MAINTENANCE

MAINTENANCE

Slip Clutch

Avoid overheating of the Slip Clutch by too long or too frequent slipping, as this can damage the friction plates and limiter parts. When checking Slip Clutch for overheating, DO NOT touch with hand. Slip Clutch could be extremely hot and cause severe burn.

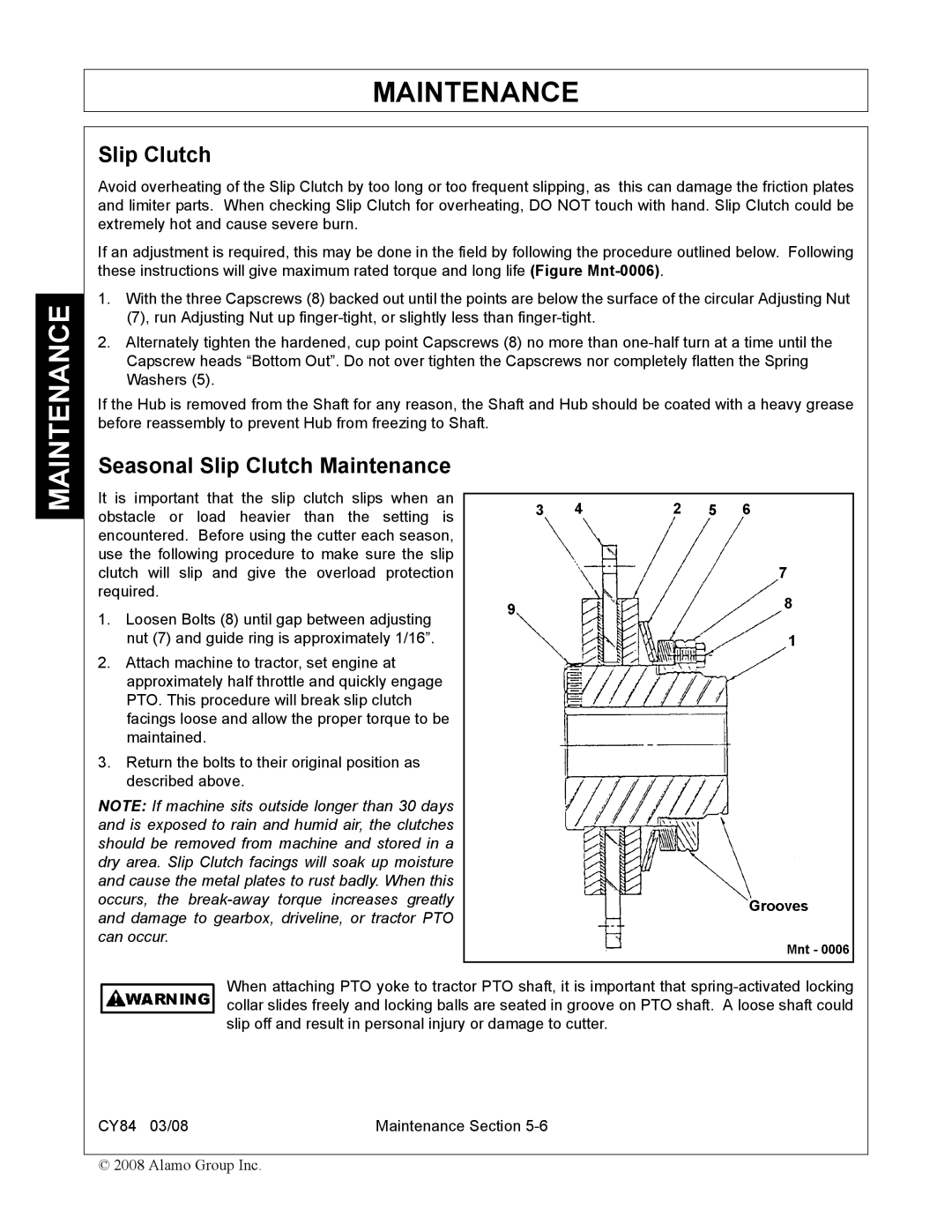

If an adjustment is required, this may be done in the field by following the procedure outlined below. Following these instructions will give maximum rated torque and long life (Figure

1.With the three Capscrews (8) backed out until the points are below the surface of the circular Adjusting Nut (7), run Adjusting Nut up

2.Alternately tighten the hardened, cup point Capscrews (8) no more than

If the Hub is removed from the Shaft for any reason, the Shaft and Hub should be coated with a heavy grease before reassembly to prevent Hub from freezing to Shaft.

Seasonal Slip Clutch Maintenance

It is important that the slip clutch slips when an obstacle or load heavier than the setting is encountered. Before using the cutter each season, use the following procedure to make sure the slip clutch will slip and give the overload protection required.

1.Loosen Bolts (8) until gap between adjusting nut (7) and guide ring is approximately 1/16”.

2.Attach machine to tractor, set engine at approximately half throttle and quickly engage PTO. This procedure will break slip clutch facings loose and allow the proper torque to be maintained.

3.Return the bolts to their original position as described above.

NOTE: If machine sits outside longer than 30 days and is exposed to rain and humid air, the clutches should be removed from machine and stored in a dry area. Slip Clutch facings will soak up moisture and cause the metal plates to rust badly. When this occurs, the

When attaching PTO yoke to tractor PTO shaft, it is important that

CY84 03/08 | Maintenance Section |

© 2008 Alamo Group Inc.