|

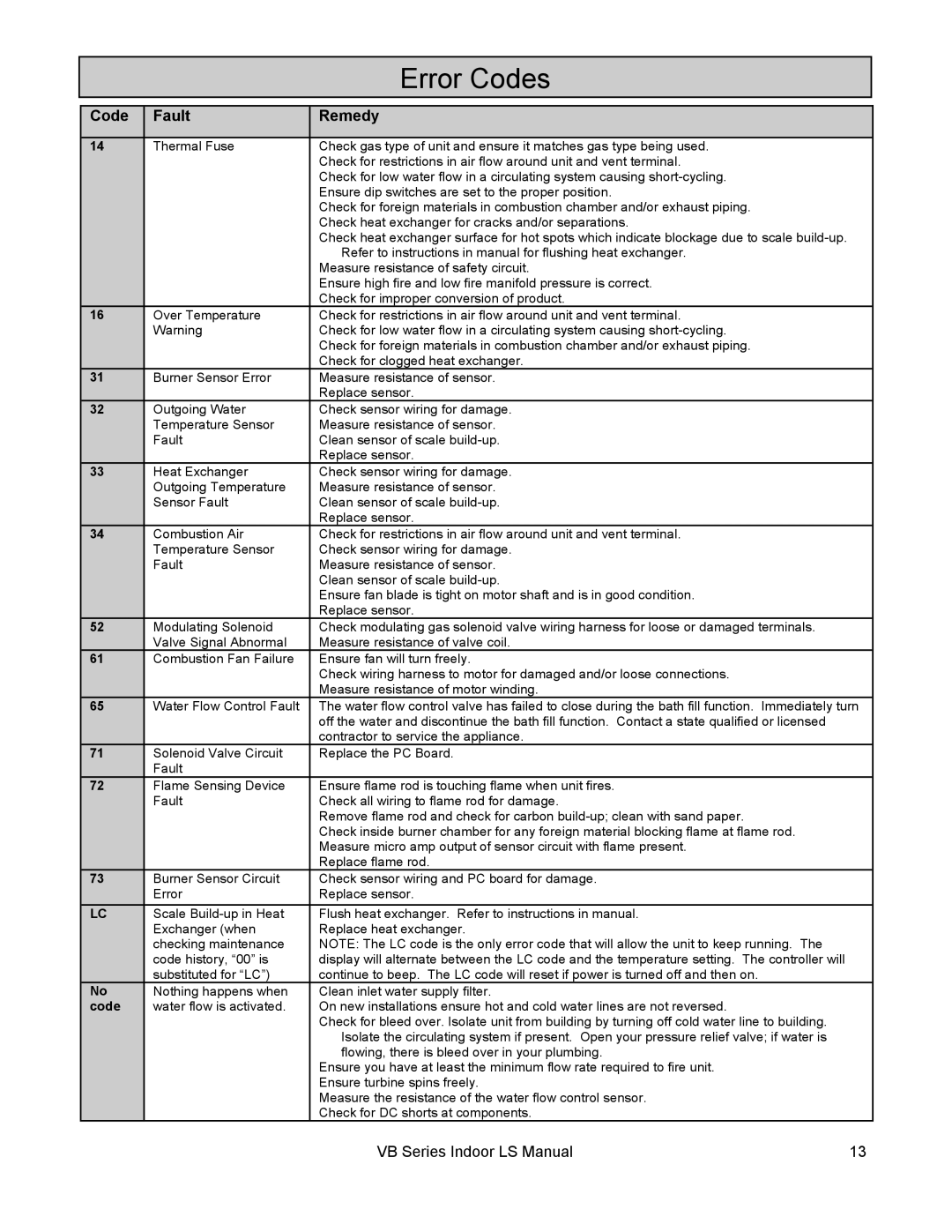

| Error Codes |

|

|

|

|

|

Code | Fault | Remedy |

|

|

|

|

|

14 | Thermal Fuse | Check gas type of unit and ensure it matches gas type being used. |

