MAINTENANCE

LUBRICATION

Both the gearbox and the cutter bar are lubricated by a seperate oil supply. To fill the cutter bar. Raise the cutter bar up 90 degrees and remove Plug. Add SAE HD90 gear lube or equivalent until oil flows from opening. Reinstall the plug using a pipe thread sealant. (See Figure 4 & 5.)

| Figure 4 | Figure 5 |

|

| |

The following approximate amounts of SAE HD90 gear lube, or equivalent, are required: |

| |

Model DM82 | 2.4 Quarts |

|

Model DM95 | 3.1 Quarts |

|

Model DM112 | 3.8 Quarts |

|

Model DM124 | 4.5 Quarts |

|

Both the gearbox and the cutter bar use a seperate oil supply.

Gearbox: 0.75 Quarts SAE EP90 all models. Check and fill gearbox through top level plug in Figure 4. To Drain gearbox raise bar 90 degrees and remove fill plug.

IMPORTANT: Replace the lube oil after first 10 hours of operation and after every season of use thereafter.

NOTE: Dispose of used oil properly.

NOTE: The surface temperature of the discs, cutter bar and gearbox will rise to approximately 175 degrees during operation. This is normal and is not an indication of excessive friction or low oil level.

To drain the oil from the bar, remove Drain Plug. Plug on underside of bar and remove level plug to aid in draining oil.

Figure 6

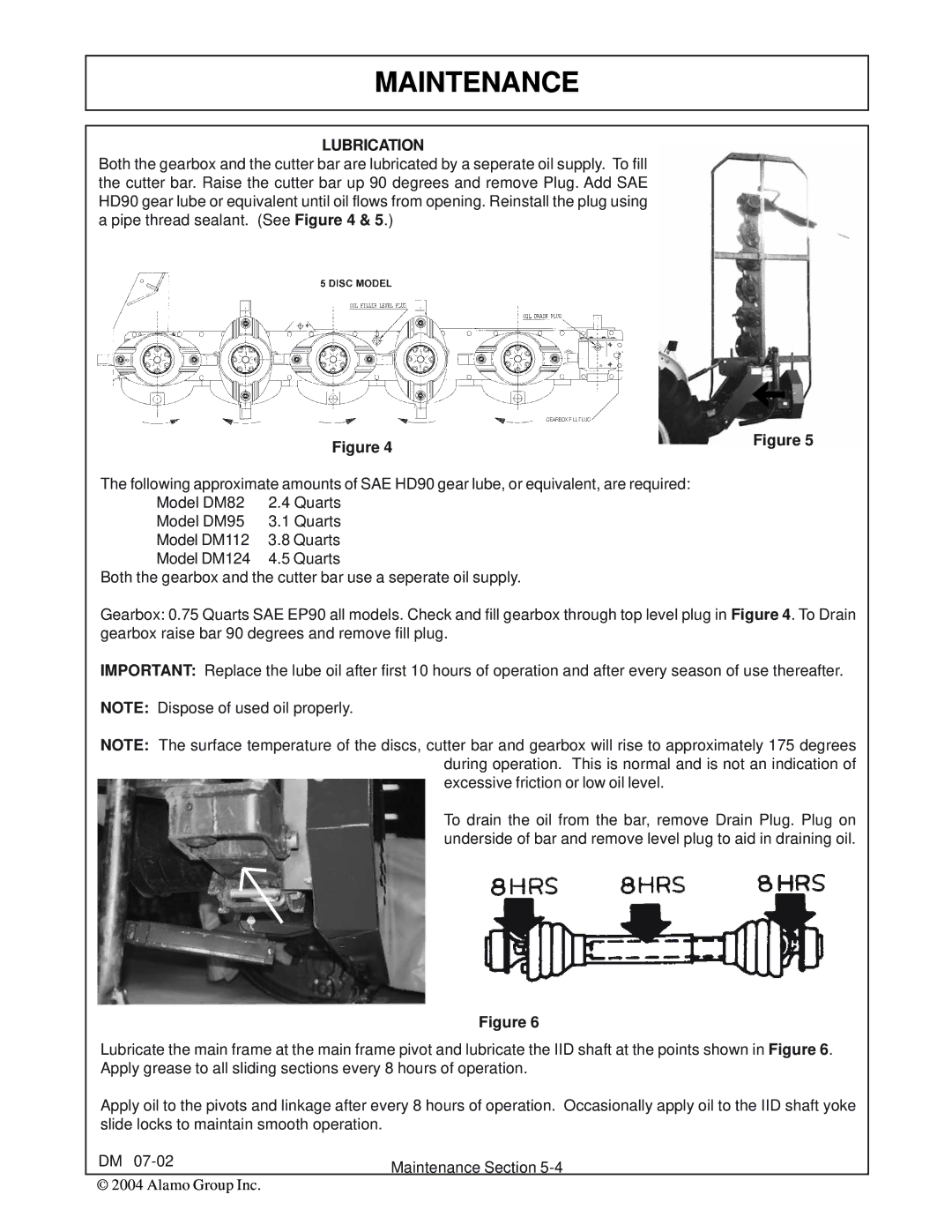

Lubricate the main frame at the main frame pivot and lubricate the IID shaft at the points shown in Figure 6. Apply grease to all sliding sections every 8 hours of operation.

Apply oil to the pivots and linkage after every 8 hours of operation. Occasionally apply oil to the IID shaft yoke slide locks to maintain smooth operation.

DM | Maintenance Section |

|