EVS Toolroom Lathes | O P E R A T I O N | For Machines Mfg. Since 7/09 |

Offsetting

The tailstock can be offset from the spindle center line for turning tapers. The offset movement is controlled by set screws on both sides of the tailstock (see Figure 57), and the amount of movement is indicated by the offset scale on the back of the tailstock.

Note: For a precise offset, use a dial indicator to check quill movement while adjusting screws.

Set Screw

(1 of 2)

Offset

Scale

Figure 57. Tailstock offset controls. |

|

Tool Needed | Qty |

Hex Wrench 6mm | 1 |

To offset the tailstock from the spindle center line, loosen the clamp bolts underneath the tailstock to relieve pressure on the sliding components, then rotate the set screws in the direction shown in Figure 58.

Turn | Turn | Turn | Turn |

CCW | CW | CW | CCW |

Figure 58. Set screw adjustment in relation to

tailstock movement.

Aligning

The offset of your lathe was aligned with the spindle center line at the factory. We recommend that you take the time to ensure that the tailstock is aligned to your own desired tolerances, especially if you have changed the offset to cut shallow tapers.

To align the tailstock offset to the spindle center line:

1.Use a precision level to make sure the bedway is level from

—If the bedway is not level, correct this condition before continuing with this procedure.

2.Obtain two pieces of steel round stock 2" in diameter and 6" long.

3.Center drill both ends of one piece of round stock, then set it aside for use in Step 6.

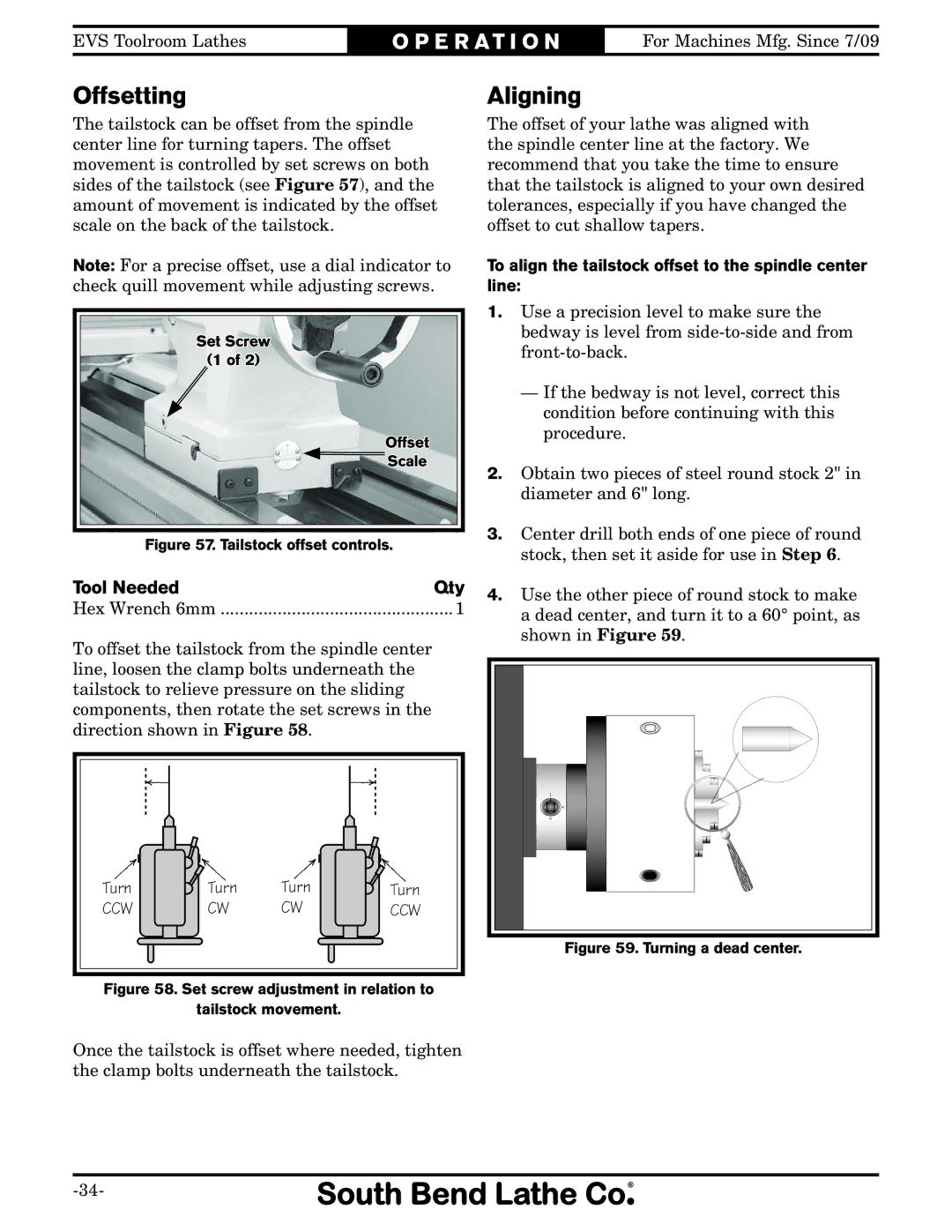

4.Use the other piece of round stock to make a dead center, and turn it to a 60° point, as shown in Figure 59.

Figure 59. Turning a dead center.

Once the tailstock is offset where needed, tighten the clamp bolts underneath the tailstock.