For Machines Mfg. Since 7/09 | O P E R A T I O N | EVS Toolroom Lathes |

H.Cutting Fluid Flow Control Lever: Controls the flow of cutting fluid from the nozzle.

I.Compound Slide Handwheel: Moves the compound slide forward or backward. Includes an

J.Carriage Lock Bolt: Secures the carriage in place for greater rigidity and accuracy when using the cross or compound slide for the machining operation.

K.Thread Dial: Indicates when to engage the half nut during threading operations.

L.Thread Dial Chart: Indicates on which thread dial reading to engage the half nut for specific inch or Whitworth thread pitches.

M.Spindle ON/OFF Lever: Starts, stops and reverses direction of spindle rotation.

N.Half Nut Lever: Engages and disengages the half nut for threading operations.

O.Apron: Houses the carriage gearing and internal components.

P.Quick Change Feed Direction Knob: Changes apron feed direction without having to stop the lathe and move the headstock feed direction lever.

Q.Feed Control Lever: Engages and disengages the cross feed and carriage feed gearing.

R.Manual Carriage Oil Pump: Draws oil from the apron case and lubricates the carriage and ways through various oil ports.

S.Cross Slide Handwheel: Moves the cross slide toward or away from the workpiece. Includes an

T.Carriage Handwheel: Moves the carriage from

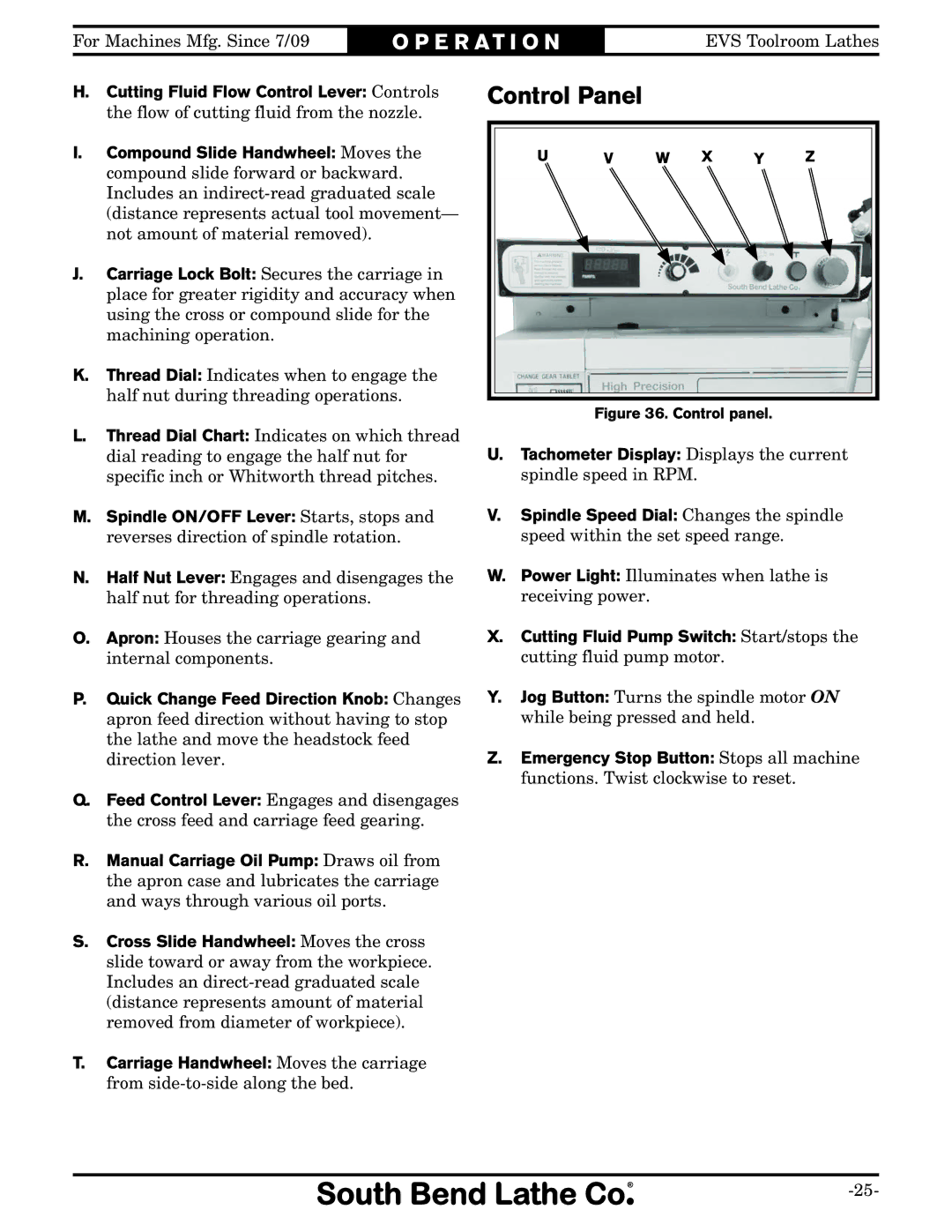

Control Panel

U V W X Y Z

Figure 36. Control panel.

U.Tachometer Display: Displays the current spindle speed in RPM.

V.Spindle Speed Dial: Changes the spindle speed within the set speed range.

W.Power Light: Illuminates when lathe is receiving power.

X.Cutting Fluid Pump Switch: Start/stops the cutting fluid pump motor.

Y.Jog Button: Turns the spindle motor ON while being pressed and held.

Z.Emergency Stop Button: Stops all machine functions. Twist clockwise to reset.