Cutter Slab Saws

Carr. Fed. Mexico-Puebla KM Tel

Stow Product Support Provided by Multiquip

Wilmington Ave Tel Carson, CA Fax Contact mq@multiquip.com

Fax Contact pmastretta@cipsa.com.mx

Stow Cutter 3 CE SAW Table of Contents

Stow Cutter 3 Slab SAW

Stow Cutter 3 CE SAW Specifications

Cutter 3 Push Cutter 3 Self-Propelled

Stow Cutter 3 CE SAW Engine Specifications

Stow Cutter 3 CE SAW Dimensions

You do not follow these directions

Stow Cutter 3 CE SAW Safety Message Alert Symbols

If you do not follow these directions

You can be Injured if you do not follow these directions

Always wear approved respiratory protection

Always wear approved eye and hearing protection

Stow Cutter 3 CE SAW Rules for Safe Operation

Rules for Safe Operation

General Safety

Diamond Blade Safety

Emergencies

Maintenance Safety

Saw Transportation Safety

Always know the location of the nearest first aid kit

Machine Safety Decals

Stow Cutter 3 Saw Decals

Stow Cutter 3 CE SAW General Information

Stow Cutter 3 CE SAW Major Components

Smoothly

Cannister to gain access to filter element

Stow Cutter 3 CE SAW 13HP Honda Engine Components

Flow of fuel

Fuel Filter Filters fuel for contaminants

Stow Cutter 3 CE SAW 20HP Honda Engine Components

Be shut down

Honda GX390 engine shown

Stow Cutter 3 CE SAW Inspection

Engine Oil Check

Honda 13 HP engine shown

Gasoline Check

Transmission Reservoir

Additionally, when connecting the positive

Battery Self-Propelled models only

Do not overfill the battery

Use only distilled water

Improper under cutting core protection

Pin

Continues, catastrophic failure will occur

Rotation downcuts with the turn of the shaft

Blade Speed

Stow Cutter 3 CE SAW Inspection Blade Placement

Diamond Blades

Inner flange collar

Set the engine ON/OFF switch to the OFF position

Flange

Tight closure on the surface of the blade

Belts and Covers

Guards and Covers Check

Institute Ansi B7.1 and B7.5

Belts Alignment and Tensioning

Following V-belt part numbers listed in Table

Stow Cutter 3 CE SAW Inspection Belts & Water Tank

Water Tank

Adjusting the Blade Height

Stow Cutter 3 CE SAW Inspection Adjustments

Adjusting the Handle Bars

Determining the Cut Depth

Both as an Emergency Engine

Stow Cutter 3 CE SAW Manual START-UP 13HP Honda Engine

HP Engine Manual Start

Engine ON/Off Switch Engine

Throttle Lever

