EVS Toolroom Lathes | O P E R A T I O N | For Machines Mfg. Since 7/09 |

Understanding Thread & Feed Rate Chart

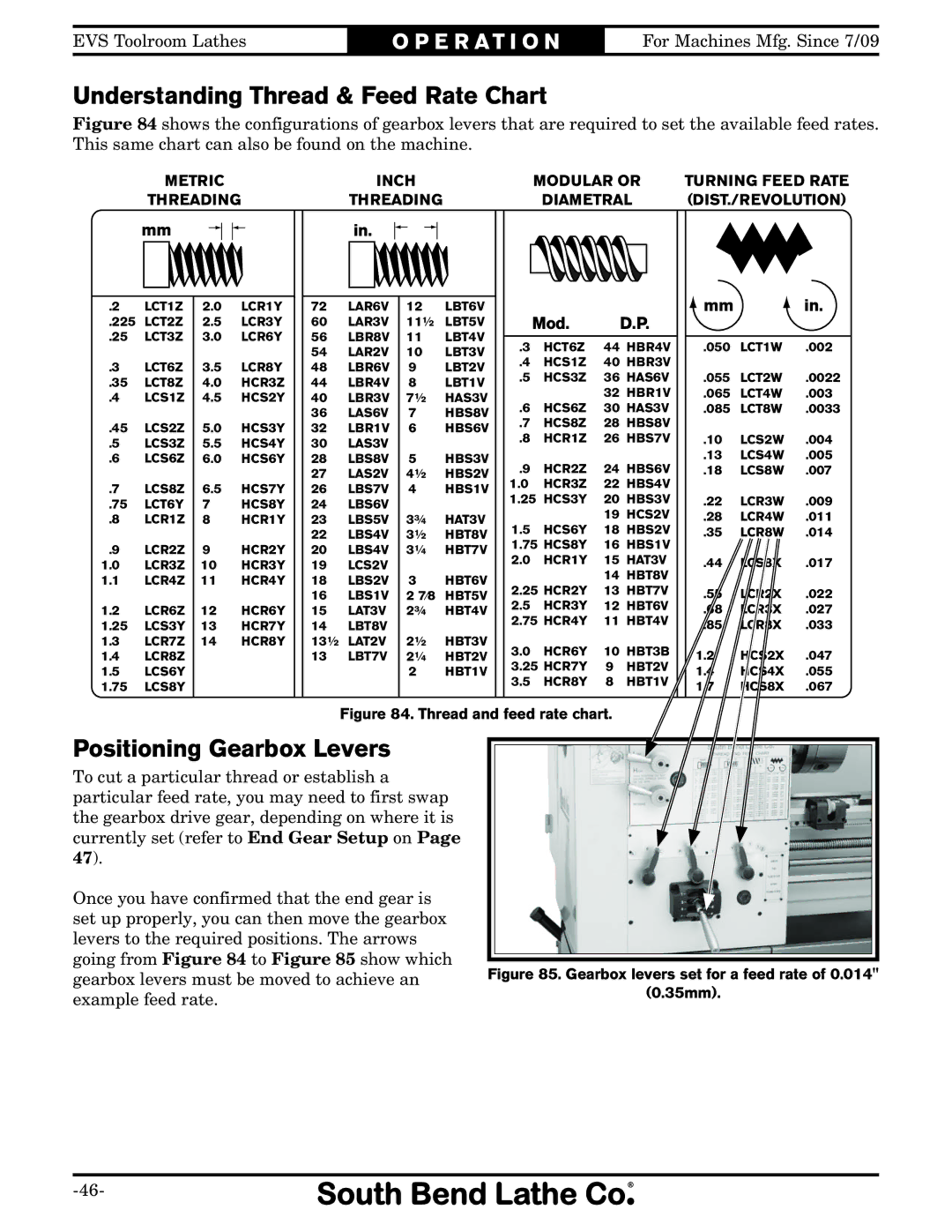

Figure 84 shows the configurations of gearbox levers that are required to set the available feed rates. This same chart can also be found on the machine.

