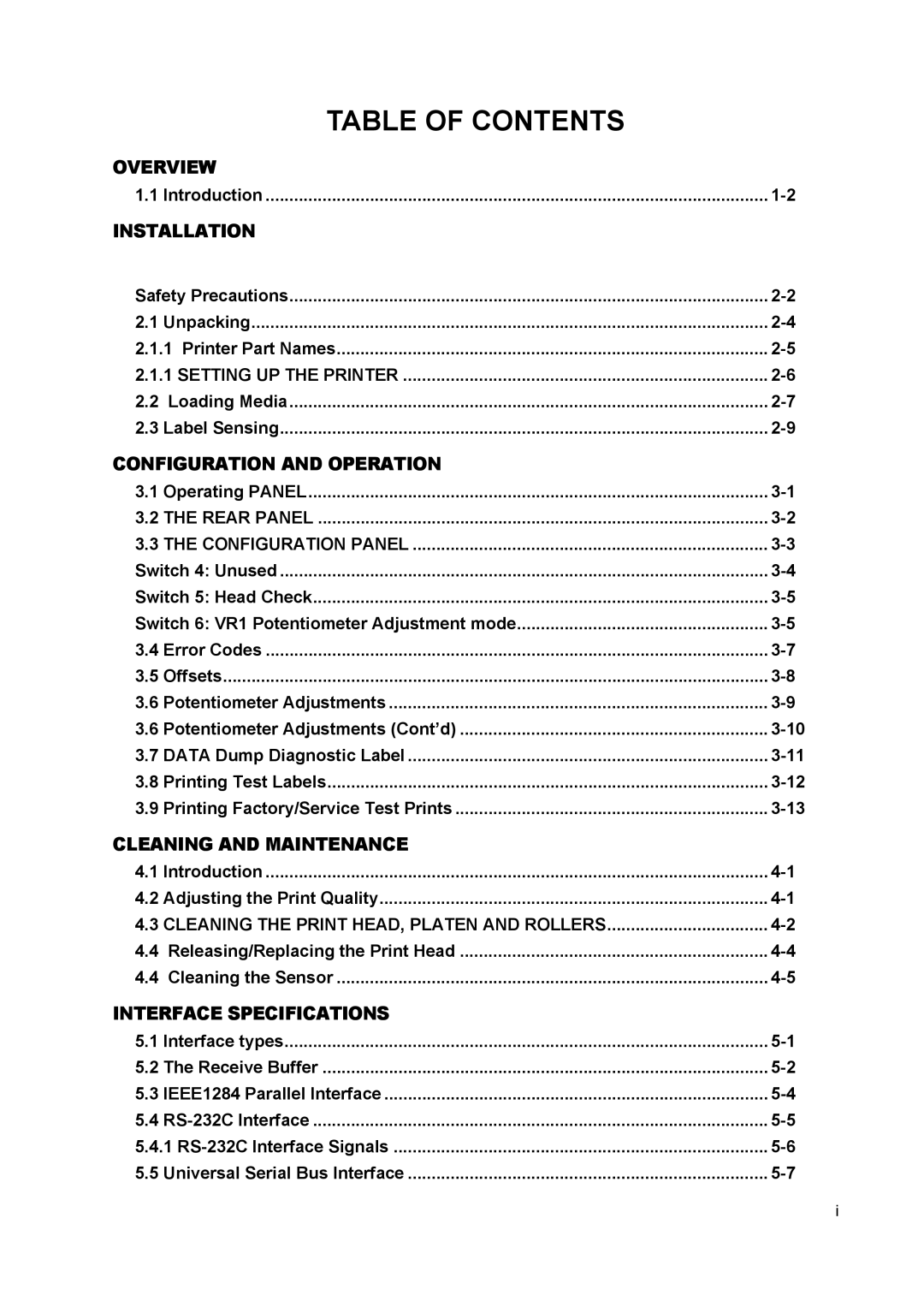

| TABLE OF CONTENTS |

|

OVERVIEW |

| |

1.1 | Introduction | |

INSTALLATION |

| |

Safety Precautions | ||

2.1 | Unpacking | |

2.1.1 Printer Part Names | ||

2.1.1 SETTING UP THE PRINTER | ||

2.2 | Loading Media | |

2.3 | Label Sensing | |

CONFIGURATION AND OPERATION |

| |

3.1 | Operating PANEL | |

3.2 THE REAR PANEL | ||

3.3 THE CONFIGURATION PANEL | ||

Switch 4: Unused | ||

Switch 5: Head Check | ||

Switch 6: VR1 Potentiometer Adjustment mode | ||

3.4 | Error Codes | |

3.5 | Offsets | |

3.6 | Potentiometer Adjustments | |

3.6 | Potentiometer Adjustments (Cont’d) | |

3.7 | DATA Dump Diagnostic Label | |

3.8 | Printing Test Labels | |

3.9 | Printing Factory/Service Test Prints | |

CLEANING AND MAINTENANCE |

| |

4.1 | Introduction | |

4.2 | Adjusting the Print Quality | |

4.3 CLEANING THE PRINT HEAD, PLATEN AND ROLLERS | ||

4.4 | Releasing/Replacing the Print Head | |

4.4 | Cleaning the Sensor | |

INTERFACE SPECIFICATIONS |

| |

5.1 | Interface types | |

5.2 | The Receive Buffer | |

5.3 | IEEE1284 Parallel Interface | |

5.4 | ||

5.4.1 | ||

5.5 | Universal Serial Bus Interface | |

i