INSTALLATION

VENTING INTRODUCTION

The

There are 2 vent systems approved for use with the

Note: These flue pipes must not be connected to any other appliance.

The gas appliance and vent system must be vented directly to the outside of the building, and never be attached to a chimney serving a separate solid fuel or gas burning appliance. Each direct vent gas appliance must use it's own separate vent system. Common vent systems are prohibited.

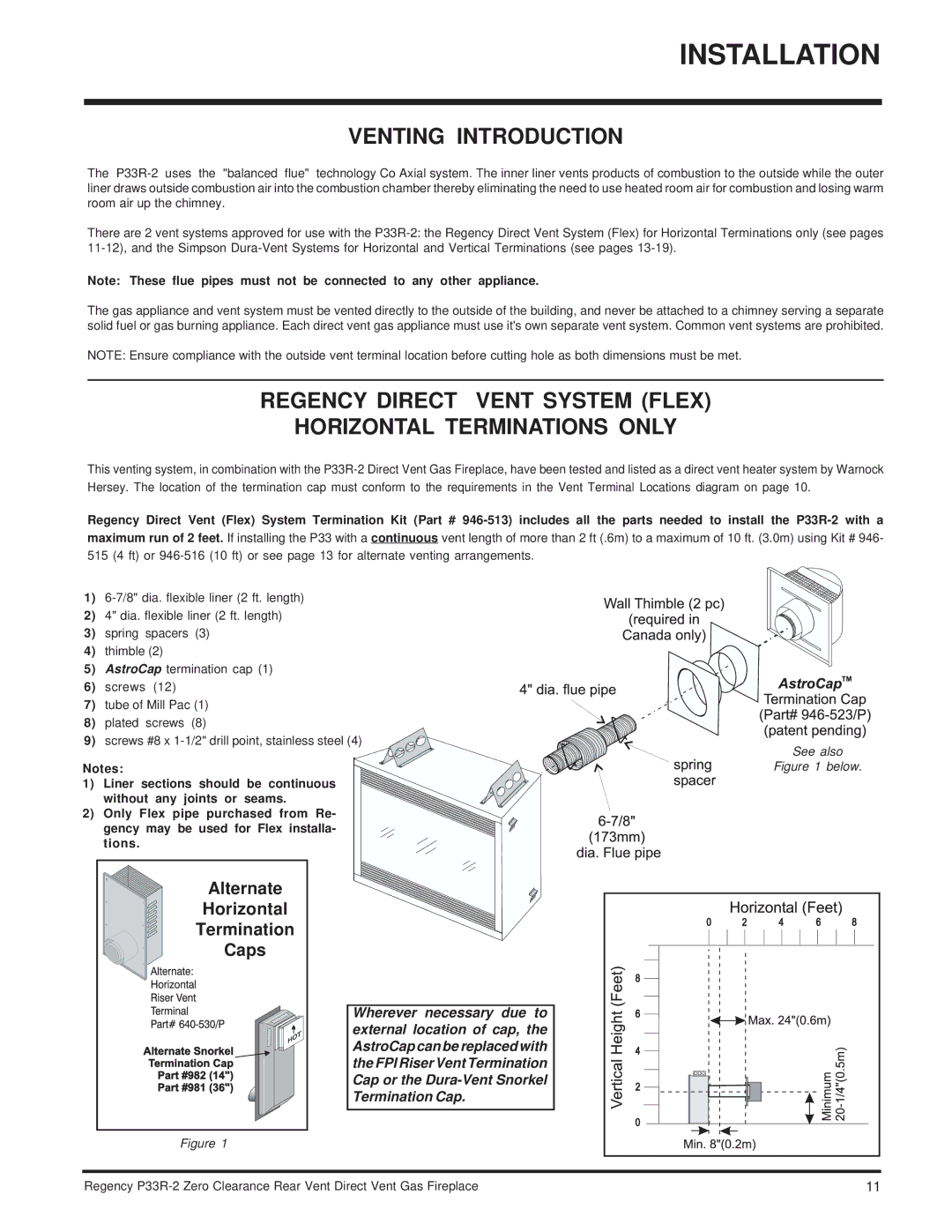

NOTE: Ensure compliance with the outside vent terminal location before cutting hole as both dimensions must be met.

REGENCY DIRECT VENT SYSTEM (FLEX)

HORIZONTAL TERMINATIONS ONLY

This venting system, in combination with the

Hersey. The location of the termination cap must conform to the requirements in the Vent Terminal Locations diagram on page 10.

Regency Direct Vent (Flex) System Termination Kit (Part #

maximum run of 2 feet. If installing the P33 with a continuous vent length of more than 2 ft (.6m) to a maximum of 10 ft. (3.0m) using Kit # 946- 515 (4 ft) or

1)

2)4" dia. flexible liner (2 ft. length)

3)spring spacers (3)

4)thimble (2)

5)AstroCap termination cap (1)

6)screws (12)

7)tube of Mill Pac (1)

8)plated screws (8)

9)screws #8 x

Notes:

1)Liner sections should be continuous without any joints or seams.

2)Only Flex pipe purchased from Re- gency may be used for Flex installa- tions.

See also

Figure 1 below.

Alternate |

|

Horizontal |

|

Termination |

|

Caps |

|

Wherever necessary due to |

|

external location of cap, the |

|

AstroCap can be replaced with |

|

the FPI Riser Vent Termination |

|

Cap or the |

|

Termination Cap. |

|

Figure 1 |

|

Regency | 11 |