|

|

| Check for restrictions in air flow around unit and vent terminal. |

|

|

| Check for low water flow in a circulating system causing |

|

|

| Ensure dip switches are set to the proper position. |

|

|

| Check for foreign materials in combustion chamber and/or exhaust piping. |

|

|

| Check heat exchanger for cracks and/or separations. |

|

|

| Check heat exchanger surface for hot spots which indicate blockage due to scale |

|

|

| Refer to instructions in manual for flushing heat exchanger. |

|

|

| Measure resistance of safety circuit. |

|

|

| Ensure high fire and low fire manifold pressure is correct. |

|

|

| Check for improper conversion of product. |

|

16 | Over Temperature | Check for restrictions in air flow around unit and vent terminal. |

|

| Warning | Check for low water flow in a circulating system causing |

|

|

| Check for foreign materials in combustion chamber and/or exhaust piping. |

|

|

| Check for clogged heat exchanger. |

|

31 | Burner Sensor Error | Measure resistance of sensor. |

|

|

| Replace sensor. |

|

32 | Outgoing Water | Check sensor wiring for damage. |

|

| Temperature Sensor | Measure resistance of sensor. |

|

| Fault | Clean sensor of scale |

|

|

| Replace sensor. |

|

33 | Heat Exchanger | Check sensor wiring for damage. |

|

| Outgoing Temperature | Measure resistance of sensor. |

|

| Sensor Fault | Clean sensor of scale |

|

|

| Replace sensor. |

|

34 | Combustion Air | Check for restrictions in air flow around unit and vent terminal. |

|

| Temperature Sensor | Check sensor wiring for damage. |

|

| Fault | Measure resistance of sensor. |

|

|

| Clean sensor of scale |

|

|

| Ensure fan blade is tight on motor shaft and is in good condition. |

|

|

| Replace sensor. |

|

52 | Modulating Solenoid | Check modulating gas solenoid valve wiring harness for loose or damaged terminals. |

|

| Valve Signal Abnormal | Measure resistance of valve coil. |

|

61 | Combustion Fan Failure | Ensure fan will turn freely. |

|

|

| Check wiring harness to motor for damaged and/or loose connections. |

|

|

| Measure resistance of motor winding. |

|

65 | Water Flow Control Fault | The water flow control valve has failed to close during the bath fill function. Immediately turn | |

|

| off the water and discontinue the bath fill function. Contact a state qualified or licensed |

|

|

| contractor to service the appliance. |

|

71 | Solenoid Valve Circuit | Replace the PC Board. |

|

| Fault |

|

|

72 | Flame Sensing Device | Ensure flame rod is touching flame when unit fires. |

|

| Fault | Check all wiring to flame rod for damage. |

|

|

| Remove flame rod and check for carbon |

|

|

| Check inside burner chamber for any foreign material blocking flame at flame rod. |

|

|

| Measure micro amp output of sensor circuit with flame present. |

|

|

| Replace flame rod. |

|

73 | Burner Sensor Circuit | Check sensor wiring and PC board for damage. |

|

| Error | Replace sensor. |

|

LC | Scale | Flush heat exchanger. Refer to instructions in manual. |

|

| Exchanger (when | Replace heat exchanger. |

|

| checking maintenance | NOTE: The LC code is the only error code that will allow the unit to keep running. The |

|

| code history, “00” is | display will alternate between the LC code and the temperature setting. The controller will |

|

| substituted for “LC”) | continue to beep. The LC code will reset if power is turned off and then on. |

|

No | Nothing happens when | Clean inlet water supply filter. |

|

code | water flow is activated. | On new installations ensure hot and cold water lines are not reversed. |

|

|

| Check for bleed over. Isolate unit from building by turning off cold water line to building. |

|

|

| Isolate the circulating system if present. Open your pressure relief valve; if water is |

|

|

| flowing, there is bleed over in your plumbing. |

|

|

| Ensure you have at least the minimum flow rate required to fire unit. |

|

|

| Ensure turbine spins freely. |

|

|

| Measure the resistance of the water flow control sensor. |

|

|

| Check for DC shorts at components. |

|

|

| VB Series Indoor LS Manual | 13 |