Model 3101RC Getting Started Guide | 4 • Operation |

|

|

Maintenance Requirement

Tools and Equipment Requirements

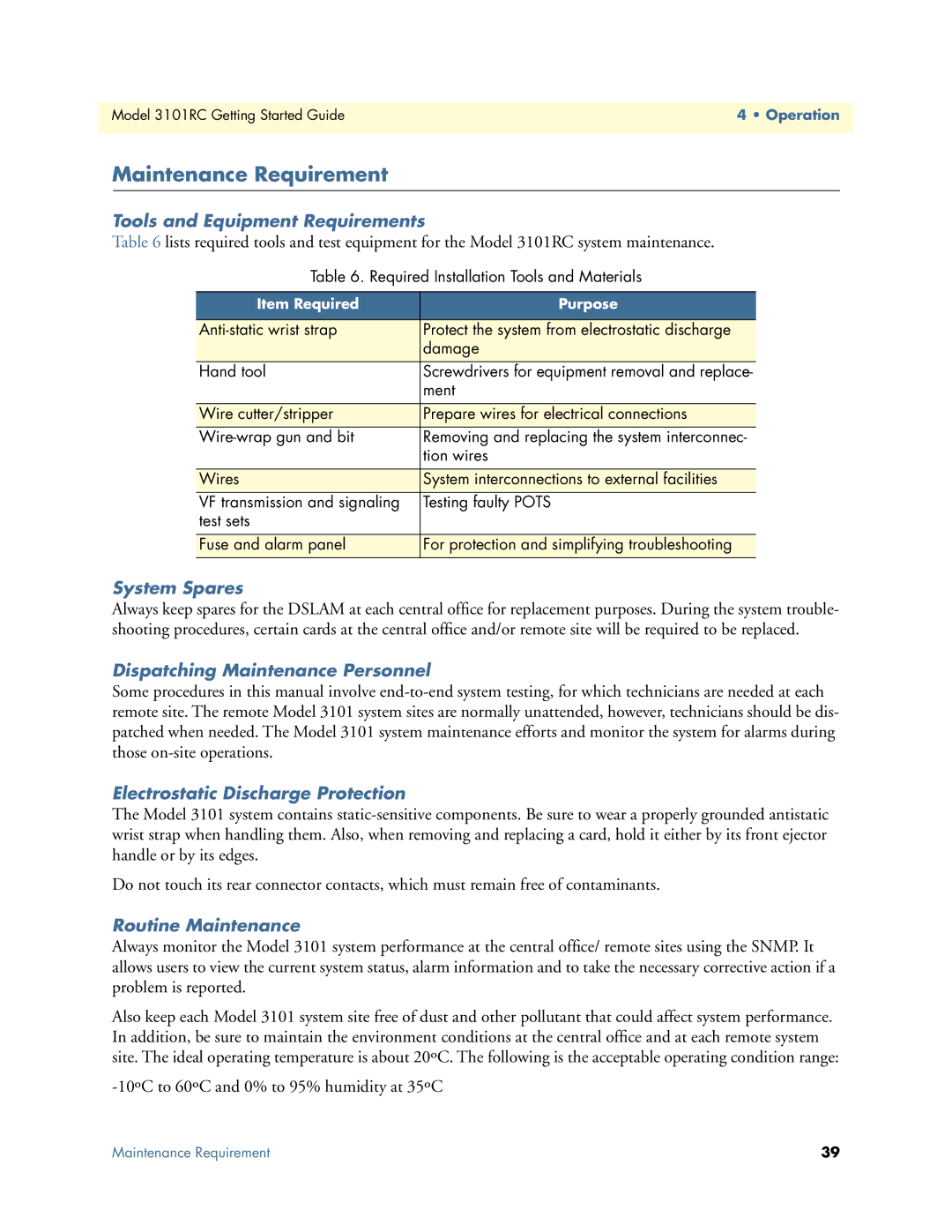

Table 6 lists required tools and test equipment for the Model 3101RC system maintenance.

Table 6. Required Installation Tools and Materials

Item Required | Purpose |

|

|

Protect the system from electrostatic discharge | |

| damage |

|

|

Hand tool | Screwdrivers for equipment removal and replace- |

| ment |

|

|

Wire cutter/stripper | Prepare wires for electrical connections |

|

|

Removing and replacing the system interconnec- | |

| tion wires |

|

|

Wires | System interconnections to external facilities |

|

|

VF transmission and signaling | Testing faulty POTS |

test sets |

|

|

|

Fuse and alarm panel | For protection and simplifying troubleshooting |

|

|

System Spares

Always keep spares for the DSLAM at each central office for replacement purposes. During the system trouble- shooting procedures, certain cards at the central office and/or remote site will be required to be replaced.

Dispatching Maintenance Personnel

Some procedures in this manual involve

Electrostatic Discharge Protection

The Model 3101 system contains

Do not touch its rear connector contacts, which must remain free of contaminants.

Routine Maintenance

Always monitor the Model 3101 system performance at the central office/ remote sites using the SNMP. It allows users to view the current system status, alarm information and to take the necessary corrective action if a problem is reported.

Also keep each Model 3101 system site free of dust and other pollutant that could affect system performance. In addition, be sure to maintain the environment conditions at the central office and at each remote system site. The ideal operating temperature is about 20ºC. The following is the acceptable operating condition range:

Maintenance Requirement | 39 |