Y-200 specifications

The Raypak Y-200 is a sophisticated and robust swimming pool heater that is designed for efficiency, durability, and optimal performance. Ideal for both residential and commercial pools, the Y-200 is equipped with advanced technology to ensure a seamless heating experience, catering to pool owners who prioritize quality and reliability.One of the main features of the Raypak Y-200 is its impressive heating capacity. With a powerful heater that can efficiently raise the temperature of water in larger pools, users can enjoy comfortable swimming conditions year-round. The heater is designed to be easy to install and maintain, allowing for hassle-free integration into existing pool systems.

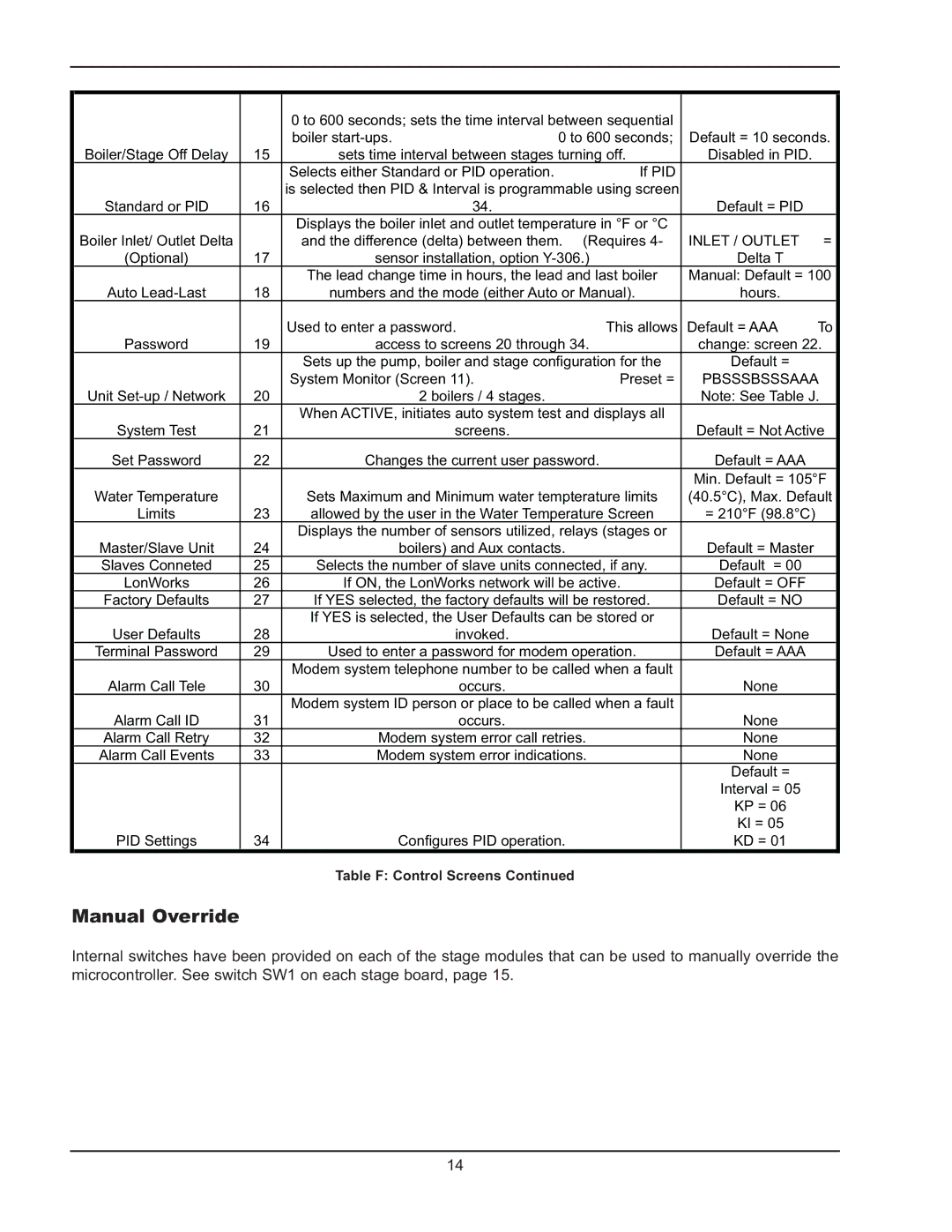

The Y-200 utilizes innovative digital controls, which give users precise measurement and adjustment capabilities. This includes a user-friendly display that provides real-time feedback on temperature settings and operational status. The digital interface makes it simple to program the heater according to individual preferences, ensuring that water is always at the desired temperature.

In terms of energy efficiency, the Raypak Y-200 boasts advanced technology that reduces energy consumption while maximizing heat output. The heater is designed with a reliable and robust heat exchanger that utilizes copper fin technology, providing excellent thermal conductivity and corrosion resistance. This ensures longevity and reduces the need for frequent maintenance.

Additionally, the Y-200 incorporates environmentally friendly technologies, including low-NOx emissions, aligning with modern standards for sustainability. This feature not only minimizes the environmental impact but also assists in meeting local regulations concerning emissions.

Durability is a hallmark of the Raypak Y-200. Constructed with high-quality materials designed to withstand the rigors of outdoor conditions, it provides users with peace of mind knowing that their investment is protected. The heater is also equipped with a weather-resistant cabinet, ensuring reliable operation regardless of climate.

In conclusion, the Raypak Y-200 stands out in the market due to its powerful heating capacity, advanced digital controls, energy-efficient technologies, and durable construction. It is an excellent choice for pool owners seeking a dependable and efficient heating solution to enhance their swimming experience. With its combination of high performance and user-friendly features, the Y-200 represents a valuable addition to any pool setting.