Starter Grip

HP Engine Electric Start

Ensure the wheel clamps are in the Locked position. Figure

Engine Start Switch OFF Position

If the engine must be stopped in an emergency situation

Emergency Stop Procedure

Stow Cutter 3 CE SAW Operation

Traveling During Cutting Push

Neutral Position

Traveling During Cutting Self-Propelled

Place the travel lever in the Neutral position

Engage Position

Cutting

Turn water source on Figure

Extreme heat Restarting After Intervention

Finishing a Cut

Engine components can generate

Stopping the Engine Self-Propelled Models

Stow Cutter 3 CE SAW SHUT-DOWN Procedures

Stopping the Engine Push Model

Saw Blade Removal and Installation

Maintenance

General Cleanliness

Engine oil

Stow Cutter 3 CE SAW Maintenance

Contact

Retighten the adjustment nut

AdjustV-Belt Alignment/Replacement Pulleys

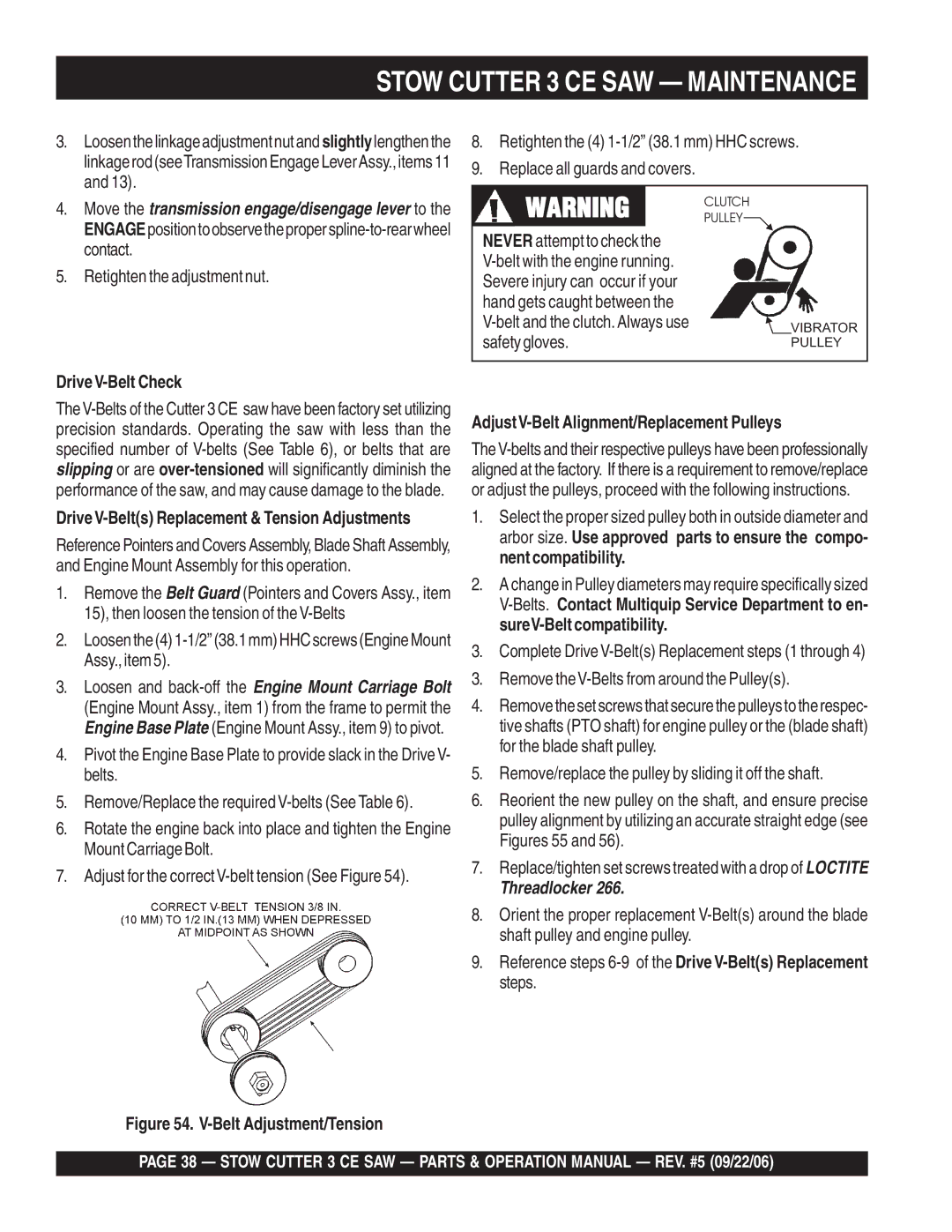

DriveV-Belt Check

Stow Cutter 3 CE SAW Maintenance

Battery Maintenance

Battery Electrolyte Levels

Decommissioning Saw/Components

Stow Cutter 3 CE SAW 13HP Enginewiring Diagram Recoil Start

Stow Cutter 3 CE SAW 20HP ENG.WIRING Diagram Electric Start

Stow Cutter 3 CE SAW -TROUBLESHOOTING Engine

Stow Cutter 3 CE SAW -TROUBLESHOOTING Engine

Engine Troubleshooting

Stow Cutter 3 CE SAW -TROUBLESHOOTING Blade

Items Found In the Items Number Column

How to read the marks and remarks used in this parts book

Items Found In the Remarks Column

Are subject to change without

Page

Stow Cutter 3 CE SAW Suggested Spare Parts

Description

Stow Cutter 3 CE SAW Name Plate and Decals

Name Plate and Decals

Stow Cutter 3 CE SAW Name Plate and Decals

Under Carriage Assy

WASHER, Flat SAE 3/4

AXLE, Rear & Front

FRAME, Undercarriagee Assy

Bearing Plain

Stow Cutter 3 CE SAW Blade Shaft Assy

Blade Shaft Assy

Stow Cutter 3 CE SAW Blade Shaft Assy

Lifting Bale Assy

BRACE, 13HP Bail

13HP, Lift Bale Assy

20HP, Lift Bail Assy

BRACE, 20HP Bail

Console ASSY. Push Models

Handle Assy

Housing ASSY., Yellow Stow

Console ASSY. Push

WASHER, Lock 3/8 MED

Stow Cutter 3 CE SAW Console ASSY. SELF-PROPELLED

Console ASSY. SELF- Propelled Models

Shift Control Assy

Housing ASSY., Stow Yellow

GRIP, 1 ID

COVER, Rear

13HP Honda Engine Mount Assy

NUT, HEX Finish 1/2-13

Engine Base Assy

20HP Honda Engine Mount Assy

Spacer

Stow Cutter 3 CE SAW 13HP Honda Engine Assy

