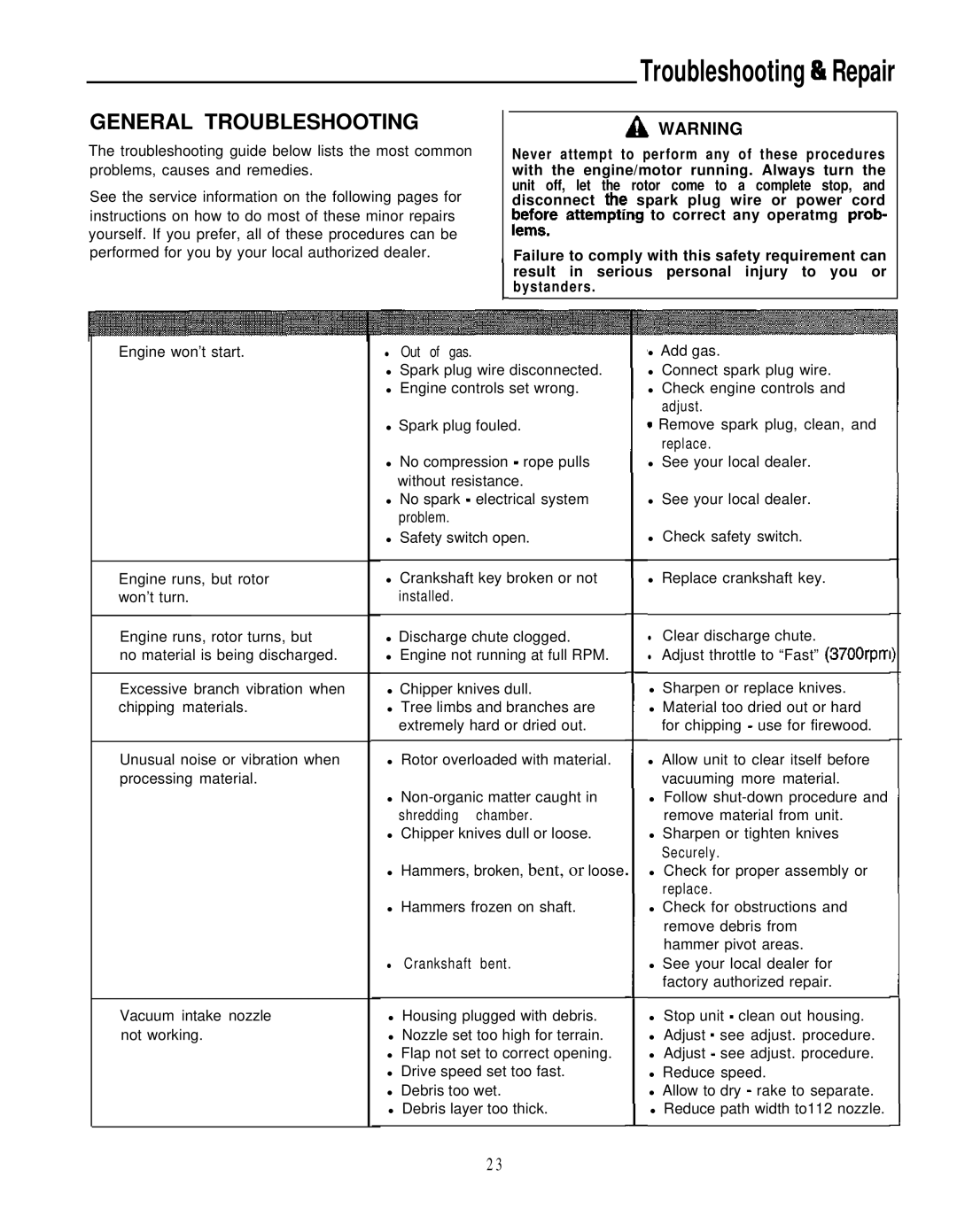

GENERAL TROUBLESHOOTING

The troubleshooting guide below lists the most common problems, causes and remedies.

See the service information on the following pages for instructions on how to do most of these minor repairs yourself. If you prefer, all of these procedures can be performed for you by your local authorized dealer.

Troubleshooting& Repair

Repair

AWARNING

Never attempt to perform any of these procedures with the engine/motor running. Always turn the unit off, let the rotor come to a complete stop, and disconnect the spark plug wire or power cord Ezsre attemptmg to correct any operatmg prob-

Failure to comply with this safety requirement can result in serious personal injury to you or bystanders.

Engine won’t start. |

| • | Out of gas. |

|

|

| • Spark plug wire disconnected. | ||

|

| • Engine controls set wrong. | ||

|

| • | Spark plug fouled. | |

|

| • No compression - rope pulls | ||

|

|

| without resistance. | |

|

| • No spark - electrical system | ||

|

|

| problem. |

|

|

| • | Safety switch open. | |

|

|

|

| |

Engine runs, but rotor |

| • | Crankshaft key broken or not | |

won’t turn. |

|

| installed. |

|

|

|

|

| |

Engine runs, rotor turns, but |

| • | Discharge chute clogged. | |

no material is being discharged. |

| • | Engine not running at full RPM. | |

|

|

|

| |

Excessive branch vibration when |

| • | Chipper knives dull. | |

chipping materials. |

| • | Tree limbs and branches are | |

|

|

| extremely hard or dried out. | |

|

|

|

| |

Unusual noise or vibration when |

| • | Rotor overloaded with material. | |

processing material. |

| • | ||

|

| |||

|

|

| shredding | chamber. |

|

| • Chipper knives dull or loose. | ||

|

| • Hammers, broken, bent, or loose | ||

|

| • Hammers frozen on shaft. | ||

|

| • | Crankshaft | bent. |

|

|

|

| |

Vacuum intake nozzle |

| • | Housing plugged with debris. | |

not working. |

| • | Nozzle set too high for terrain. | |

|

| • Flap not set to correct opening. | ||

|

| • Drive speed set too fast. | ||

|

| • | Debris too wet. | |

|

| • Debris layer too thick. | ||

|

|

|

|

|

•Add gas.

•Connect spark plug wire.

•Check engine controls and

adjust.

* Remove spark plug, clean, and replace.

•See your local dealer.

•See your local dealer.

•Check safety switch.

•Replace crankshaft key.

•Clear discharge chute.

•Adjust throttle to “Fast” (3700rplr

•Sharpen or replace knives.

•Material too dried out or hard for chipping - use for firewood.

•Allow unit to clear itself before

vacuuming more material.

•Follow

•Sharpen or tighten knives Securely.

•Check for proper assembly or replace.

•Check for obstructions and remove debris from hammer pivot areas.

•See your local dealer for factory authorized repair.

•Stop unit - clean out housing.

•Adjust - see adjust. procedure.

•Adjust - see adjust. procedure.

•Reduce speed.

•Allow to dry - rake to separate.

•Reduce path width to112 nozzle.

2 3