minal. Otherwise, welding output terminals may burn out by the heat caused by insufficient connections.

zDo not use a cable without a crimping terminal. If you use the cable, the insulation is peeled off partly, to bind to an output terminal, the output terminal may burn out by the heat caused by insufficient connections and also a bare part of the cable may touch the bonnet to short- circuit.

8-4 Duty Cycle

Duty cycle means the welding time ratio for 10 minutes. This equipment is the rated duty cycle is 50%, namely, the welding time is 5 minutes or less. Be sure to take 5 minutes recess after 5 minutes welding.

<Caution>

zThe equipment may be damaged due to overheat, if welding more than 5 minutes succes- sively or short time recess after the welding.

8-5 Welding

![]() Caution : Suffocation from welding fume

Caution : Suffocation from welding fume

zBe sure to wear a fume proof mask in operation, because welding fume contains poisonous gas and dust. Pay attention to the airflow direction and sufficient ventilation also in order to prevent from inhaling the fume.

![]() Caution : Injuries to eyes and skin

Caution : Injuries to eyes and skin

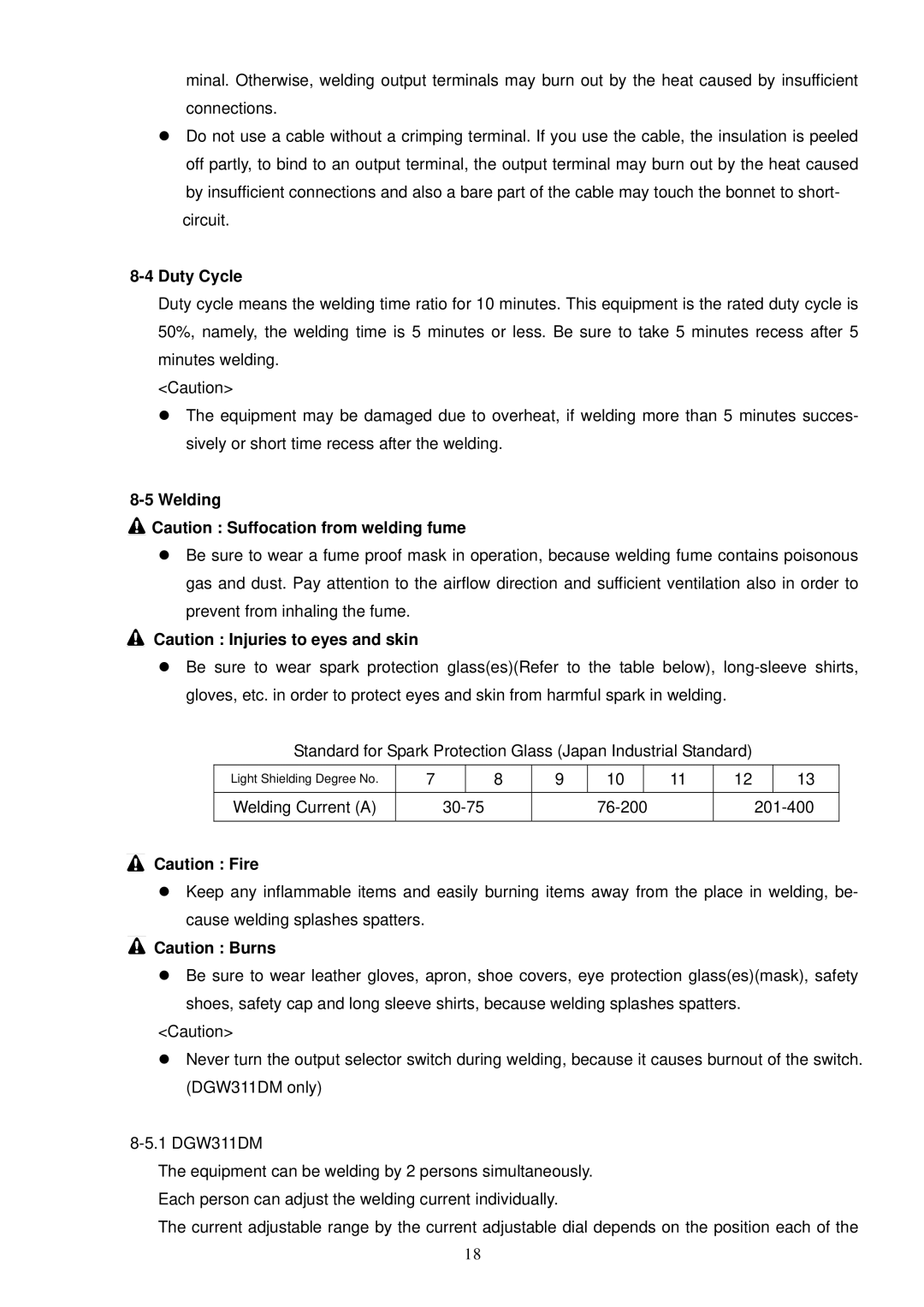

zBe sure to wear spark protection glass(es)(Refer to the table below),

Standard for Spark Protection Glass (Japan Industrial Standard)

Light Shielding Degree No. | 7 |

| 8 | 9 | 10 |

| 11 | 12 |

| 13 |

|

|

|

|

|

|

|

|

|

|

|

Welding Current (A) |

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

![]() Caution : Fire

Caution : Fire

zKeep any inflammable items and easily burning items away from the place in welding, be- cause welding splashes spatters.

![]() Caution : Burns

Caution : Burns

zBe sure to wear leather gloves, apron, shoe covers, eye protection glass(es)(mask), safety shoes, safety cap and long sleeve shirts, because welding splashes spatters.

<Caution>

zNever turn the output selector switch during welding, because it causes burnout of the switch. (DGW311DM only)

The equipment can be welding by 2 persons simultaneously. Each person can adjust the welding current individually.

The current adjustable range by the current adjustable dial depends on the position each of the

18