12.0 Troubleshooting | 102 |

12.6Yaw Bearing

The yaw bearing allows the wind turbine to align itself with the wind. When the blades turn, the turbine should yaw into the proper position with the rotor facing downwind from the rest of the machine. If the wind turbine does not yaw correctly with respect to the wind, the yaw bearing should be greased and visually inspected. It should also be checked to see whether it is level; any necessary adjustments should be made via the anchor bolts at the tower base.

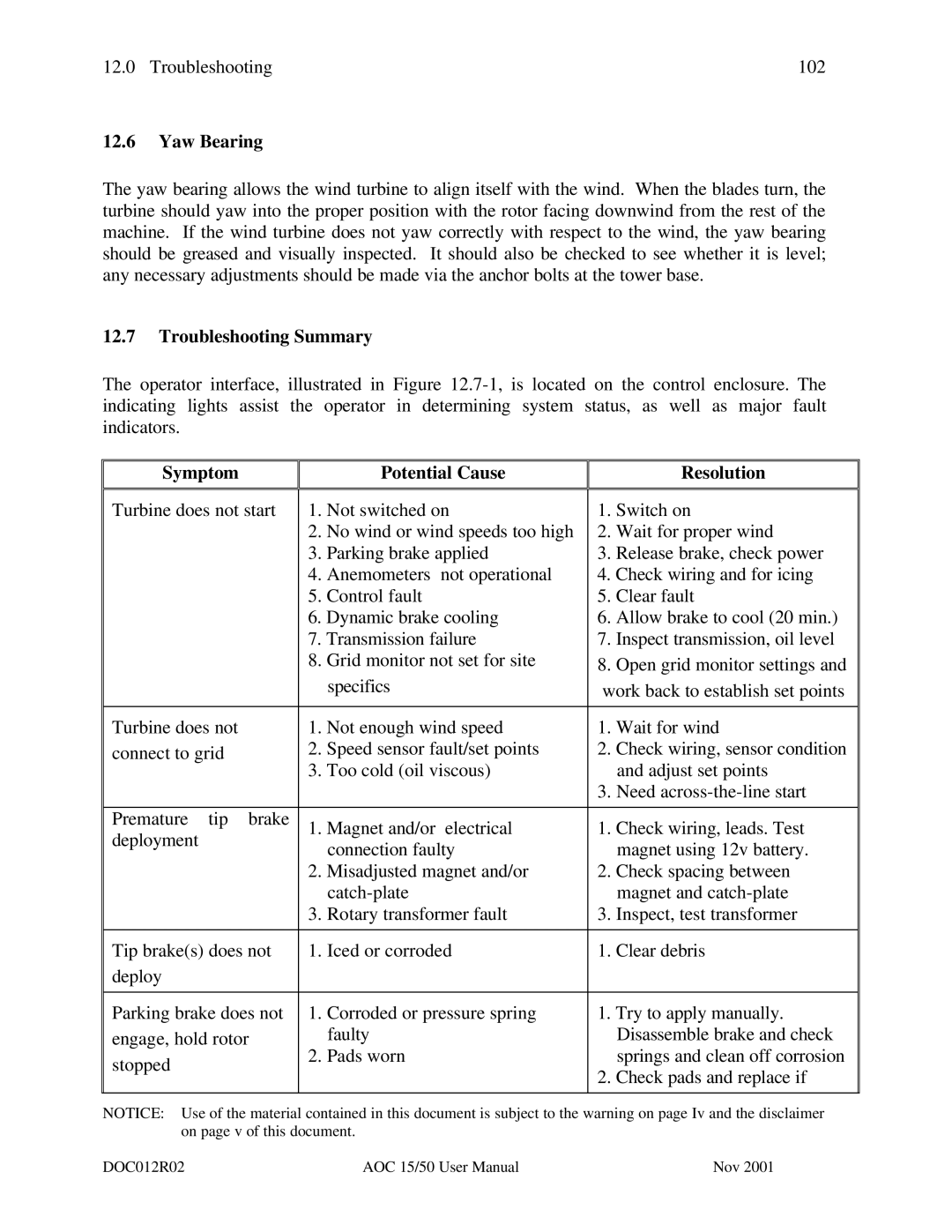

12.7Troubleshooting Summary

The operator interface, illustrated in Figure

Symptom

Potential Cause

Resolution

Turbine does not start | 1. Not switched on | 1. | Switch on | ||

| 2. | No wind or wind speeds too high | 2. | Wait for proper wind | |

| 3. | Parking brake applied | 3. | Release brake, check power | |

| 4. | Anemometers not operational | 4. | Check wiring and for icing | |

| 5. | Control fault | 5. | Clear fault | |

| 6. | Dynamic brake cooling | 6. | Allow brake to cool (20 min.) | |

| 7. | Transmission failure | 7. | Inspect transmission, oil level | |

| 8. | Grid monitor not set for site | 8. | Open grid monitor settings and | |

|

| specifics | work back to establish set points | ||

|

|

|

| ||

Turbine does not | 1. Not enough wind speed | 1. | Wait for wind | ||

connect to grid | 2. Speed sensor fault/set points | 2. | Check wiring, sensor condition | ||

| 3. | Too cold (oil viscous) |

| and adjust set points | |

|

|

| 3. | Need | |

|

|

|

|

| |

Premature tip brake | 1. | Magnet and/or electrical | 1. | Check wiring, leads. Test | |

deployment | |||||

| connection faulty |

| magnet using 12v battery. | ||

|

|

| |||

| 2. | Misadjusted magnet and/or | 2. | Check spacing between | |

|

|

| magnet and | ||

| 3. | Rotary transformer fault | 3. | Inspect, test transformer | |

|

|

|

| ||

Tip brake(s) does not | 1. Iced or corroded | 1. | Clear debris | ||

deploy |

|

|

|

| |

|

|

|

| ||

Parking brake does not | 1. Corroded or pressure spring | 1. | Try to apply manually. | ||

engage, hold rotor |

| faulty |

| Disassemble brake and check | |

stopped | 2. Pads worn |

| springs and clean off corrosion | ||

|

| 2. | Check pads and replace if | ||

|

|

| |||

|

|

|

|

| |

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer on page v of this document.

DOC012R02 | AOC 15/50 User Manual | Nov 2001 |