GENERAL SAFETY PRECAUTIONS

The cutting teeth need to be sharpened when:

•Sawdust becomes

•You need extra force to saw in

•The cut way does not go straight

•Vibration increases

•Fuel consumpion increases

Sharpening cutting teeth

Important Always wear gloves, when working with the chain, in order to protect your hands from injury.

Make sure the saw chain is held securely, before filing!

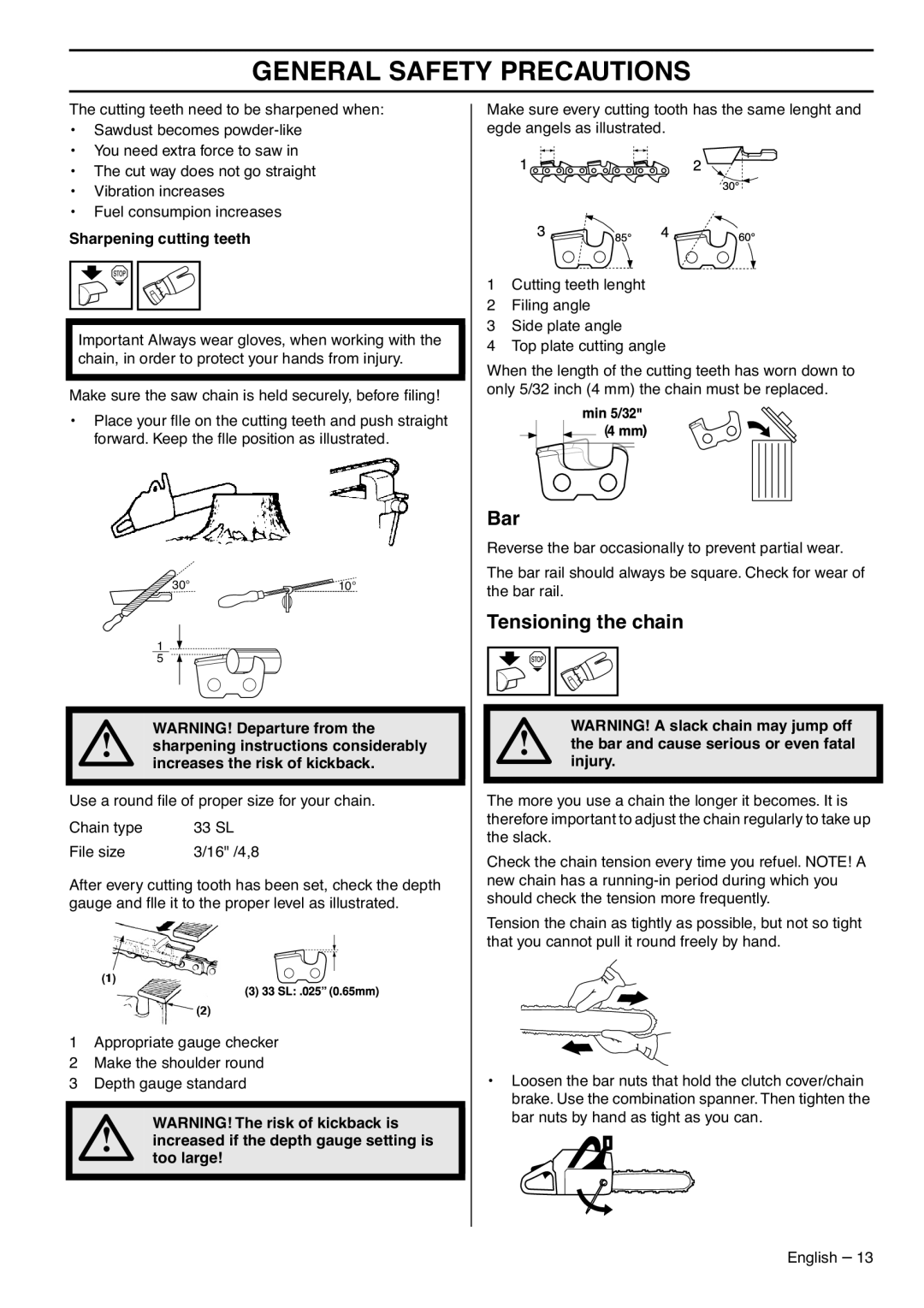

•Place your flle on the cutting teeth and push straight forward. Keep the flle position as illustrated.

30° | 10° |

1

5

WARNING! Departure from the

! sharpening instructions considerably

increases the risk of kickback.

Use a round file of proper size for your chain.

Chain type | 33 SL |

File size | 3/16" /4,8 |

After every cutting tooth has been set, check the depth gauge and flle it to the proper level as illustrated.

1Appropriate gauge checker

2 Make the shoulder round

3 Depth gauge standard

| ! | WARNING! The risk of kickback is |

| increased if the depth gauge setting is | |

|

| too large! |

|

|

|

Make sure every cutting tooth has the same lenght and egde angels as illustrated.

1Cutting teeth lenght

2 Filing angle

3 Side plate angle

4 Top plate cutting angle

When the length of the cutting teeth has worn down to only 5/32 inch (4 mm) the chain must be replaced.

Bar

Reverse the bar occasionally to prevent partial wear.

The bar rail should always be square. Check for wear of the bar rail.

Tensioning the chain

WARNING! A slack chain may jump off ! the bar and cause serious or even fatal

injury.

The more you use a chain the longer it becomes. It is therefore important to adjust the chain regularly to take up the slack.

Check the chain tension every time you refuel. NOTE! A new chain has a

Tension the chain as tightly as possible, but not so tight that you cannot pull it round freely by hand.

•Loosen the bar nuts that hold the clutch cover/chain brake. Use the combination spanner.Then tighten the bar nuts by hand as tight as you can.

English – 13