OPERATION

OPERATION

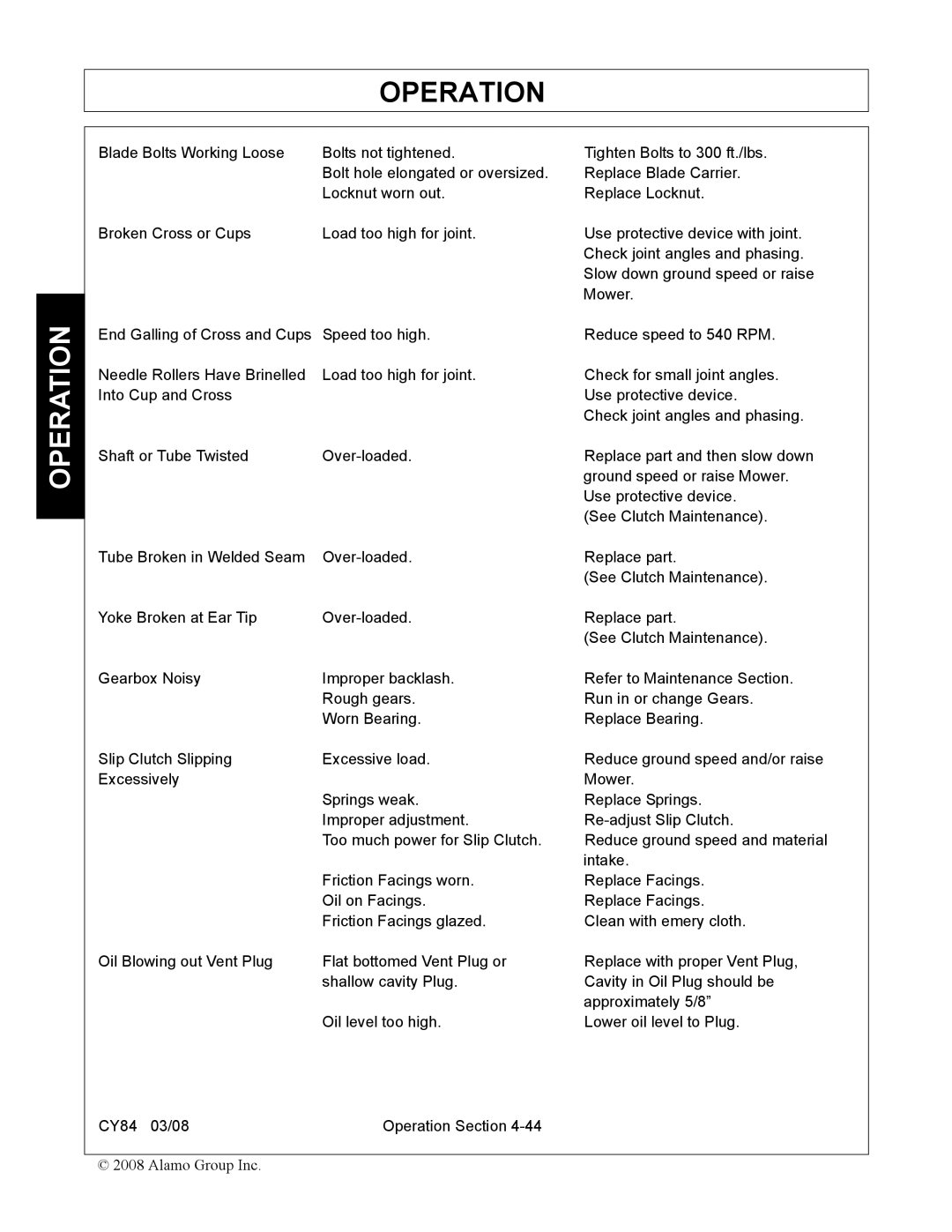

Blade Bolts Working Loose | Bolts not tightened. | Tighten Bolts to 300 ft./lbs. |

| Bolt hole elongated or oversized. | Replace Blade Carrier. |

| Locknut worn out. | Replace Locknut. |

Broken Cross or Cups | Load too high for joint. | Use protective device with joint. |

|

| Check joint angles and phasing. |

|

| Slow down ground speed or raise |

|

| Mower. |

End Galling of Cross and Cups | Speed too high. | Reduce speed to 540 RPM. |

Needle Rollers Have Brinelled | Load too high for joint. | Check for small joint angles. |

Into Cup and Cross |

| Use protective device. |

|

| Check joint angles and phasing. |

Shaft or Tube Twisted | Replace part and then slow down | |

|

| ground speed or raise Mower. |

|

| Use protective device. |

|

| (See Clutch Maintenance). |

Tube Broken in Welded Seam | Replace part. | |

|

| (See Clutch Maintenance). |

Yoke Broken at Ear Tip | Replace part. | |

|

| (See Clutch Maintenance). |

Gearbox Noisy | Improper backlash. | Refer to Maintenance Section. |

| Rough gears. | Run in or change Gears. |

| Worn Bearing. | Replace Bearing. |

Slip Clutch Slipping | Excessive load. | Reduce ground speed and/or raise |

Excessively |

| Mower. |

| Springs weak. | Replace Springs. |

| Improper adjustment. | |

| Too much power for Slip Clutch. | Reduce ground speed and material |

|

| intake. |

| Friction Facings worn. | Replace Facings. |

| Oil on Facings. | Replace Facings. |

| Friction Facings glazed. | Clean with emery cloth. |

Oil Blowing out Vent Plug | Flat bottomed Vent Plug or | Replace with proper Vent Plug, |

| shallow cavity Plug. | Cavity in Oil Plug should be |

|

| approximately 5/8” |

| Oil level too high. | Lower oil level to Plug. |

CY84 03/08 | Operation Section |

© 2008 Alamo Group Inc.