Super Modular Multi System AIR Conditioner

Adoption of NEW Refrigerant

Contents

Separate sold parts

Refrigerant piping

Cable 3-core 2.5mm2, in conformity with Design 60245 IEC57

New Refrigerant Air Conditioner Installation

Precautions for Safety

Precautions for Safety

Selection of Installation Place

Pipe connecting position

Installation space

Front view

Bottom view

Selection of Installation Place

Installation of Indoor Unit

Case of wireless type

„ In case of wooden construction Wide wall

Installation of installation plate

„ In case of reinforced concrete construction

„ In case of rear direction piping

Installation of indoor unit

Installation of Indoor Unit

Drain Piping Work

Installation of remote controller Sold separately

Piping and Insulation

Pipe and Drain hose formation

Refrigerant Piping

Piping material and dimensions

Permissible pipe length and permissible height difference

Pipe Forming/End Positioning

Airtight test/Air purge, etc

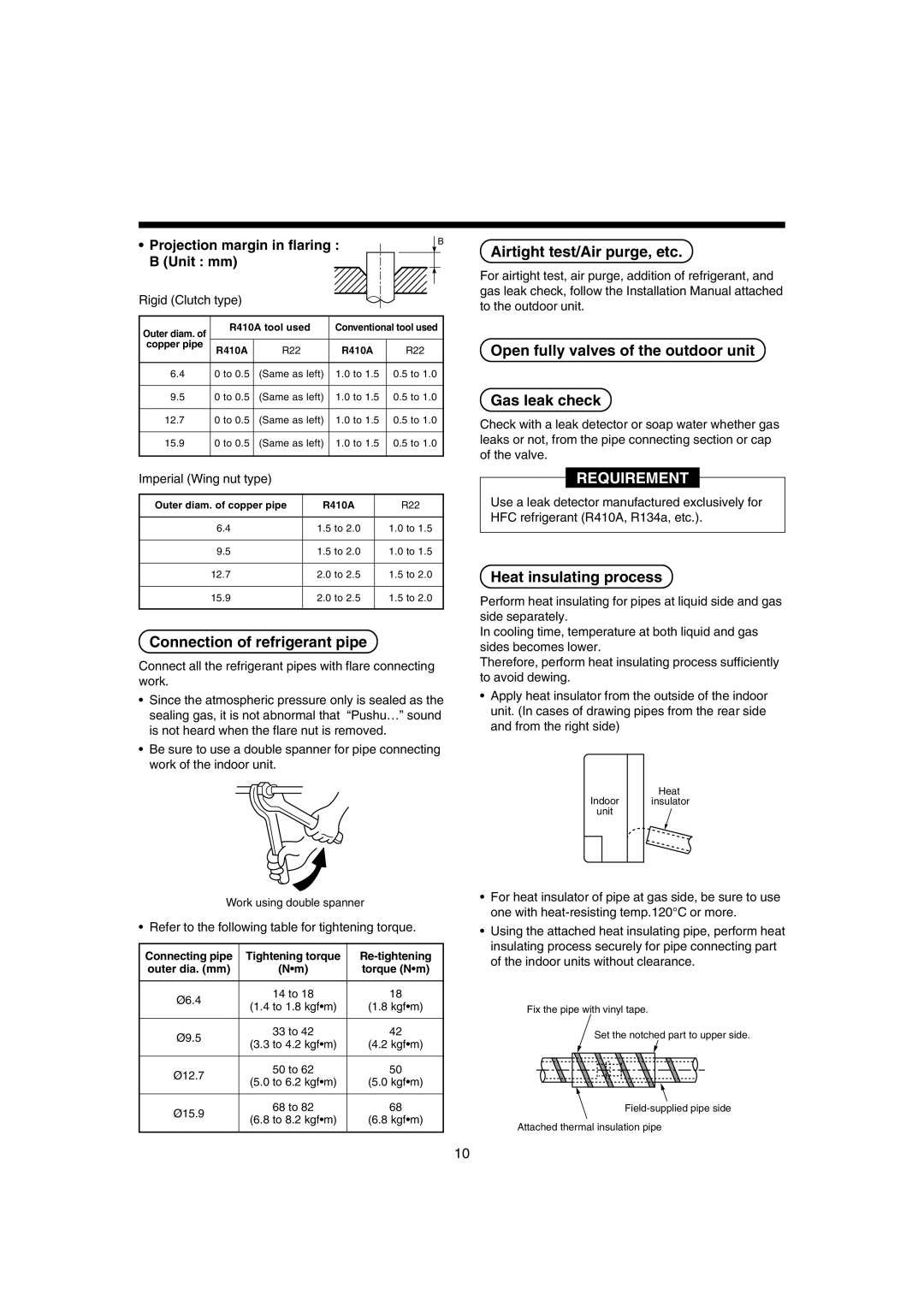

Connection of refrigerant pipe

Open fully valves of the outdoor unit Gas leak check

Heat insulating process

Be sure to install an earth leakage breaker

Power supply specifications

Electric Work

Indoor/Outdoor inter-unit wiring, Central controller wiring

Indoor unit power supply *1

Remote controller wiring

Cable connection

Wiring between indoor and outdoor units

Remote controller wiring

Address setup

Wiring diagram

Basic operation procedure for setup exchange

Exchange of applicable control setup

Applicable Controls

Notification

Applicable Controls

Adjustment of air direction

Change of lighting time of filter sign

To secure better effect of heating

Case of wired remote controller

How to execute test operation

Procedure

Test RUN

Test RUN

Case of wireless remote controller

Confirmation of error history

Troubleshooting

Confirmation and check

Check code list

Troubleshooting

Check method

Terminology

ALT

Error detected by TCC-LINK central control device

Display on sensor part of wireless

Display on wired remote controller

New check code

Special mention

Pièces vendues séparément

Tuyaux de réfrigérant

Utilisation

Nom de la pièce Quantité Forme

Avertissement

Mesures DE Securite

Pour déconnecter l’appareil du secteur

Branchez correctement le câble de raccordement

Mesures DE Securite

Selection DU Lieu D’INSTALLATION

Position de raccordement de tuyau

Espace requis pour l’installation

Vue avant

Vue du bas

Selection DU Lieu D’INSTALLATION

Installation DE L’UNITE Interieure

Sur les types sans-fil

„ Dans une construction en bois mur large

Installation de la plaque d’installation

„ Sur les construction en béton armé

„ Lorsque la tuyauterie est orientée vers l’arrière

Installation de l’unité intérieure

