MAINTENANCE

Driveline Lubrication

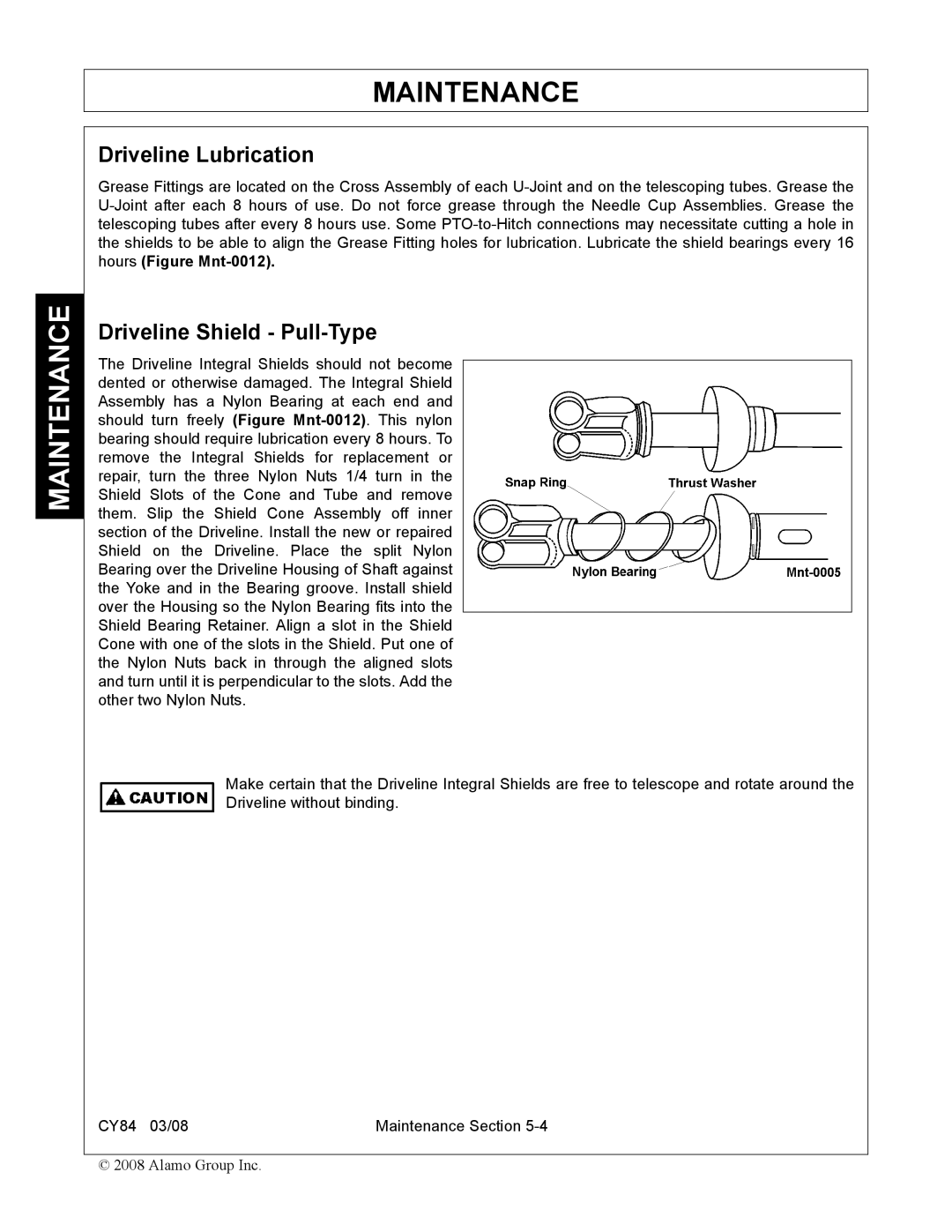

Grease Fittings are located on the Cross Assembly of each U-Joint and on the telescoping tubes. Grease the U-Joint after each 8 hours of use. Do not force grease through the Needle Cup Assemblies. Grease the telescoping tubes after every 8 hours use. Some PTO-to-Hitch connections may necessitate cutting a hole in the shields to be able to align the Grease Fitting holes for lubrication. Lubricate the shield bearings every 16 hours (Figure Mnt-0012).

Driveline Shield - Pull-Type

The Driveline Integral Shields should not become dented or otherwise damaged. The Integral Shield Assembly has a Nylon Bearing at each end and should turn freely (Figure Mnt-0012). This nylon bearing should require lubrication every 8 hours. To remove the Integral Shields for replacement or repair, turn the three Nylon Nuts 1/4 turn in the Shield Slots of the Cone and Tube and remove them. Slip the Shield Cone Assembly off inner section of the Driveline. Install the new or repaired Shield on the Driveline. Place the split Nylon Bearing over the Driveline Housing of Shaft against the Yoke and in the Bearing groove. Install shield over the Housing so the Nylon Bearing fits into the Shield Bearing Retainer. Align a slot in the Shield Cone with one of the slots in the Shield. Put one of the Nylon Nuts back in through the aligned slots and turn until it is perpendicular to the slots. Add the other two Nylon Nuts.

Make certain that the Driveline Integral Shields are free to telescope and rotate around the Driveline without binding.

CY84 03/08 | Maintenance Section 5-4 |

© 2008 Alamo Group Inc.