INSTALLATION

UNIT ASSEMBLY

PRIOR TO INSTALLATION

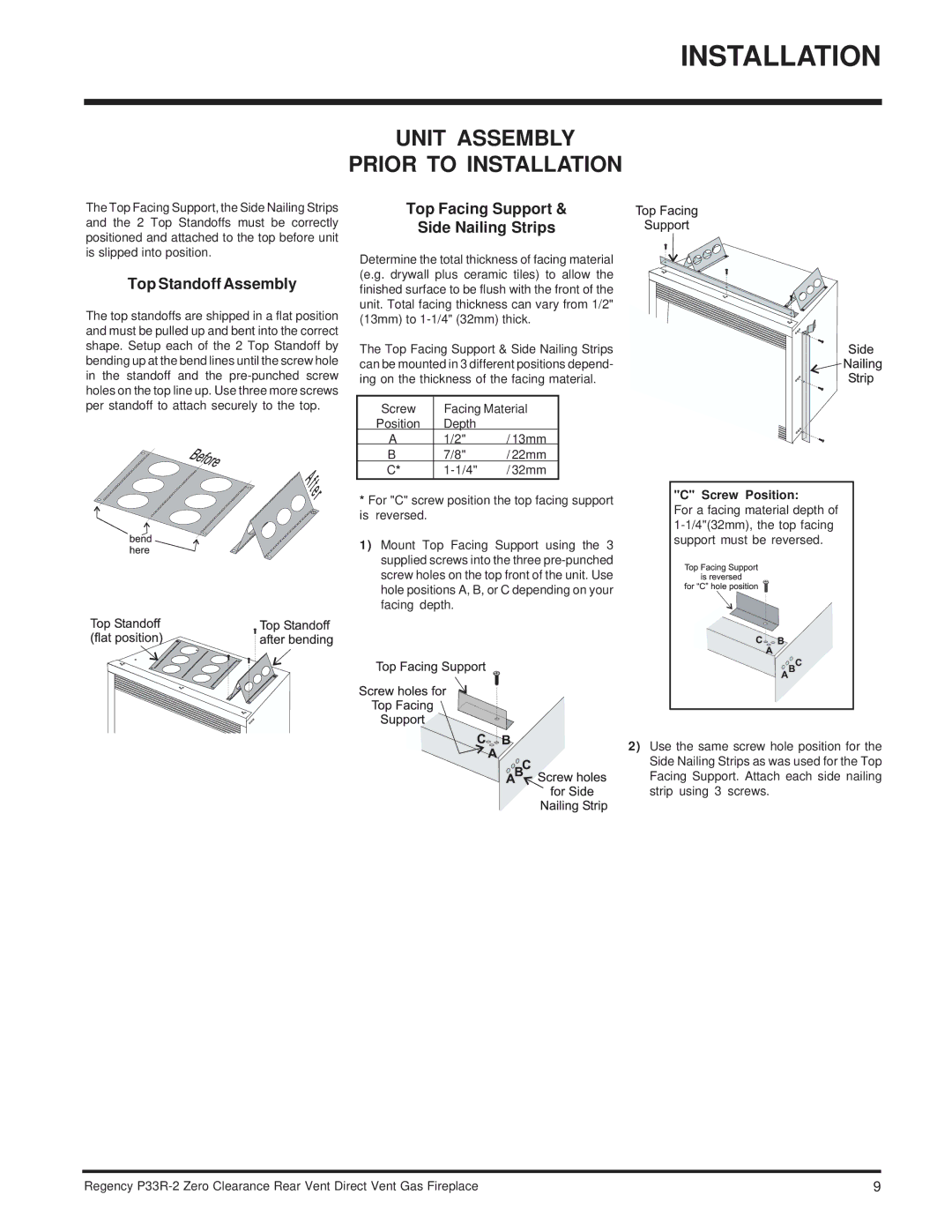

The Top Facing Support, the Side Nailing Strips and the 2 Top Standoffs must be correctly positioned and attached to the top before unit is slipped into position.

Top Standoff Assembly

The top standoffs are shipped in a flat position and must be pulled up and bent into the correct shape. Setup each of the 2 Top Standoff by bending up at the bend lines until the screw hole in the standoff and the

Top Facing Support &

Side Nailing Strips

Determine the total thickness of facing material (e.g. drywall plus ceramic tiles) to allow the finished surface to be flush with the front of the unit. Total facing thickness can vary from 1/2" (13mm) to

The Top Facing Support & Side Nailing Strips can be mounted in 3 different positions depend- ing on the thickness of the facing material.

Screw | Facing Material | |

Position | Depth |

|

A | 1/2" | / 13mm |

B | 7/8" | / 22mm |

C* | / 32mm | |

*For "C" screw position the top facing support is reversed.

1)Mount Top Facing Support using the 3 supplied screws into the three

"C" Screw Position:

For a facing material depth of

2)Use the same screw hole position for the Side Nailing Strips as was used for the Top Facing Support. Attach each side nailing strip using 3 screws.

Regency | 9 |