Installation DE L’UNITE Interieure

„ Enlèvement de la plaque droite de l’unité intérieure

„ Lorsque la tuyauterie est orientée vers la gauche

Prudence

Installation de la télécommande vendue séparément

Tuyauterie et isolation

Formation du tuyau et du tuyau flexible d’évacuation

Dimension en mètres du Diamètre de ’évasement a Unité

Tuyauterie et dimensions

Tuyaux DE Réfrigérant

Mise en forme/Pose définitive des tuyaux

Test d’étanchéité/Purge d’air, etc

Raccordement du tuyau de réfrigérant

Procédé de calorifugeage

Marge de projection de ’évasement Unité mm

Caractéristiques de l’alimentation électrique

Travaux D’ÉLECTRICITÉ

Assurez-vous de raccorder le fil de terre. Mise à la terre

Raccordement des câbles

Câbles de la télécommande *4

Alimentation électrique de l’unité intérieure *1

Configuration de l’adresse

Raccordement des télécommandes

Travaux D’ÉLECTRICITÉ

Câblage de liaison entre unités intérieure et extérieure

Modification de la configuration de la commande possible

Commandes Utilisables

Procédure de base pour modifier la configuration

Adresses automatiques

Commande de groupe

Commandes Utilisables

Modification du temps d’éclairage de la minuterie du filtre

Pour garantir un meilleur chauffage

En cas de télécommande avec fil

Mode d’exécution d’un essai de fonctionnement

Essai DE Fonctionnement

Remarque

Essai DE Fonctionnement

Avec une télécommande sans-fil

Procédure

Confirmation et vérification

Dépannage

Confirmation de l’historique de pannes

Liste des codes de vérification

Dépannage

Terminologie

Afficheur extérieur à 7 segments

Principale Code auxiliaire Centrale AI NET

Affichage sur capteur télécommande sans-fil

Affichage sur télécommande à fil

Affichage sur indicateur du récepteur télécommande sans-fil

Nouveau code de vérification

Getrennt erhältliche Teile

Kühlmittel-Leitungssystem

Adrig 2.5 mm², entsprechend 60425 IEC57

Warnung

Sicherheitsvorkehrungen

Vorsicht Trennen des Geräts von der Hauptstromversorgung

Sicherheitsvorkehrungen

Auswahl DES Aufstellungsortes

Vorsicht

Rohrleitungsanschluss

Platzbedarf

Vorderansicht

Ansicht von unten

Auswahl DES Aufstellungsortes

Installation DER Raumeinheit

Für drahtlose Fernbedienungen

„ Bei Holzkonstruktionen Holzständerwand

Installation der Montageplatte

„ Bei Stahlbetonwänden

„ Rohrleitungsführung nach hinten

Installation der Inneneinheit

Installation DER Raumeinheit

Rohrleitungen und Isolierung

Installation der Fernbedienung getrennt erhältlich

Anordnung von Rohrleitungen und Kondensatschlauch

Rohrleitungen

Erlaubte Rohrleitungslängen und erlaubte Höhendifferenzen

Kühlmittelleitungen

Rohrmaterial und Abmessungen

Biegen und Positionieren

Anschluss der Kühlmittelleitung

Dichtetest/Entlüftung usw

Wärmeisolierung

Bördelhöhe B Einheit mm

