SECTION 4: CLEANING AND MAINTENANCE

4.4 CLEANING THE SENSOR

The gap sensor is used to control the positioning of the label. It is a transmissive

So when dust, dirt or other foreign matter interferes with the light path of the sensor, erratic label positioning occurs. The sensor should thus be cleaned regularly, after every two rolls of labels.

1.Turn the printer OFF and remove the power cable.

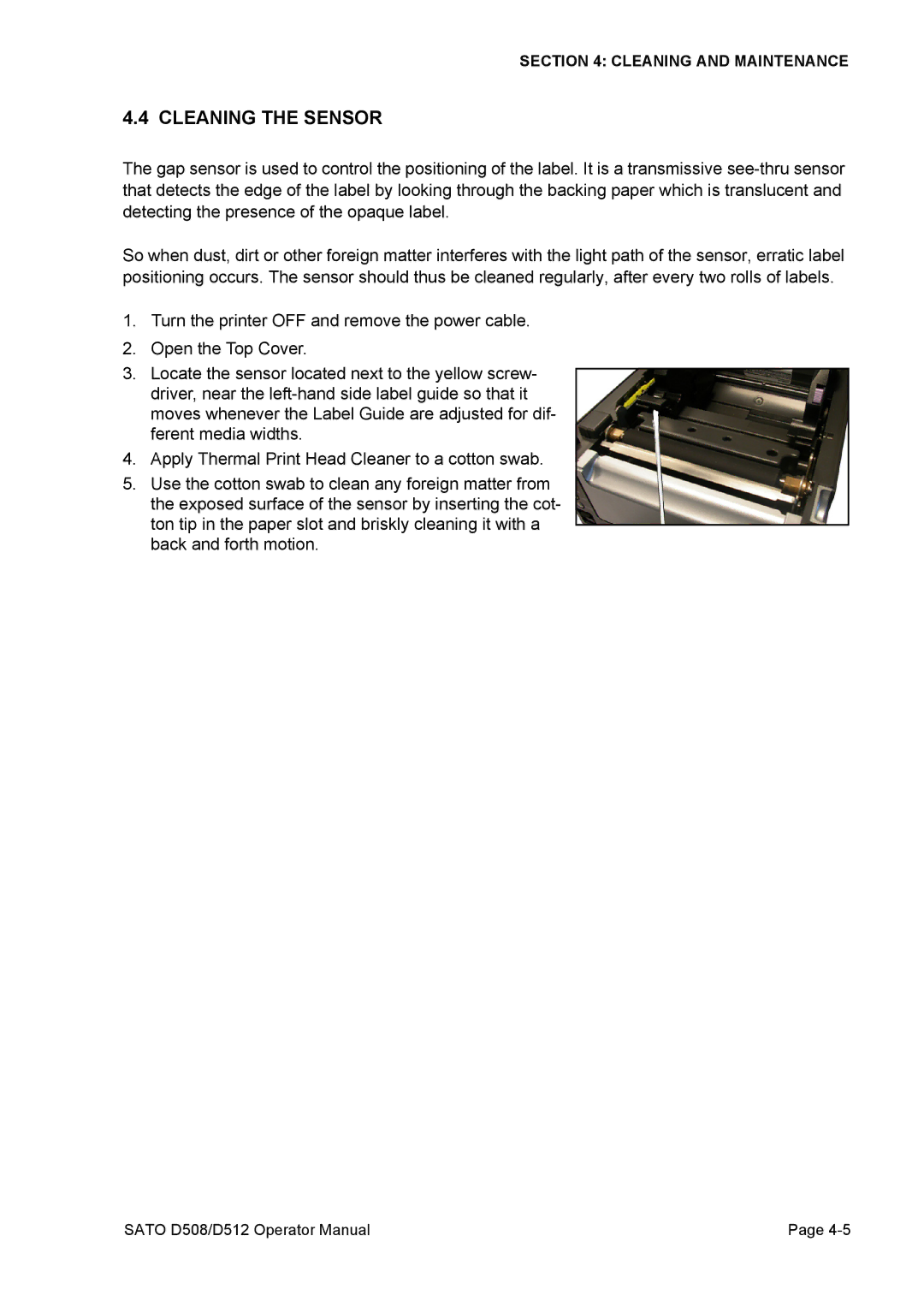

2.Open the Top Cover.

3.Locate the sensor located next to the yellow screw- driver, near the

4.Apply Thermal Print Head Cleaner to a cotton swab.

5.Use the cotton swab to clean any foreign matter from the exposed surface of the sensor by inserting the cot- ton tip in the paper slot and briskly cleaning it with a back and forth motion.

SATO D508/D512 Operator Manual | Page |