12.0 Troubleshooting |

|

|

| 103 |

|

|

|

|

|

|

|

|

| necessary |

|

|

|

|

|

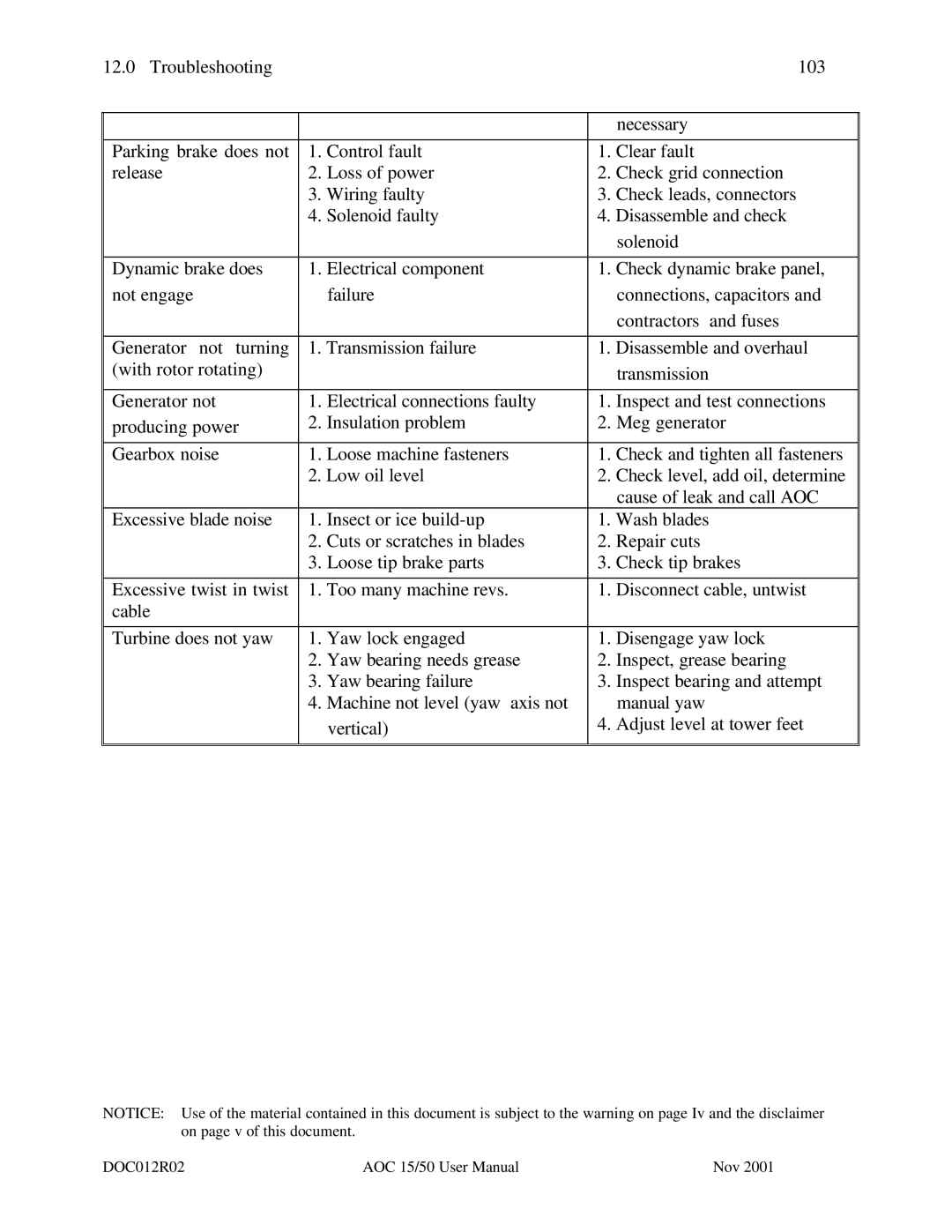

Parking brake does not | 1. | Control fault | 1. | Clear fault |

release | 2. | Loss of power | 2. | Check grid connection |

| 3. Wiring faulty | 3. | Check leads, connectors | |

| 4. | Solenoid faulty | 4. | Disassemble and check |

|

|

|

| solenoid |

|

|

|

|

|

Dynamic brake does | 1. | Electrical component | 1. | Check dynamic brake panel, |

not engage |

| failure |

| connections, capacitors and |

|

|

|

| contractors and fuses |

|

|

|

|

|

Generator not turning | 1. | Transmission failure | 1. | Disassemble and overhaul |

(with rotor rotating) |

|

|

| transmission |

|

|

|

| |

Generator not | 1. Electrical connections faulty | 1. | Inspect and test connections | |

producing power | 2. | Insulation problem | 2. Meg generator | |

|

|

|

|

|

Gearbox noise | 1. | Loose machine fasteners | 1. | Check and tighten all fasteners |

| 2. | Low oil level | 2. | Check level, add oil, determine |

|

|

|

| cause of leak and call AOC |

Excessive blade noise | 1. | Insect or ice | 1. | Wash blades |

| 2. | Cuts or scratches in blades | 2. | Repair cuts |

| 3. | Loose tip brake parts | 3. | Check tip brakes |

|

|

|

|

|

Excessive twist in twist | 1. | Too many machine revs. | 1. | Disconnect cable, untwist |

cable |

|

|

|

|

|

|

|

|

|

Turbine does not yaw | 1. | Yaw lock engaged | 1. | Disengage yaw lock |

| 2. | Yaw bearing needs grease | 2. | Inspect, grease bearing |

| 3. | Yaw bearing failure | 3. | Inspect bearing and attempt |

| 4. | Machine not level (yaw axis not |

| manual yaw |

|

| vertical) | 4. | Adjust level at tower feet |

|

|

|

|

|

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer on page v of this document.

DOC012R02 | AOC 15/50 User Manual | Nov 2001 |