Spezifikation der Stromversorgung

Elektroarbeiten

Verlegen Sie auch eine Masseleitung. Masse anschließen

Stromversorgung Raumeinheit

Kabelanschlüsse

Verkabelung der Fernbedienung

Verkabelung der Fernbedienung

Elektroarbeiten

Verbindungskabel zwischen Raum- und Außeneinheit

Adress-Einstellung

Hinweise

Steuerungsmöglichkeiten

Änderung der Steuerungsvorgaben

Automatische Adressierung

Änderung der Zeitvorgabe für die Filterwarnleuchte

Steuerungsmöglichkeiten

Verbesserung der Heizleistung

Einstellung der Lüftungsrichtung

Hinweis

Testlauf

Vorbereitung

Ablauf des Tests

Infrarot-Fernbedienung

Testlauf

Bestätigung und Prüfung

Fehlersuche

Aufruf des Fehlerspeichers

Liste der Fehlercodes

Fehlersuche

Funktion Uhr Bereit Blinken F01

C06 C12

Fehler durch zentrale Überwachung TCC-LINK erkannt

Anzeige bei verdrahteter Fernbedienung

Neuer Prüfcode

Anzeige auf Empfangsteil der Infrarot-Fernbedienung

Spezielle Bemerkung

Parti da acquistare a parte

Tubazioni del refrigerante

Utilizzo

SForma

Avvertenza

Precauzioni PER LA Sicurezza

Attenzione

Collegare il cavo di connessione in modo corretto

Evitare l’installazione nei posti seguenti

Scelta DEL Posto D’INSTALLAZIONE

Precauzioni PER LA Sicurezza

Posizione di connessione del tubo

Spazio per l’installazione

Vista anteriore

Vista dal basso

Scelta DEL Posto D’INSTALLAZIONE

Installazione DELL’UNITÀ Interna

Nel caso del tipo via radio

„ Nel caso di una costruzione di legno muro laterale

Installazione della piastra per l’installazione

„ Nel caso di tubo in direzione posteriore

Modello MMK Peso kg Da 0071H a 0121H Da 0151H a 0181H 0241H

Installazione dell’unità interna

Installazione DELL’UNITÀ Interna

„ Nel caso di tubo in direzione posteriore e destra

„ Nel caso di tubo in direzione sinistra

Lavoro PER LA Tubazione DI Scarico

Installazione del pannello del soffitto in vendita a parte

Tubazione e isolamento

Sinistro o sul lato destro dell’unità

Svasatura Dimensione misuratore dia Svasatura a Unità mm

Materiale per tubature e dimensioni

Tubazioni DEL Refrigerante

Formatura tubi/Posizionamento estremità

Connessione del tubo del refrigerante

Prove di tenuta d’aria/Sfiato aria, ecc

Procedura per isolamento termico

Margine di protezione Svasatura Unità mm

Collegamenti Elettrici

Installare un interruttore di collegamento a terra

Dati tecnici per alimentazione elettrica

Alimentazione elettrica dell’unità interna

Collegamento dei cavi

Collegamenti elettrici del telecomando

Collegamenti Elettrici

Schema dei collegamenti elettrici

Posa in opera dei cavi per il telecomando

Collegamenti elettrici fra unità interna e esterna

Avviso

Comandi Applicabili

Scambio di impostazioni dei comandi applicabili

Indirizzamento automatico

Modifica del tempo di accensione del simbolo del filtro