13HP Honda Engine Assy

Stow Cutter 3 CE SAW 13HP Honda Engine Assy

ENGINE, Honda 13HP, GX390K1QWT2

20HP Honda Engine Assy

PULLEY, Transmission

ENGINE, Honda 20HP GX620TXF2

MOUNT, Idler Spring

Pointers and Covers Assy

Spanner Bushing CSI

Pointer and Covers Assy

Blade Guide Weldment

Pointer

Water System Assy

FITTING, Nipple 1/2MP X 2 Galv

Water System from Console SP

FITTING, Plastic 90 1/2MP X 1/2BARB

Bolt W/NUTS

Blade Guard Assy

Spring TENSION, Guard Blade

Connector 3/8

FITTING, Brass 1/2BARB X 3/4F Grdn

Pipe Strap 3/8

Stow Cutter 3 CE SAW Manual Raise and Lower Assy

Manual Raise and Lower Assy

BEARING, Flange

Jack Screw Assy Blade

Jackscrew

SPACER, Jackscrew

Battery Assy

STRAP, Ground

Bracket Battery

Battery Hold Down KIT

Stow Cutter 3 CE SAW -TRANSMISSION Engage Lever Assy

Transmission Engage Lever Assy

HYD. Transmission Engage Lever Assy

WASHER, Flat SAE 3/8

Hydrostatic Transmission

Stow Cutter 3 CE SAW Hydrostatictransmission Assy

Hydrostatic Transmission Assy

Stow Cutter 3 CE SAW Hydrostatic Drive Assy

Hydrostatic Drive Assy

Stow Cutter 3 CE SAW Hydrostatic Drive Assy

WASHER, Fibre

AIR Cleaner Assy

COLLAR, AIR Cleaner

SEAL, AIR Cleaner Cover

GROMMET, AIR Cleaner

Collar B, AIR Cleaner

Camshaft Assy

ARM, Valve Rocker

SPRING, Weight Return

ROD, Push

LIFTER, Valve

Carburetor Assy

Valve SET, Float

PLATE, Lever Setting

Gasket SET

Float SET

Control Assy

SPRING, Governor

ARM, Governor

ROD, Governor

SPRING, Throttle Return

Crankcase Cover Assy

PIN, Governor Weight

WEIGHT, Governor

HOLDER, Governor Weight

GASKET, Case Cover

Crankshaft Assy

WEIGHT, Balancer

Cylinder Barrel Assy

BOLT, Drain Plug

Switch ASSY., OIL Level

SHAFT, Governor ARM

OIL Seal

Cylinder Head Assy

GASKET, Cylinder Head

GUIDE, Valve OS Optional

CLIP, Valve Guide

COVER, Head

FAN Cover Assy

COVER, FAN *NH1* Black

Switch ASSY., Engine Stop

CLIP, Tube

Shroud

Flywheel Assy

NUT, Special 16MM

FAN, Cooling

Flywheel

Fuel Tank Assy

TANK, Fuel *NH1* Black

RUBBER, Supporter 107MM

JOINT, Fuel Tank

GASKET, Fuel Filler CAP

Ignition Coil Assy

CLIP, Wire Harness

GROMMET, Wire

WIRE, Stop Switch 430MM

Coil ASSY., Ignition

Muffler 1 Assy

PIPE, EX

Muffler

PROTECTOR, Muffler

CAP, Muffler

Piston Assy

Ring SET, Piston 0.75 Nippon

BOLT, Connecting ROD

Ring SET, Piston STD

Piston STD