METRIC

THREADING

INCH | MODULAR OR | TURNING FEED RATE |

THREADING | DIAMETRAL | (DIST./REVOLUTION) |

mm

.2 | LCT1Z | 2.0 | LCR1Y |

.225 | LCT2Z | 2.5 | LCR3Y |

.25 | LCT3Z | 3.0 | LCR6Y |

.3 | LCT6Z | 3.5 | LCR8Y |

.35 | LCT8Z | 4.0 | HCR3Z |

.4 | LCS1Z | 4.5 | HCS2Y |

.45 | LCS2Z | 5.0 | HCS3Y |

.5 | LCS3Z | 5.5 | HCS4Y |

.6 | LCS6Z | 6.0 | HCS6Y |

.7 | LCS8Z | 6.5 | HCS7Y |

.75 | LCT6Y | 7 | HCS8Y |

.8 | LCR1Z | 8 | HCR1Y |

.9 | LCR2Z | 9 | HCR2Y |

1.0 | LCR3Z | 10 | HCR3Y |

1.1 | LCR4Z | 11 | HCR4Y |

1.2 LCR6Z 12 HCR6Y

1.25 LCS3Y 13 HCR7Y

1.3 LCR7Z 14 HCR8Y

1.4LCR8Z

1.5LCS6Y

1.75LCS8Y

in.

72 | LAR6V | 12 | LBT6V |

60 | LAR3V | 11½ | LBT5V |

56 | LBR8V | 11 | LBT4V |

54 | LAR2V | 10 | LBT3V |

48 | LBR6V | 9 | LBT2V |

44 | LBR4V | 8 | LBT1V |

40 | LBR3V | 7½ | HAS3V |

36 | LAS6V | 7 | HBS8V |

32 | LBR1V | 6 | HBS6V |

30 | LAS3V |

|

|

28 | LBS8V | 5 | HBS3V |

27 | LAS2V | 4½ | HBS2V |

26 | LBS7V | 4 | HBS1V |

24 | LBS6V |

|

|

23 | LBS5V | 3¾ | HAT3V |

22 | LBS4V | 3½ | HBT8V |

20 | LBS4V | 3¼ | HBT7V |

19 | LCS2V |

|

|

18 | LBS2V | 3 | HBT6V |

16 | LBS1V | 2 7⁄8 | HBT5V |

15 | LAT3V | 2¾ | HBT4V |

14 | LBT8V |

|

|

13½ | LAT2V | 2½ | HBT3V |

13 | LBT7V | 2¼ | HBT2V |

|

| 2 | HBT1V |

|

|

|

|

Mod. D.P.

.3 HCT6Z 44 HBR4V

.4 HCS1Z 40 HBR3V

.5 HCS3Z 36 HAS6V

32 HBR1V

.6 HCS6Z 30 HAS3V

.7 HCS8Z 28 HBS8V

.8 HCR1Z 26 HBS7V

.9 HCR2Z 24 HBS6V

1.0HCR3Z 22 HBS4V

1.25HCS3Y 20 HBS3V

19 HCS2V

1.5HCS6Y 18 HBS2V

1.75HCS8Y 16 HBS1V

2.0HCR1Y 15 HAT3V 14 HBT8V

2.25 HCR2Y 13 HBT7V

2.5HCR3Y 12 HBT6V

2.75HCR4Y 11 HBT4V

3.0HCR6Y 10 HBT3B

3.25HCR7Y 9 HBT2V

3.5 HCR8Y 8 HBT1V

mm |

| in. |

|

|

|

.050 | LCT1W | .002 |

.055 | LCT2W | .0022 |

.065 | LCT4W | .003 |

.085 | LCT8W | .0033 |

.10 | LCS2W | .004 |

.13 | LCS4W | .005 |

.18 | LCS8W | .007 |

.22 | LCR3W | .009 |

.28 | LCR4W | .011 |

.35 | LCR8W | .014 |

.44 | LCS8X | .017 |

.55 | LCR2X | .022 |

.68 | LCR3X | .027 |

.85 | LCR8X | .033 |

1.2 | HCS2X | .047 |

1.4 | HCS4X | .055 |

1.7 | HCS8X | .067 |

|

|

|

Figure 84. Thread and feed rate chart.

Positioning Gearbox Levers

To cut a particular thread or establish a particular feed rate, you may need to first swap the gearbox drive gear, depending on where it is currently set (refer to End Gear Setup on Page 47).

Once you have confirmed that the end gear is set up properly, you can then move the gearbox levers to the required positions. The arrows going from Figure 84 to Figure 85 show which gearbox levers must be moved to achieve an example feed rate.