Comandi Applicabili

Per garantire una resa migliore del riscaldamento

Regolazione della direzione dell’aria

Nota

Funzionamento DI Prova

Prima del funzionamento di prova

Come avviare il funzionamento di prova

Caso di telecomando via radio

Funzionamento DI Prova

Conferma della casistica di errori

Risoluzione DEI Problemi

Conferma e controllo

Lista dei codici di controllo

Risoluzione DEI Problemi

Terminologia

Errore sensore TCJ unità interna

Errore motore ventola unità interna

Nuovo codice di controllo

Componentes vendidos por separado

Tubería de refrigerante

Nombre del

Utilización

Precaución

Precauciones Para SU Seguridad

Advertencia

Conecte el cable de conexión correctamente

Precauciones Para SU Seguridad

Selección DEL Lugar DE Instalación

Evite la instalación en los siguientes lugares

Posición de conexión de la tubería

Espacio de instalación

Vista frontal

Vista inferior

Selección DEL Lugar DE Instalación

Instalación DE LA Unidad Interior

En el caso de mando a inalámbrico

„ En casos de construcciones en madera Muro ancho

Montaje de la placa de instalación

„ En caso de construcciones de hormigón armado

„ Para los tubos posteriores

Instalación de la unidad de interior

Instalación DE LA Unidad Interior

„ Para los tubos posteriores y del lado derecho

„ Para los tubos laterales derechos

Tubería

Formación del tubo y el desagüe

Tubería DE Regrigerante

Material y dimensiones de la tubería

Longitud del tubo y diferencia de altura permisibles

Moldeado de los tubos / Posición final

Conexión del tubo de refrigerante

Prueba de hermetizado, purga de aire, etc

Proceso de aislamiento térmico

Margen de proyección en El abocinado Unidad mm

Especificaciones de la alimentación eléctrica

Instalación Eléctrica

Instale un disyuntor de fugas a tierra

Alimentación eléctrica de la unidad interior

Conexión de los cables

Cableado del mando a distancia

Diagrama del cableado

Configuración de las identificaciones

Instalación Eléctrica

Cableado del mando a distancia

Procedimiento básico para cambiar la configuración

Cambio en la configuración de los controles aplicables

Controles Aplicables

Notificación

Cambiar momento de encendido de la señal de filtro

Controles Aplicables

Para mejorar el efecto calefactor

Ajustes para la dirección del aire

Antes de llevar a cabo la prueba

Prueba DE Funcionamiento

Cómo realizar una prueba de funcionamiento

En el caso de mando a distancia con cable

En caso de utilizar un control remoto inalámbrico

Prueba DE Funcionamiento

Confirmación del historial de errores

Resolución DE Problemas

Confirmación y verificación

Lista de códigos de verificación

Resolución DE Problemas

Terminología

108

109

Nuevo código de verificación

Peças vendidas em separado

Tubagem de refrigerante