Recoil Starter Assy

SPRING, Friction

PULLEY, Recoil Starter

RATCHET, Starter

SPRING, Starter Return

Labels Assy

Emblem

LABEL, AIR Cleaner Caution

MARK, AIR Cleaner Sales Point

LABEL, Caution

Honda GX620TXF2 Engine AIR Cleaner Assy

ELEMENT. AIR Cleaner

HOLDER, AIR CLEANER, Upper

HOLDER, AIR CLEANER, Lower

COVER, AIR Cleaner

Honda GX620TXF2 Engine Camshaft Assy

PIN A, Decompression

SHAFT, Rocker ARM

HOLDER, Decompression PIN

PIN B, Decompression

Honda GX620TXF2 Engine Control Assy

Spring Governor

JOINT, ROD

SPRING, Starter

Spring ,THROTTLE Return

Control BOX Assy

CASE, Control

SUB-WIRE Harness Assy

HOLDER, Stop Switch Wire

BRACKET, Case Mounting

Honda GX620TXF2 Engine Crankcase Cover Assy

SCREEN, OIL Filter

SPRING, Relief Valve

COVER, OIL Filter

DIPSTICK, OIL

Honda GX620TXF2 Engine Crankshaft Assy

CRANKSHAFT, T-TYPE

Honda GX620TXF2 Engine Cylinder Barrel Assy

COVER, Breather

COLLAR, Filter Setting

CLAMP, Wire

VALVE, Breather

Honda GX620TXF2 Engine Cylinder Head Assy

CAP, OIL

COVER, Head Filler

GASKET, Head Cover

MANIFOLD,

Honda GX620TXF2 Engine FAN Cover Assy

HOOD, FAN Cover

PLATE, R Side

PLATE, L Side

PLUG, FAN Cover Hole

Honda GX620TXF2 Engine Flywheel Assy

NUT, Flange 20MM

PLATE, Cooling FAN Start

GRID, Screen P.T.O

WASHER, 20MM

Honda GX620TXF2 Engine Ignition Coil Assy

Coil ASSY., L. Ignition

GROMMET, Ignition Wire

Coil ASSY., R. Ignition

Coil ASSY., Charghe

Muffler Assy

Band ASSY. Optional

MUFFLER, High Optional

PIPE, EX. HIGH-L Optional

BOLT, Flange 6X8 Optional

Honda GX620TXF2 Engine Piston and Connecting ROD Assy

Piston & Connecting ROD Assy

Optional

NUT, Connecting ROD

Ring SET, Piston Standard

Piston

Honda GX620TXF2 Engine Fueltank Assy

CAP, Fuel

Fuel Tank

SUPPORT, Fuel Tank

COLLAR, FR. Engine Hanger

Fuel Pump Assy

FILTER, Fuel

Pump ASSY., Fuel

STAY, Fuel Pump

BASE, Clip

Honda GX620TXF2 Engine Carburetor Assy

Screw Washer

GASKET, AIR Cleaner

Screw SET, Drain

CAP, Choke Lever Dust

Starter Motor Assy

Gear SET, Pinion

Cover A. Magnetic Switch

NUT, Washer 6MM

Armature

No Artwork Available

Gasket KIT Assy

061A1ZJ1000

Label Assy

LABEL, Specification GX620

MARK, EMBLEM, GX620

Terms and Conditions of Sale Stow Construction Equipment

Page

Tel 339 Fax 0161 339 Contact kcassell@multiquip.com.uk

![]() WARNING

WARNING![]()

![]() VIBRATOR

VIBRATOR