EVS Toolroom Lathes | M A I N T E N A N C E | For Machines Mfg. Since 7/09 |

Ball Oilers

Oil Type .. Mobil DTE Light or ISO 32 Equivalent

Oil Amount | 1 or 2 Drops |

Lubrication Frequency | Daily |

This lathe has five ball oiler locations (see Figures

Figure 118. Ball oiler locations.

Figure 119. Tailstock ball oiler locations.

To lubricate the ball oilers, clean the outside surface to remove any dust or grime, push the ball with the tip of the oil can nozzle, and squirt a small amount inside. If the lathe is in a moist or dirty environment, increase the oiling interval.

Cleaning Electrical Box Filter

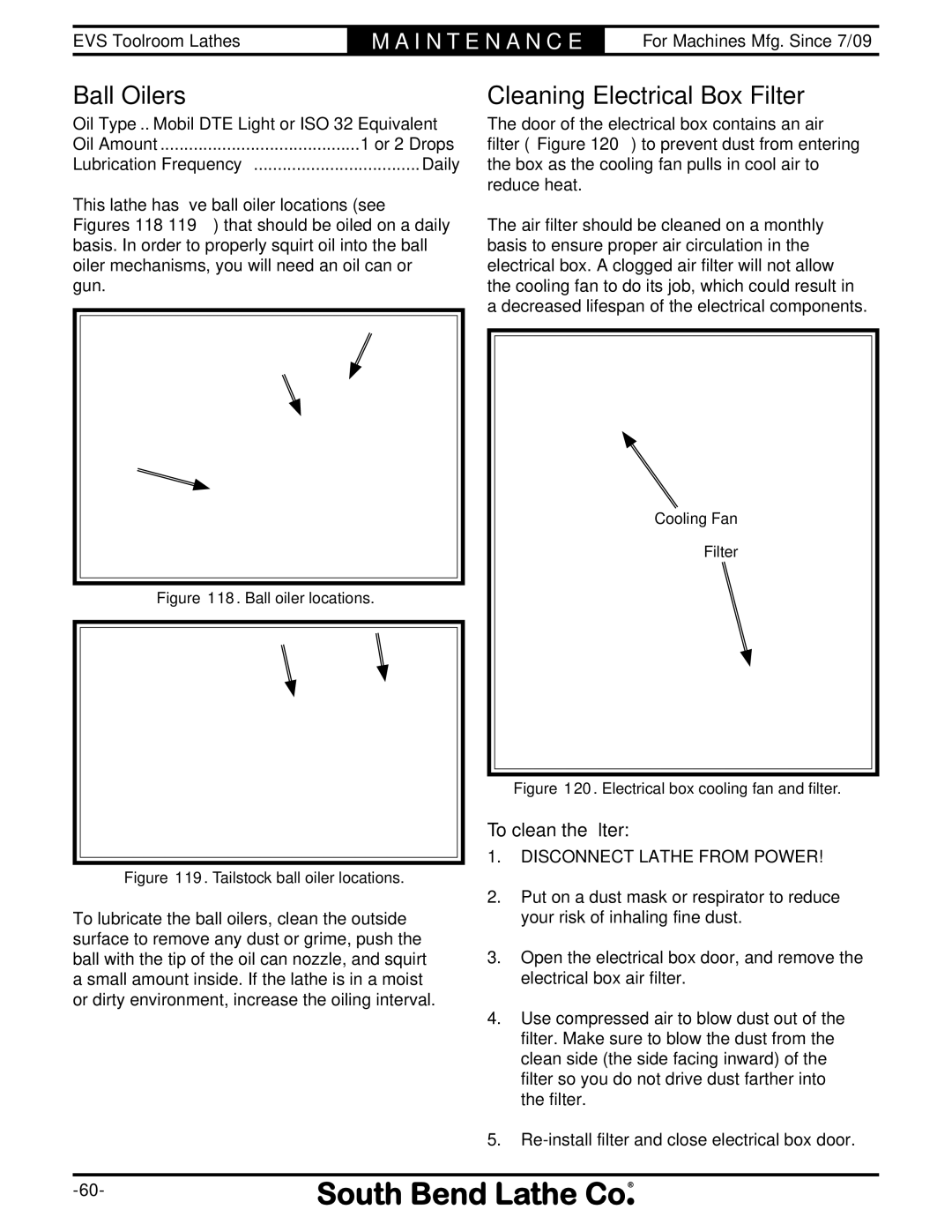

The door of the electrical box contains an air filter (Figure 120) to prevent dust from entering the box as the cooling fan pulls in cool air to reduce heat.

The air filter should be cleaned on a monthly basis to ensure proper air circulation in the electrical box. A clogged air filter will not allow the cooling fan to do its job, which could result in a decreased lifespan of the electrical components.

Cooling F![]()

![]() an

an

Filter

Figure 120. Electrical box cooling fan and filter.

To clean the filter:

1.DISCONNECT LATHE FROM POWER!

2.Put on a dust mask or respirator to reduce your risk of inhaling fine dust.

3.Open the electrical box door, and remove the electrical box air filter.

4.Use compressed air to blow dust out of the filter. Make sure to blow the dust from the clean side (the side facing inward) of the filter so you do not drive dust farther into the filter.

5.