QV36A-FB specifications

The Quadra-Fire QV36A-FB is a remarkable direct vent gas fireplace that combines beauty, efficiency, and innovative technology to create a cozy ambiance in any home. This fireplace is designed for those seeking an aesthetically pleasing yet highly functional heating solution.One of the standout features of the QV36A-FB is its impressive heating capacity. With the ability to produce up to 34,000 BTUs, it effectively warms spaces of various sizes, making it suitable for both small and large living areas. Its impressive efficiency rating maximizes heat output while minimizing gas consumption, ensuring that homeowners can enjoy warmth without the worry of excessive energy bills.

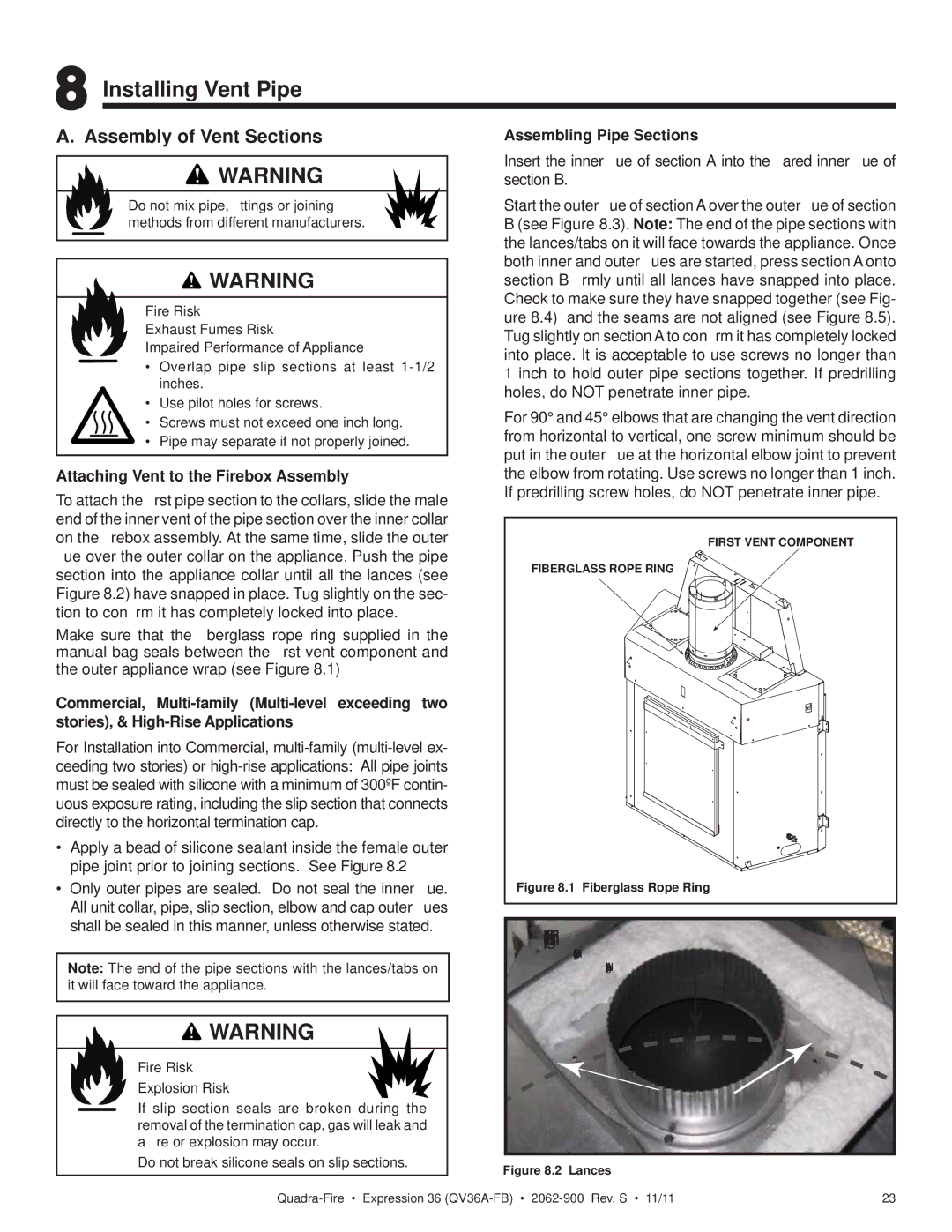

The QV36A-FB employs a direct venting system, allowing for safe and efficient operation. This system draws air from outside for combustion, which is particularly beneficial for maintaining indoor air quality. The use of direct venting minimizes the loss of heated air, ensuring maximum efficiency and comfort. It also features a versatile installation design that provides flexibility to fit various home layouts.

In terms of aesthetics, the Quadra-Fire QV36A-FB does not disappoint. The fireplace boasts a sleek, contemporary design, available in multiple finishes that easily complement any interior decor. Customers can choose from a variety of logs and ember beds to customize the appearance of the fire, creating a personalized focal point that enhances the ambiance of their living space.

Another significant feature is its advanced ignition system, which ensures reliable and hassle-free starting. The QV36A-FB is equipped with a convenient remote control option that allows users to adjust flame height and heat output with ease, providing exceptional comfort without the need to manually tend to the fire.

This fireplace also incorporates several safety mechanisms, including a flame sensor and a safety shut-off feature, ensuring worry-free operation for families with children or pets. The combination of elegance, efficiency, and state-of-the-art technology makes the Quadra-Fire QV36A-FB a preferred choice for homeowners seeking a premium gas fireplace solution.

In conclusion, the QV36A-FB is more than just a heat source; it is a stylish addition that enhances home aesthetics while delivering reliable warmth. With its impressive features and innovative technologies, it stands out as a dependable choice in the world of gas fireplaces.