Operation

Drive Speed Selector

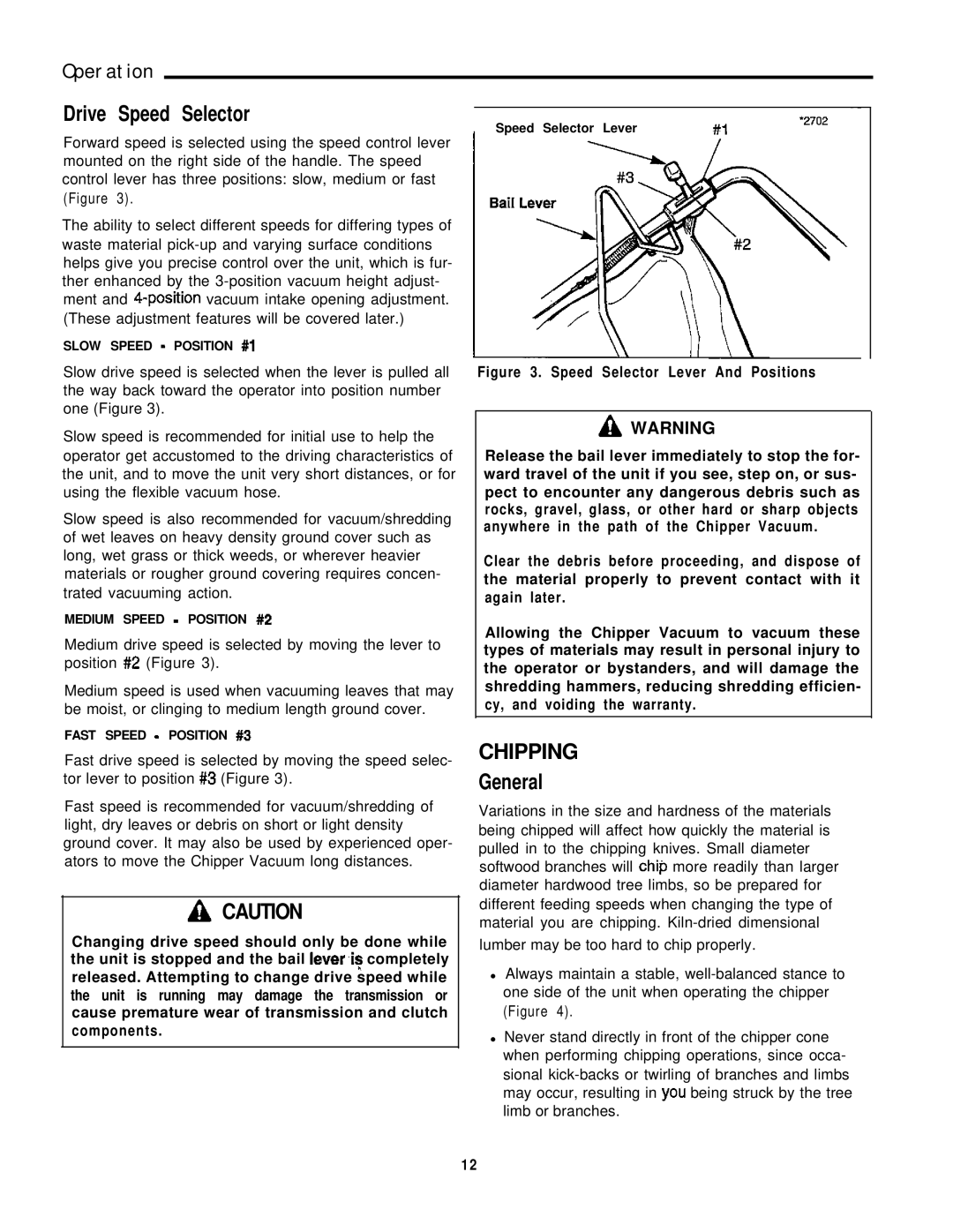

Forward speed is selected using the speed control lever mounted on the right side of the handle. The speed control lever has three positions: slow, medium or fast (Figure 3).

The ability to select different speeds for differing types of waste material

SLOW SPEED ![]() - POSITION #l

- POSITION #l

Slow drive speed is selected when the lever is pulled all the way back toward the operator into position number one (Figure 3).

Slow speed is recommended for initial use to help the operator get accustomed to the driving characteristics of the unit, and to move the unit very short distances, or for using the flexible vacuum hose.

Slow speed is also recommended for vacuum/shredding of wet leaves on heavy density ground cover such as long, wet grass or thick weeds, or wherever heavier materials or rougher ground covering requires concen- trated vacuuming action.

MEDIUM SPEED ![]()

Medium drive speed is selected by moving the lever to position #2 (Figure 3).

Medium speed is used when vacuuming leaves that may be moist, or clinging to medium length ground cover.

FAST SPEED ![]()

Fast drive speed is selected by moving the speed selec- tor lever to position #3 (Figure 3).

Fast speed is recommended for vacuum/shredding of light, dry leaves or debris on short or light density ground cover. It may also be used by experienced oper- ators to move the Chipper Vacuum long distances.

A CAUTION

Changing drive speed should only be done while the unit is stopped and the bail lever,+ completely released. Attempting to change drive speed while the unit is running may damage the transmission or cause premature wear of transmission and clutch components.

Speed Selector Lever

Figure 3. Speed Selector Lever And Positions

AWARNING

Release the bail lever immediately to stop the for- ward travel of the unit if you see, step on, or sus- pect to encounter any dangerous debris such as rocks, gravel, glass, or other hard or sharp objects anywhere in the path of the Chipper Vacuum.

Clear the debris before proceeding, and dispose of the material properly to prevent contact with it again later.

Allowing the Chipper Vacuum to vacuum these types of materials may result in personal injury to the operator or bystanders, and will damage the shredding hammers, reducing shredding efficien- cy, and voiding the warranty.

CHIPPING

General

Variations in the size and hardness of the materials being chipped will affect how quickly the material is pulled in to the chipping knives. Small diameter softwood branches will chip more readily than larger diameter hardwood tree limbs, so be prepared for different feeding speeds when changing the type of material you are chipping.

lumber may be too hard to chip properly.

•Always maintain a stable,

•Never stand directly in front of the chipper cone when performing chipping operations, since occa- sional

12