assembly

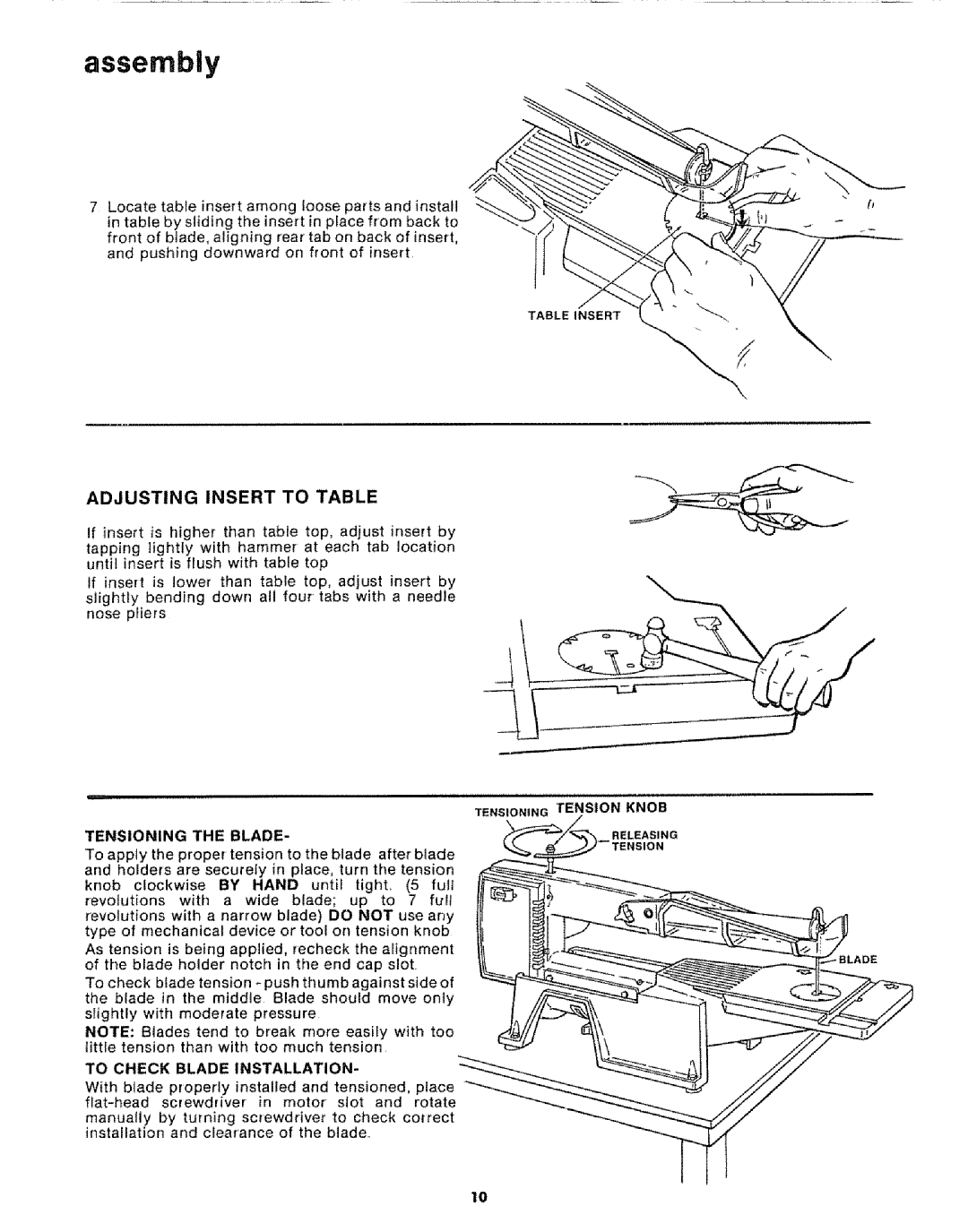

7 Locate table insert among loose parts and install in table by sliding the insert in place from back to front of blade, aligning rear tab on back of insert, and pushing downward on front of insert

TABLEINSERT

ADJUSTING INSERT TO TABLE

if insert is higher than table top, adjust insert by tapping lightly with hammer at each tab location until insert is flush with table top

If insert is lower than table top, adjust insert by slightly bending down all four tabs with a needle nose pliers

TENSIONING TENSION KNOB

TENSIONING THE BLADE-

To apply the proper tension to the blade after blade and holders are securely in place, turn the tension knob clockwise BY HAND until tight, (5 full revolutions with a wide blade; up to 7 full revolutions with a narrow blade) DO NOT use any type of mechanical device or tool on tension knob

As tension is being applied, recheck the aNgnment of the blade holder notch in the end cap slot

To check blade tension _ push thumb against sideof the blade in the middle Blade should move only slightly with moderate pressure

NOTE: Blades tend to break more easily with too little tension than with too much tension

TO CHECK BLADE INSTALLATION-

With blade properly installed and tensioned, place

manually by turning screwdriver to check correct installation and clearance of the blade,

t'l

BLADE

10