Safety Rules

equipment can result in serious injury, damage to equipment, and voiding of your warranty.

TRANSPORTING AND STORAGE

•If you must travel across rock, gravel, or other

•Never lift the unit using the fuel tank, vacuum intake areas, or covers for support. If the unit must be lifted for vehicular transportation, always use at least two people, and always grip the unit securely using the units rigid steel frame. The power drive feature should only be used for loading by experienced operators using ramps designed to ensure that the unit stays properly positioned on the ramps while the Chipper Vacuum is moving.

•If the unit must remain tilted for transportation, con- sult the engine manual for required preparation, Normally, engine fuel and oil must be drained to pre- vent dangerous fuel leakage, and unwanted transfer of the sump oil into the cylinder head area.

•Always refill the oil sump with the recommended oil before attempting to use the unit again after it has been drained for transportation.

•Always observe safe refueling and fuel handling practices when refueling the unit after transportation or storage.

•Always follow the engine manual instructions for

storage preparations before storing the unit for pro- longed periods.

•Always follow the engine manual instructions for proper

SERVICE AND MAINTENANCE

•Always follow recommended engine and Chipper Vacuum procedures when performing required ser- vice and maintenance on the unit.

•Use only

•Never attempt to make major repairs on this unit unless you have been properly trained and certified to work on

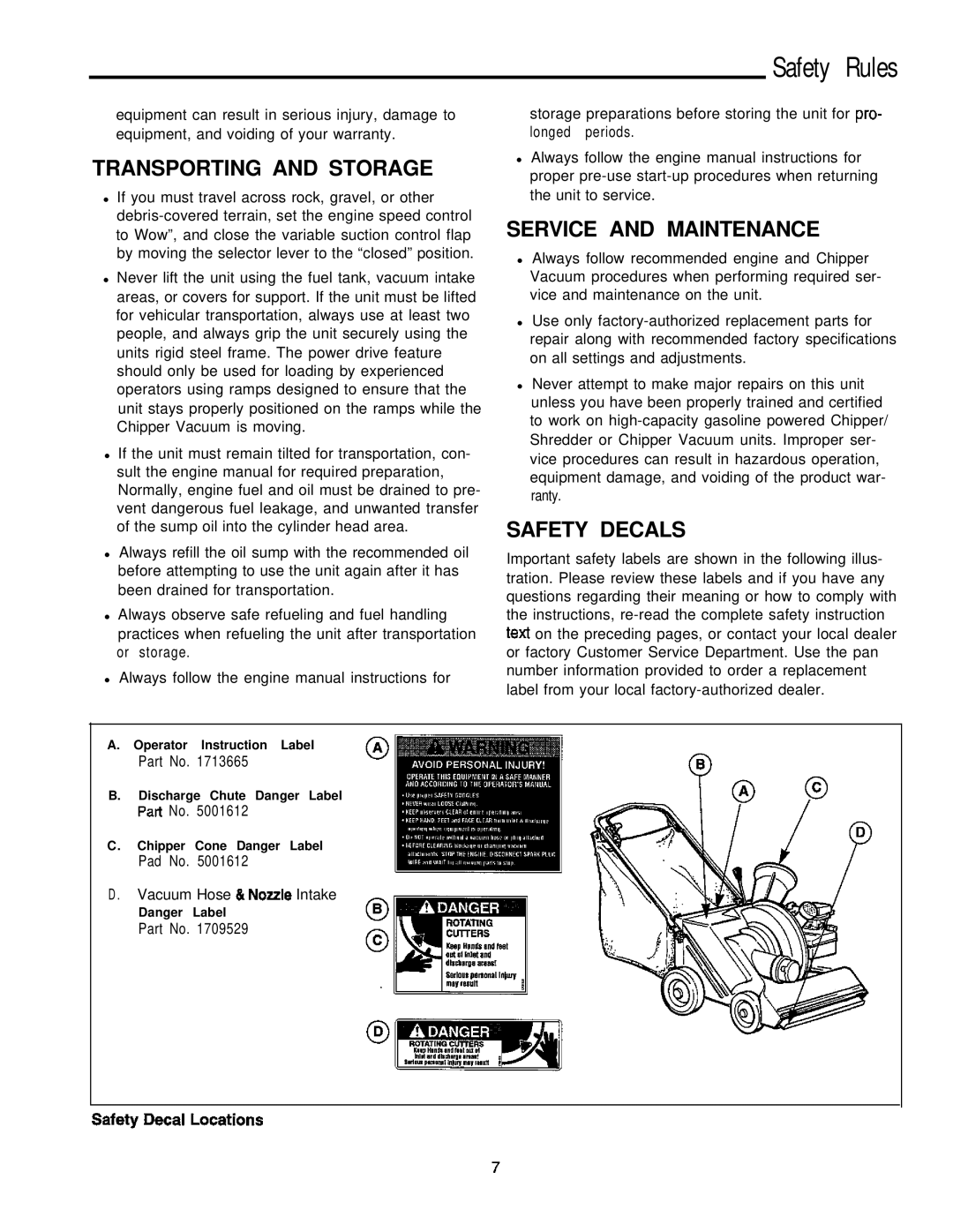

SAFETY DECALS

Important safety labels are shown in the following illus- tration. Please review these labels and if you have any questions regarding their meaning or how to comply with the instructions,

A. Operator Instruction Label

Part No. 1713665

B.Discharge Chute Danger Label

Part No. 5001612

C.Chipper Cone Danger Label

Pad No. 5001612

D . Vacuum Hose & Nozzle Intake

Danger Label

Part No. 1709529