Desenhada 60245 IEC57

Precauções

Precauções DE Segurança

Aviso

Instalação de Ar Condicionado de Novo Refrigerante

Precauções DE Segurança

Selecção do Local DE Instalação

Cuidado

Evite instalar a unidade nos seguintes locais

Posição da ligação dos tubos

Espaço de instalação

Tubo do lado da Peças a serem removidas Tubagem

Selecção do Local DE Instalação

Instalação DA Unidade Interior

No caso do tipo sem cabos

„ No caso de construção de Madeira Parede de madeira

Instalação da chapa de instalação

„ No caso de construção de betão armado

„ No caso de tubagem direccionada para trás

Instalação da unidade interior

Instalação DA Unidade Interior

„ Remover o painel do lado direito da unidade interior

„ No caso de tubagem do direccionada para o lado esquerdo

Ciudado

Instalação DA Tubagem DE Drenagem

Tubagem e isolamento

Formação dos tubos e mangueira de drenagem

Material e dimensões de tubagem

Tubagem DE Refrigerante

Definição da Tubagem / Posição dos Extremos

Alargamento Diâmetro de alargamento Unidade mm

Teste de hermeticidade/Purga de ar, etc

Ligação do tubo de refrigerante

Processo de isolamento térmico

Especificações da alimentação eléctrica

Trabalhos DE Electricidade

Não se esqueça de ligar o cabo de terra. Ligação à terra

Alimentação eléctrica da unidade interior

Ligação de cabos

Cabos do controlador remoto

Trabalhos DE Electricidade

Diagrama de ligações

Ligações do controlador remoto

Ligações entre as unidades interiores e exteriores

Procedimento da operação básica para troca de configuração

Troca da configuração de controlo aplicável

Controlos Aplicáveis

Endereçamento automático

Mude o tempo de iluminação do sinal do filtro

Controlos Aplicáveis

Para garantir um melhor efeito do aquecimento

Ajuste da direcção do ar

Avisos

Teste DE Funcionamento

Antes do teste de funcionamento

Como efectuar um teste

No caso de controlador remoto sem cabos

Teste DE Funcionamento

Confirmação e verificação

Resolução DE Problemas

Confirmação de historial de erros

Procedimento

Lista de códigos de erros

Resolução DE Problemas

130

Erro detectado pelo dispositivo de controlo central TCC-LINK

Novo código de verificação

Niet meegeleverde onderdelen

Koelmiddelleidingen

Toepassing

Vorm

LET OP

Installeren van een airconditioner met een nieuw koelmiddel

Waarschuwing

Het apparaat loskoppelen van de netvoeding

Voorzorgsmaatregelen Voor UW Veiligheid

Installeer de airconditioner niet op de volgende plaatsen

Leidingaansluitingspositie

Installatieruimte

Vooraanzicht

Onderaanzicht

Keuze VAN DE Locatie Voor DE Installatie

Installatie VAN DE Binnenunit

Bij een draadloos model

„ Bij installatie van de leidingen via de achterzijde

De installatieplaat installeren

„ Bij een houten constructie holle wand

„ Bij een constructie uit gewapend beton

