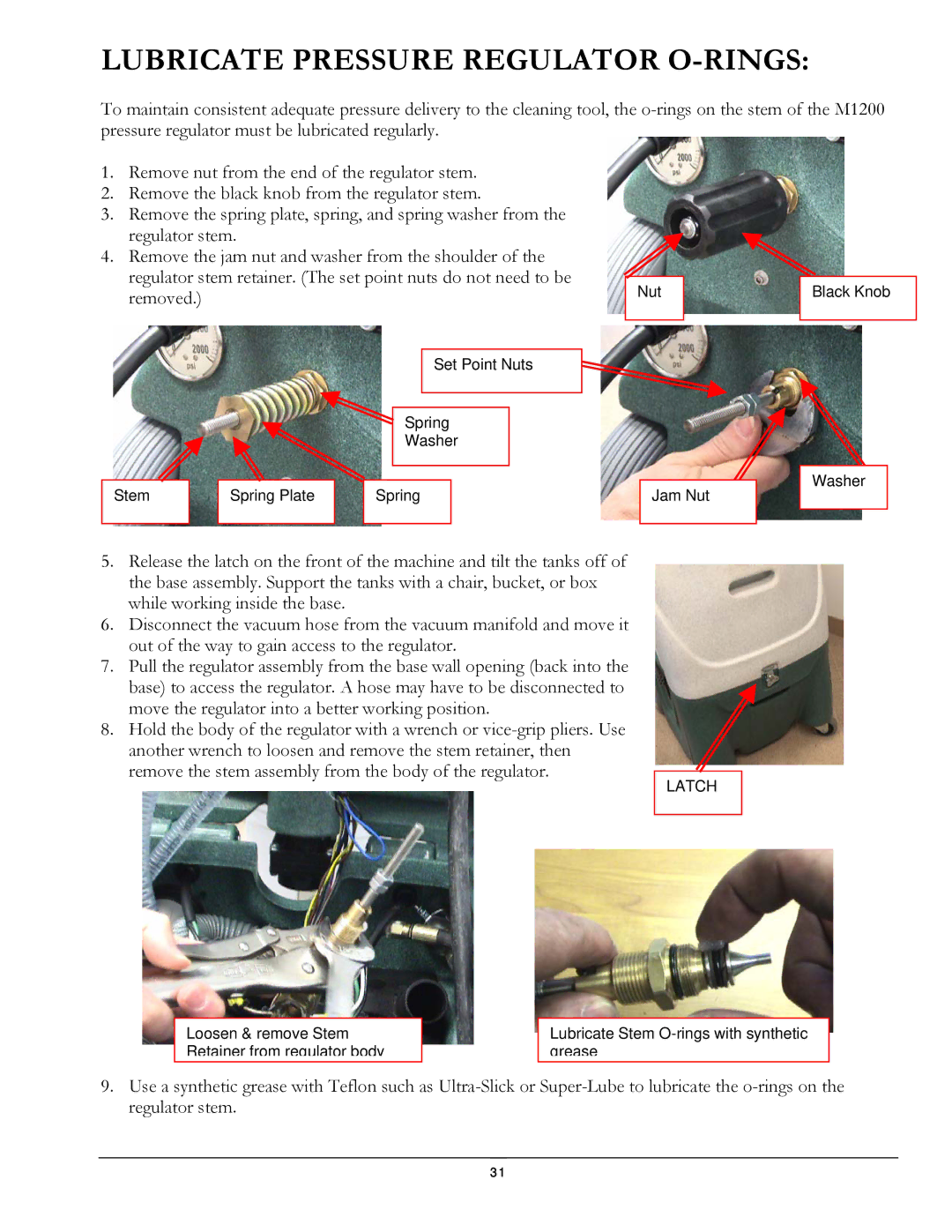

1.Remove nut from the end of the regulator stem.

2.Remove the black knob from the regulator stem.

3.Remove the spring plate, spring, and spring washer from the regulator stem.

4.Remove the jam nut and washer from the shoulder of the regulator stem retainer. (The set point nuts do not need to be removed.)

Set Point Nuts

Spring

Washer

Stem |

| Spring Plate |

| Spring |

|

|

|

|

|

Nut

Jam Nut

Black Knob

Washer

5.Release the latch on the front of the machine and tilt the tanks off of the base assembly. Support the tanks with a chair, bucket, or box while working inside the base.

6.Disconnect the vacuum hose from the vacuum manifold and move it out of the way to gain access to the regulator.

7.Pull the regulator assembly from the base wall opening (back into the base) to access the regulator. A hose may have to be disconnected to move the regulator into a better working position.

8.Hold the body of the regulator with a wrench or

LATCH

Loosen & remove Stem Retainer from regulator body

Lubricate Stem

9.Use a synthetic grease with Teflon such as

31