Alignment and Adjustmens

4.9 Periodic Defective Image

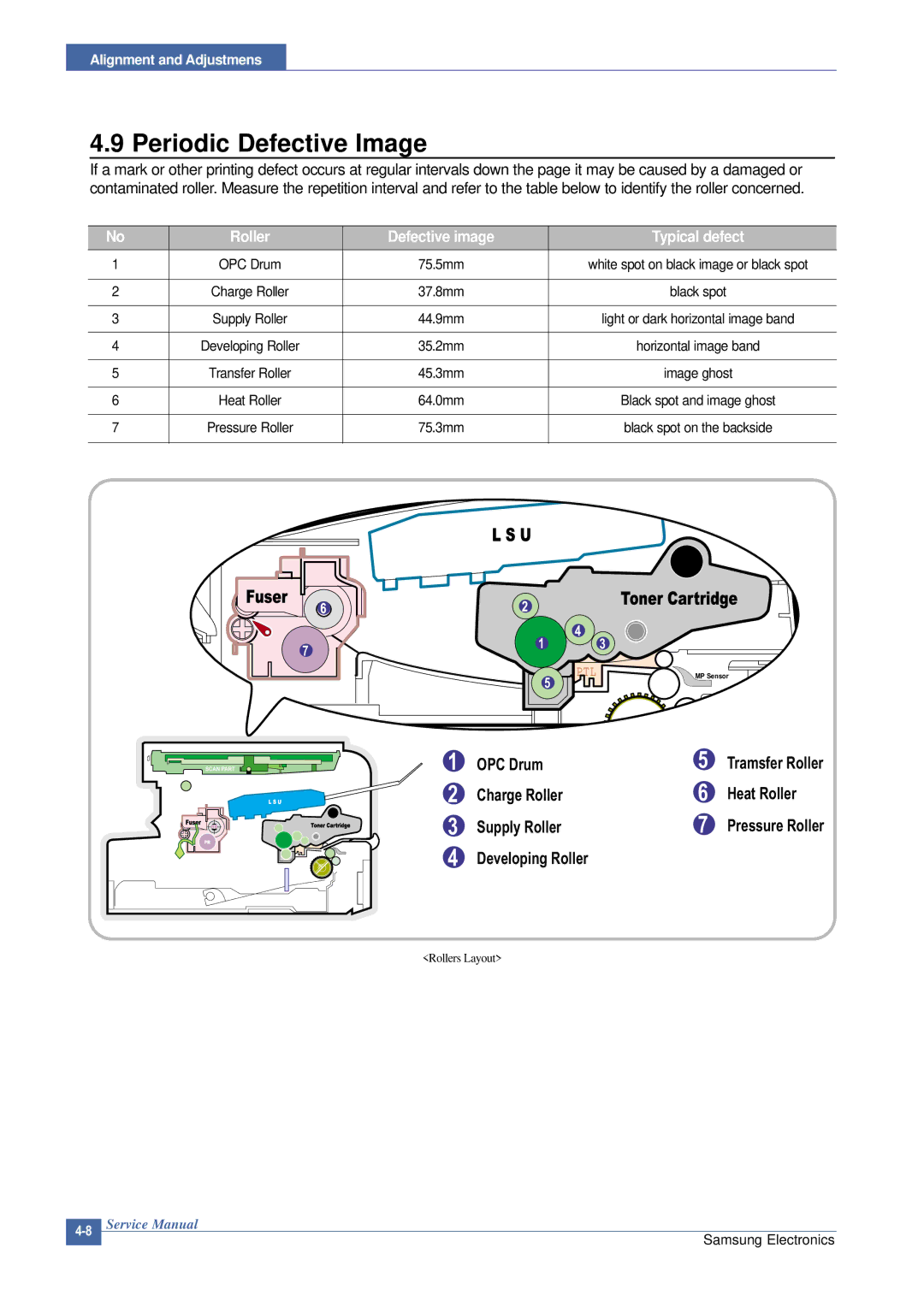

If a mark or other printing defect occurs at regular intervals down the page it may be caused by a damaged or contaminated roller. Measure the repetition interval and refer to the table below to identify the roller concerned.

No

1

2

3

4

5

6

7

Roller | Defective image | Typical defect |

OPC Drum | 75.5mm | white spot on black image or black spot |

Charge Roller | 37.8mm | black spot |

Supply Roller | 44.9mm | light or dark horizontal image band |

Developing Roller | 35.2mm | horizontal image band |

Transfer Roller | 45.3mm | image ghost |

Heat Roller | 64.0mm | Black spot and image ghost |

Pressure Roller | 75.3mm | black spot on the backside |

|

|

|

7 | 1 | 3 |

|

| |

|

| PTL |

|

| 5 |

MP Sensor

SCAN PART

1

2

3

4

OPC Drum

Charge Roller

Supply Roller

Developing Roller

5

6

7

Tramsfer Roller

Heat Roller

Pressure Roller

<Rollers Layout>

| Service Manual |

| Samsung Electronics |