3.0 Safety Guidelines | 15 |

3.3Start-up and Shut-down Safety Procedures

Prior to starting up a wind turbine, the operator should warn any personnel in the area that it will be started and to visually inspect the area to ensure that they are clear of it. In addition, the operator should ensure that there are no visual signs indicating problems with the wind turbine. During a shutdown sequence, no personnel should approach the wind turbine, until it has come to a complete stop.

3.4Securing Machine for Maintenance and Repair

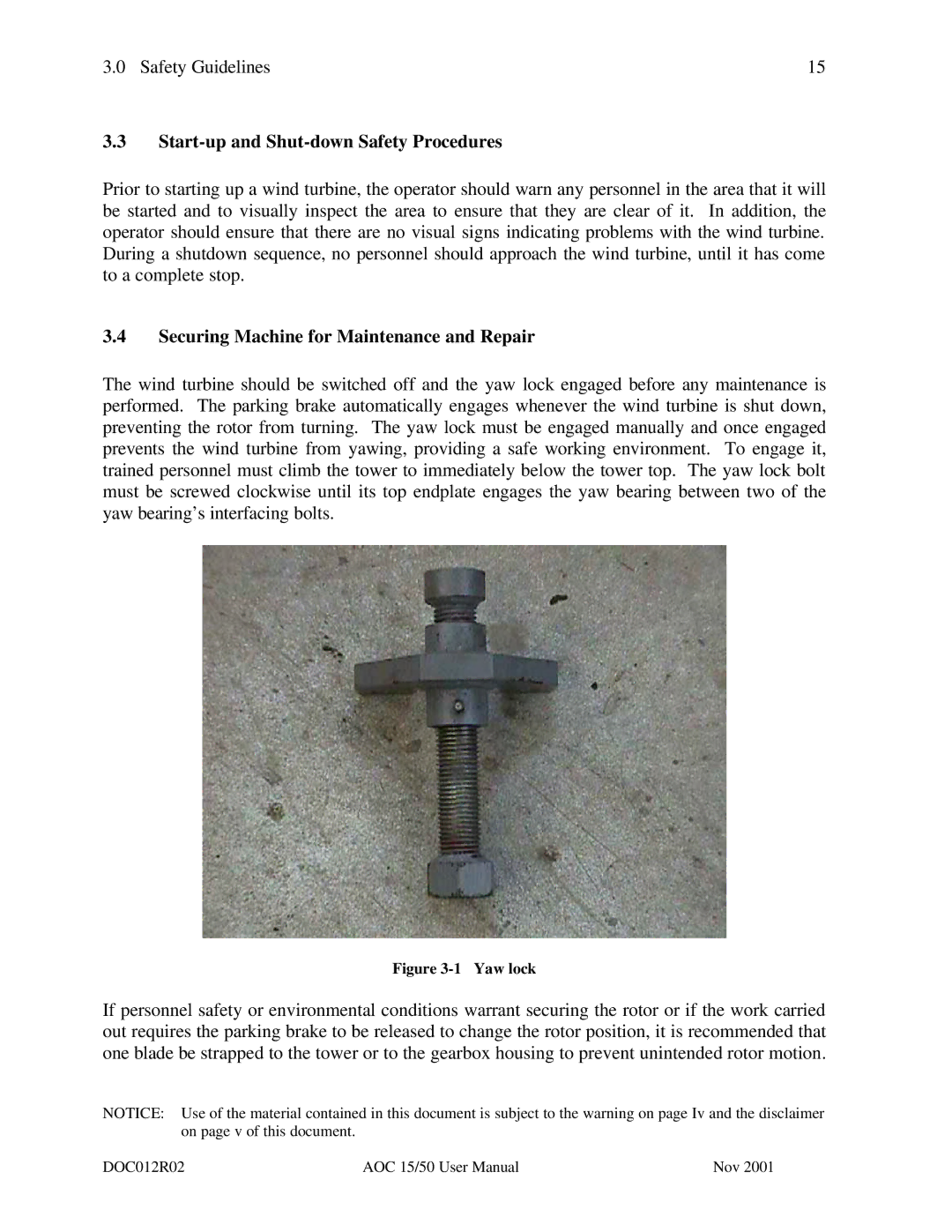

The wind turbine should be switched off and the yaw lock engaged before any maintenance is performed. The parking brake automatically engages whenever the wind turbine is shut down, preventing the rotor from turning. The yaw lock must be engaged manually and once engaged prevents the wind turbine from yawing, providing a safe working environment. To engage it, trained personnel must climb the tower to immediately below the tower top. The yaw lock bolt must be screwed clockwise until its top endplate engages the yaw bearing between two of the yaw bearing’s interfacing bolts.

Figure 3-1 Yaw lock

If personnel safety or environmental conditions warrant securing the rotor or if the work carried out requires the parking brake to be released to change the rotor position, it is recommended that one blade be strapped to the tower or to the gearbox housing to prevent unintended rotor motion.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer on page v of this document.

DOC012R02 | AOC 15/50 User Manual | Nov 2001 |