basic scronHsaw operation

NOTE: Make certain set screws in blade holders are tight prior to each use of the scroll saw

WARNING: NEVER OPERATE WITHOUT TABLE INSERT IN PLACE°

This scroll saw accepts a wide variety of blade widths and thicknesses: 5" to 6" length plain end type blades and 5" length pin type blades The blade size (thickness and width) and the number of teeth per inch are determined by the type of material and the smallest radius being cut

NOTE: Use wider blades to achieve straightest cuts

A scroll saw is basically a "curve cutting" machine It can also be used for

Using the proper blade for the material and thickness being cut will help the operator to follow pattern lines. (Use wider blades to achieve the straightest cuts ) Blade teeth should always point down

When a blade is dull, or when insufficient blade

tension is being used, the blade may have a tendency to twist or break

To minimize blade breakage and to produce more accurate results, be sure the blade is not forced into the workpiece. Too much pressure should not be applied on the wood as it is fed into the blade. Steady, even pressure will produce more uniform, cleaner cutting with less blade breakage.

Loosen blade tension knob when scroll saw is not in use.. Follow procedure to tension blade before use.

The scroll saw has the capability of inside cutting (piercing).

while installing blade through workpiece. Release

tension knob (see BLADE INSTALLATION-

GETTING TO KNOW YOUR SCROLL SAW) Remove blade, and place workpiece on table with drilled hole aligned over blade slot in insert. Replace blade, sliding it through drilled hole and insert slot. Reinstall blade in lower and upper blade holders.

Retighten tension knob (see BLADE

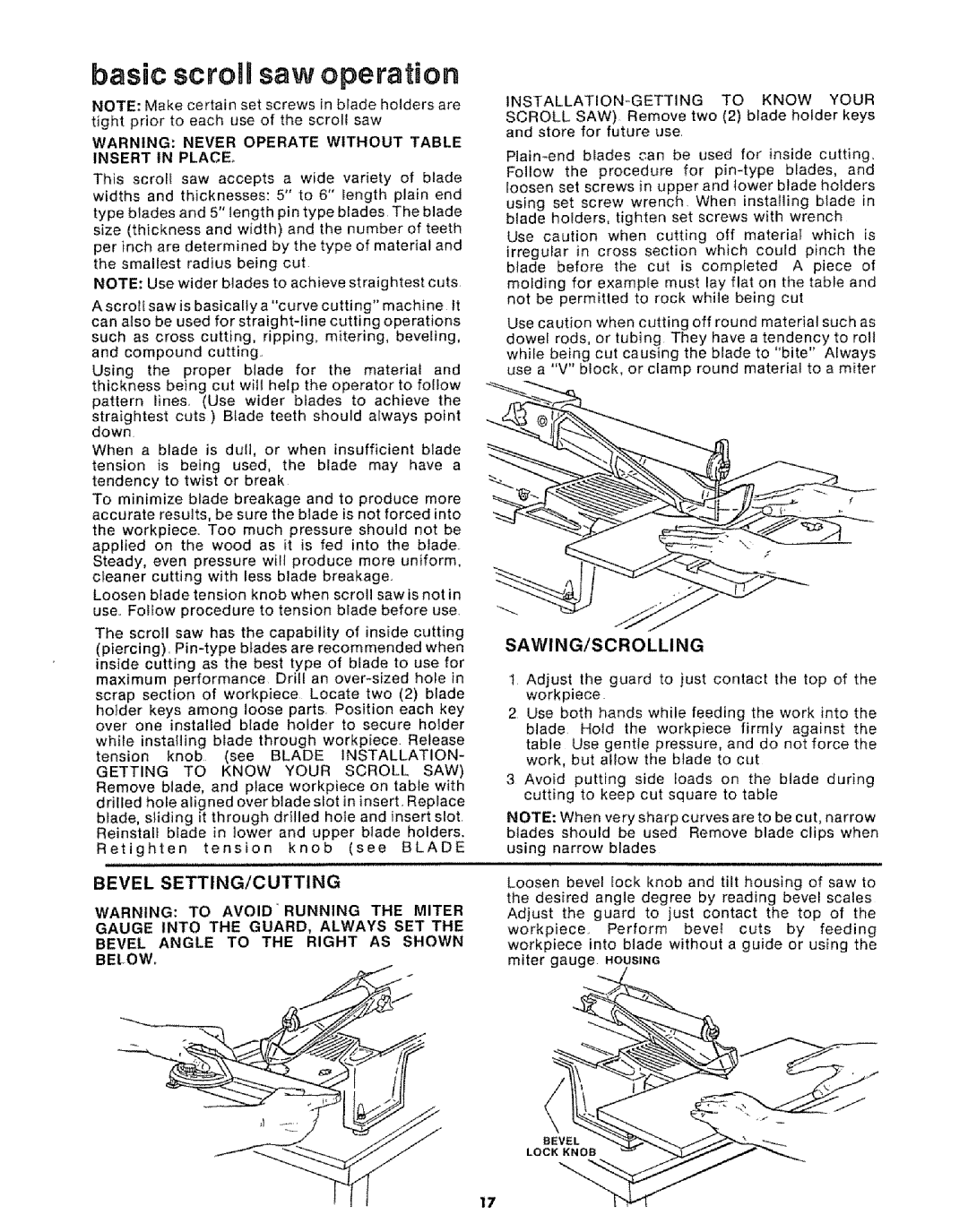

BEVEL SETTING/CUTTING

WARNING: TO AVOID _ RUNNING THE MITER GAUGE INTO THE GUARD, ALWAYS SET THE

BEVEL ANGLE TO THE RIGHT AS SHOWN BELOW,

SCROLL SAW) Remove two (2) blade holder keys and store for future use

using set screw wrench When installing blade in blade holders, tighten set screws with wrench

Use caution when cutting off material which is irregular in cross section which could pinch the blade before the cut is completed A piece of molding for example must lay flat on the table and not be permitted to rock while being cut

Use caution when cutting off round material such as dowel rods, or tubing They have a tendency to roll while being cut causing the blade to "bite" Always use a "V" block, or clamp round material to a miter

SAWING/SCROLLING

1 Adjust the guard to just contact the top of the workpiece

2 Use both hands while feeding the work into the blade Hold the workpiece firmly against the table Use gentle pressure, and do not force the work, but allow the blade to cut

3 Avoid putting side loads on the blade during cutting to keep cut square to table

NOTE: When very sharp curves are to be cut, narrow blades should be used Remove blade clips when

using narrow blades

Loosen bevel lock knob and tilt housing of saw to the desired angle degree by reading bevel scales Adjust the guard to just contact the top of the

workpiece Perform bevel cuts by feeding workpiece into blade without a guide or using the

miter gauge HOUSING

BEVEL

LOCK KNOB

17