Installatie van de binnenunit

Installatie VAN DE Binnenunit

„ Bij installatie van de leidingen via de linkerzijde

„ Bij installatie van de leidingen via de rechterzijde

Leidingen en isolatie

Afvoerleidingen

Leidingen en afvoerslang buigen

Toegestane leidinglengte en hoogteverschil

Koelmiddelleidingen

Leidingmateriaal en -afmetingen

Leidingen buigen Bepalen van het uiteinde van de leidingen

Gasdichtheid testen Ontluchten enzovoort

Aansluiten van koelmiddelleidingen

Isoleren

Uitstekende leidinglengte Bij trompen Eenheid mm

Elektrische Bedrading

Installeer altijd een aardlekschakelaar

Voedingspecificaties

Controleer of de aardingsaansluiting is gemonteerd. Aarding

Bekabeling voor de afstandsbediening *4

Voeding binnenunit *1

Elektrische Bedrading

Aansluitschema

Bekabeling van de afstandsbediening

Bekabeling tussen de binnen- en buitenunits

Belangrijk

Bedieningselementen

Wijzigen van de instellingen

Automatische adressering

De verwarmingscapaciteit optimaliseren

Bedieningselementen

De uitblaasrichting instellen

Groepsbediening

Opmerking

Werkingstest

Voordat u een werkingstest uitvoert

Zo voert u de werkingstest uit

Bij gebruik van een draadloze afstandsbediening

Werkingstest

Controles

Storingen Verhelpen

Storingscodes opslaan

Storingscodelijst

Storingen Verhelpen

152

153

Nieuwe storingscode

ÅîáñôÞìáôá ðïõ ðùëïýíôáé îå÷ùñéóôÜ

Óùëçíþóåéò øõêôéêïý ìÝóïõ

Ðñïöõëáîåéó Áóöáëåéáó

Åðéëïãç ÔÏÕ ×ÙÑÏÕ Åãêáôáóôáóçó

ÈÝóç óýíäåóçò óùëÞíùí

×þñïò åãêáôÜóôáóçò

Ãéá ôçí ðåñßðôùóç áóýñìáôïõ ôýðïõ

Åðéëïãç ÔÏÕ ×ÙÑÏÕ Åãêáôáóôáóçó

„ Óå ðåñßðôùóç îýëéíçò êáôáóêåõÞò Ìáêñýò ôïß÷ïò

ÅãêáôÜóôáóç ôçò ðëÜêáò åãêáôÜóôáóçò

ÅãêáôÜóôáóç ôçò åóùôåñéêÞò ìïíÜäáò

Åãêáôáóôáóç ÔÇÓ Åóùôåñéêçó Ìïíáäáó

ÅãêáôÜóôáóç ôïõ ôçëå÷åéñéóôçñßïõ Ðùëåßôáé îå÷ùñéóôÜ

ÓùëÞíùóç êáé Ìüíùóç

Õëéêü êáé äéáóôÜóåéò óùëÞíùóçò

Åðéôñåðüìåíï ìÞêïò óùëÞíá êáé åðéôñåðüìåíç äéáöïñÜ ýøïõò

Ìïñöïðïßçóç óùëÞíùí / ÈÝóç Üêñùí

Óýíäåóç ôïõ óùëÞíá áðïóôñÜããéóçò

ÄïêéìÞ áåñïóôåãáíüôçôáò / ÅêêÝíùóç áÝñá, êëð

Äéáäéêáóßá èåñìïìüíùóçò

ÐñïäéáãñáöÝò ðáñï÷Þò ñåýìáôïò

Çëåêôñéêç Åñãáóéá

Ðáñï÷Þ ñåýìáôïò ôçò åóùôåñéêÞò ìïíÜäáò

Óýíäåóç êáëùäßùí

Êáëùäßùóç ìåôáîý åóùôåñéêÞò êáé åîùôåñéêÞò ìïíÜäáò

Êáëùäßùóç ôçëå÷åéñéóôçñßïõ

Ñýèìéóç ôçò äéåýèõíóçò

ÁëëáãÞ ñõèìßóåùí åöáñìüóéìùí åíôïëþí

Åöáñìïóéìïé ÅËÅÃ×ÏÉ

Ñýèìéóç êáôåýèõíóçò ôïõ áÝñá

ÁëëáãÞ ôïõ ÷ñüíïõ áíÜììáôïò ôïõ óÞìáôïò ôïõ ößëôñïõ

Ïìáäéêüò Ýëåã÷ïò

Ðþò íá êÜíåôå ôç äïêéìÞ ëåéôïõñãßáò

Ðñéí ôç äéáäéêáóßá äïêéìÞò

Äïêéìç Ëåéôïõñãéáó

Åðéâåâáßùóç éóôïñéêïý óöáëìÜôùí

Åðéâåâáßùóç êáé Ýëåã÷ïò

Ëßóôá êùäéêþí åëÝã÷ïõ

Áíôéìåôùðéóç Ðñïâëçìáôùí

174

175

Êùäéêüò åëÝã÷ïõ óôï ôñÝ÷ïí óýóôçìá ÍÝïò êùäéêüò åëÝã÷ïõ

ÍÝïò êùäéêüò åëÝã÷ïõ

Check of Concentration Limit

Indoor unit setup check sheet

Confirmation of Indoor Unit Setup